Mobile:+86-311-808-126-83

Email:info@ydcastings.com

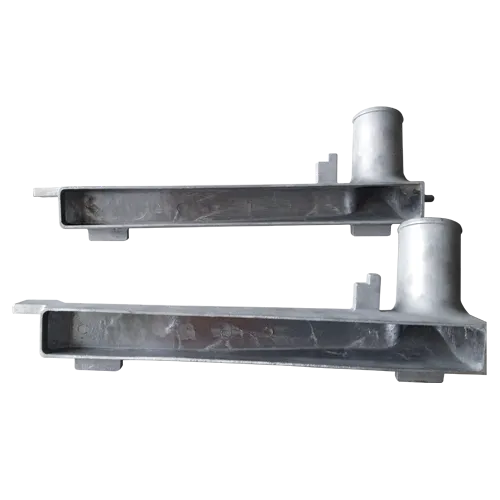

horizontal split casing

Understanding Horizontal Split Casing An In-Depth Look

In the world of engineering, particularly in the field of pump design and manufacturing, horizontal split casing pumps have garnered significant attention. These pumps are pivotal in a variety of applications, ranging from water supply systems to industrial processes. Their unique design and operational advantages make them a popular choice in many scenarios.

What is a Horizontal Split Casing Pump?

A horizontal split casing pump is a type of centrifugal pump that features a casing that is split horizontally, allowing for easy access to the internals of the pump without the need to remove the entire unit from its installation site. This distinctive casing design consists of two halves that are bolted together around the pump's impeller and volute. When these halves are separated, maintenance and inspections can be performed quickly and efficiently, offering significant operational benefits.

Key Features and Advantages

1. Ease of Maintenance One of the most significant advantages of horizontal split casing pumps is the ease of maintenance they provide. With the pump casing split horizontally, technicians can remove the upper half to access the impeller, mechanical seals, and other components without disturbing the piping system connected to the pump. This feature translates to reduced downtime and maintenance costs.

2. Superior Performance Horizontal split casing pumps are designed to handle high flow rates while maintaining efficiency. They can operate under varying conditions, making them suitable for a broad range of applications. The design allows for a balanced distribution of hydraulic forces, which minimizes vibration and wear over time.

3. Robust Construction These pumps are typically constructed from high-quality materials that withstand corrosion, wear, and thermal stress. The robustness of the materials used in their construction ensures a longer lifespan and reliability, which are crucial in critical industrial applications.

horizontal split casing

4. Versatility Horizontal split casing pumps are incredibly versatile, capable of pumping various fluids, including water, chemicals, and slurry. They are commonly utilized in water supply, irrigation, fire protection systems, and various industrial processes. Their flexibility in dealing with different media types without extensive modifications is a clear benefit over other pump designs.

5. Efficiency The pump's hydraulic design maximizes fluid flow while minimizing turbulence, which enhances the overall energy efficiency of the system. This design characteristic is crucial in applications where energy consumption is a significant concern, helping operators to reduce their carbon footprint and operational costs.

Applications

Due to their robust design and operational efficiency, horizontal split casing pumps are employed in numerous settings, including

- Municipal Water Supply These pumps are widely used in municipal water treatment and distribution systems, where they efficiently move large volumes of water to meet community needs. - Industrial Processes Many industries, including oil and gas, power generation, and manufacturing, use horizontal split casing pumps for handling and transferring fluids critical to their operations. - Fire Fighting Systems Horizontal split casing pumps are integral to fire protection systems, where reliability and high water flow rates are essential for effective firefighting.

Conclusion

In conclusion, horizontal split casing pumps represent a significant advancement in pump technology, merging efficiency, maintainability, and versatility. Their distinctive design aids in simplifying maintenance routines while retaining robust performance across a wide array of applications. As industries evolve and the demand for sustainable and efficient fluid transfer solutions grows, horizontal split casing pumps are likely to remain a staple in engineering designs. Their ability to handle high capacity demands while minimizing operational costs positions them as a leading choice among pump technologies for future installations and upgrades. Embracing these innovations will help industries optimize their processes and contribute to a more efficient future.

-

Why Should You Invest in Superior Pump Castings for Your Equipment?NewsJun.09,2025

-

Unlock Performance Potential with Stainless Impellers and Aluminum End CapsNewsJun.09,2025

-

Revolutionize Your Machinery with Superior Cast Iron and Aluminum ComponentsNewsJun.09,2025

-

Revolutionize Fluid Dynamics with Premium Pump ComponentsNewsJun.09,2025

-

Optimizing Industrial Systems with Essential Valve ComponentsNewsJun.09,2025

-

Elevate Grid Efficiency with High-Precision Power CastingsNewsJun.09,2025