Mobile:+86-311-808-126-83

Email:info@ydcastings.com

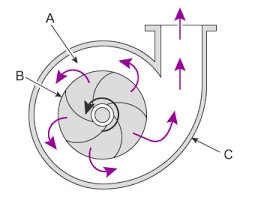

impeller

In the world of fluid dynamics, the impeller stands as a key innovation driving efficiency and efficacy across various industrial applications. This intricate component, often crafted from robust materials like stainless steel or specialized ceramics, is used in pumps to move fluids through centrifugal force. The design and function of an impeller are crucial not only for enhancing performance but also for ensuring durability and longevity in challenging environments.

Experience has shown that selecting the right impeller can significantly improve the efficiency of a pump system. In industrial settings, for instance, a well-chosen impeller can reduce energy consumption and operational costs. As such, understanding the specific requirements of your system is paramount. This involves assessing the type of fluid, the required flow rate, and the operating conditions. Real-world applications have demonstrated that a mismatch in these parameters could lead to issues such as cavitation, reduced flow, or increased wear and tear.

From a professional standpoint, the science behind impeller design is deeply rooted in fluid mechanics. Different industries require unique impeller designs—ranging from axial flow impellers, which are ideal for low-pressure, high-flow applications, to radial impellers, which cater to high-pressure, low-flow needs. Understanding these design principles requires not only theoretical knowledge but also practical expertise in industrial dynamics. An expert would consider factors like impeller diameter, blade design, and rotational speed to tailor solutions that meet specific demand conditions.

In the realm of authority, well-regarded manufacturers continuously innovate to optimize impeller designs. These manufacturers are often on the frontier of research and development, crafting impellers that maximize performance while minimizing environmental impact. By integrating advanced computational fluid dynamics (CFD) software into the design process, these companies ensure precise simulations and testing, thus leading to more reliable and efficient products. Such advancements not only bolster performance metrics but also establish these manufacturers as authorities in fluid management systems.

Trustworthiness in the impeller market is built through rigorous testing and quality assurance. Reputable suppliers adhere to international standards such as ISO 9001, ensuring that each product has been meticulously evaluated for defects and performance flaws. Transparent communication regarding material specifications, tolerances, and testing procedures further increases trust among consumers. Case studies and customer testimonials often underline the reliability of these products, offering insights into real-world performance and long-term satisfaction.

In conclusion, the impeller is more than just a component of a pump—it's an integral part of efficient fluid dynamics solutions. This vital piece of equipment is steeped in a tradition of engineering expertise and continuous innovation. By emphasizing the importance of experience, expertise, authority, and trustworthiness in product selection and utilization, industries can harness the full potential of impellers to improve operational efficiency and sustainability. As technology advances, the evolution of impeller designs is poised to meet the increasing demands of modern industries, proving once again that in the seamless flow of fluids, the impeller plays an indispensable role.

-

Why Should You Invest in Superior Pump Castings for Your Equipment?NewsJun.09,2025

-

Unlock Performance Potential with Stainless Impellers and Aluminum End CapsNewsJun.09,2025

-

Revolutionize Your Machinery with Superior Cast Iron and Aluminum ComponentsNewsJun.09,2025

-

Revolutionize Fluid Dynamics with Premium Pump ComponentsNewsJun.09,2025

-

Optimizing Industrial Systems with Essential Valve ComponentsNewsJun.09,2025

-

Elevate Grid Efficiency with High-Precision Power CastingsNewsJun.09,2025