Mobile:+86-311-808-126-83

Email:info@ydcastings.com

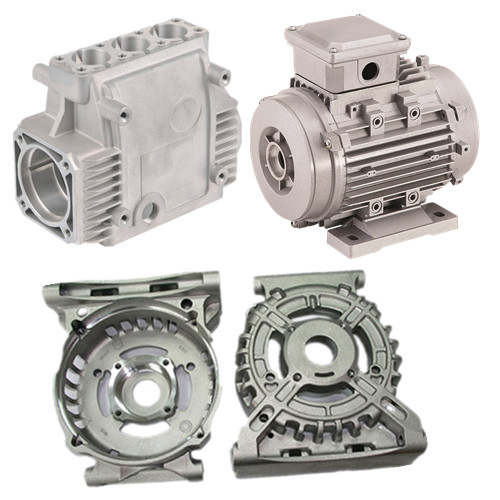

impeller vane

Understanding Impeller Vanes Design and Functionality

Impeller vanes play a critical role in various engineering applications, particularly in centrifugal pumps, compressors, and turbines. These curved blades are designed to impart kinetic energy to a fluid, facilitating its movement through a system. The design, shape, and arrangement of impeller vanes directly influence the efficiency and performance of the equipment they are part of.

The primary function of impeller vanes is to convert rotational energy from a motor or engine into fluid energy. When the impeller rotates, the vanes push the fluid outward, increasing its velocity and pressure. This increase is vital for numerous applications, from water transfer in municipal systems to the operation of jet engines.

The design of impeller vanes involves intricate considerations, including the angle, thickness, and curvature of each blade

. These factors determine the flow characteristics, such as the level of turbulence and the energy transfer efficiency. For instance, a higher angle of attack can increase the flow rate but may also lead to a risk of cavitation, a phenomenon where bubbles form and collapse, causing significant damage to the impeller over time.impeller vane

Different applications require specific vane designs. In centrifugal pumps, for instance, closed vanes are often employed to enhance fluid containment and efficiency. Conversely, open vanes are common in applications where the fluid being transferred contains solids, as they minimize the risk of clogging. The materials used for manufacturing impeller vanes also vary, with options ranging from stainless steel for high durability to plastics for lighter, corrosion-resistant applications.

Efficiency is a crucial metric when evaluating impeller vane performance. The relationship between the impeller speed, the fluid's density, and the vane's geometry defines the overall system efficiency. Engineers utilize computational fluid dynamics (CFD) simulations to predict performance and optimize designs before physical production. Such simulations allow for the refinement of vane design, reducing energy losses and improving operational reliability.

Maintenance of impeller vanes is essential to ensure long-lasting performance. Regular inspections can identify wear and tear, leading to timely replacements or repairs. In environments where cavitation is a risk, special coatings or materials can be employed to mitigate damage.

In conclusion, impeller vanes are integral components in systems where fluid movement is required. Their design and manufacturing processes are vital for the efficient operation of various machines. Understanding their functionality and maintenance needs is essential for engineers and operators alike, ensuring that these systems remain efficient and reliable over time. As technology advances, the potential for innovative designs and materials will further enhance the performance of impeller vanes, driving efficiency in fluid transport systems.

-

Understanding Metal Casting TechniquesNewsApr.02,2025

-

Understanding Exhaust Manifolds for Enhanced Engine PerformanceNewsApr.02,2025

-

The World of Metal FabricationNewsApr.02,2025

-

Key Components for Pump and Turbo EfficiencyNewsApr.02,2025

-

Essential Tools for Automotive Maintenance and RepairNewsApr.02,2025

-

Durable Valve Components for Effective Water ManagementNewsApr.02,2025