Mobile:+86-311-808-126-83

Email:info@ydcastings.com

Impeller Bronze

The Significance of Bronze Impellers in Modern Engineering

In the world of modern engineering, the choice of materials is crucial to ensuring the efficiency and durability of machinery. Among the various materials used, bronze stands out, particularly in the manufacturing of impellers. Bronze impellers have become an essential component in various applications due to their unique properties, which enhance performance and longevity.

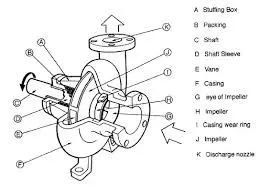

Bronze, an alloy primarily consisting of copper and tin, is renowned for its excellent corrosion resistance and strength. These qualities make bronze an ideal choice for impellers, which are vital components in pumps, turbines, and other fluid mechanics applications. When fluid flows through these devices, impellers are responsible for converting rotational energy into fluid movement, affecting the overall efficiency of the system. Therefore, selecting the right material is paramount.

The Significance of Bronze Impellers in Modern Engineering

Moreover, bronze impellers are known for their superior wear resistance. In environments where sand, sediment, and other abrasive particles are present, the durability of the impeller becomes critical. Bronze's hardness allows it to maintain its shape and function in such challenging conditions, ensuring consistent performance. This characteristic is particularly important in applications like marine propulsion systems and water treatment plants, where reliability is imperative.

impeller bronze

In addition to its mechanical properties, the aesthetic appeal of bronze cannot be overlooked. The alloy’s warm golden hue can be advantageous in decorative applications or exposed installations, providing both functionality and visual appeal. This dual benefit sees bronze impellers being utilized in not only industrial setups but also in architectural water features and aesthetic-focused installations.

Additionally, advancements in manufacturing technologies have allowed for the production of precision-engineered bronze impellers. Techniques such as computer numerical control (CNC) machining ensure high levels of accuracy in the dimensions and shapes of impellers. This precision enhances the hydrodynamic performance of the impeller, leading to improved efficiency and reduced energy consumption in fluid systems.

While bronze impellers offer numerous advantages, it is essential to consider the application context. Factors such as temperature, type of fluid, and flow rates must all be considered during the selection process. Engineers and manufacturers must work closely to determine whether bronze is the most suitable option based on these variables.

In conclusion, bronze impellers play a vital role in modern engineering, providing unmatched corrosion resistance, wear durability, and aesthetic appeal. As industries continue to evolve and demand higher efficiency and reliability, the significance of materials like bronze cannot be overstated. Its application in impellers is a testament to the timeless relevance of this alloy, offering solutions that meet the rigorous demands of today’s engineering challenges. The future of impeller technology looks promising, with bronze continuing to hold a central position in this dynamic field.

-

Understanding Metal Casting TechniquesNewsApr.02,2025

-

Understanding Exhaust Manifolds for Enhanced Engine PerformanceNewsApr.02,2025

-

The World of Metal FabricationNewsApr.02,2025

-

Key Components for Pump and Turbo EfficiencyNewsApr.02,2025

-

Essential Tools for Automotive Maintenance and RepairNewsApr.02,2025

-

Durable Valve Components for Effective Water ManagementNewsApr.02,2025