Mobile:+86-311-808-126-83

Email:info@ydcastings.com

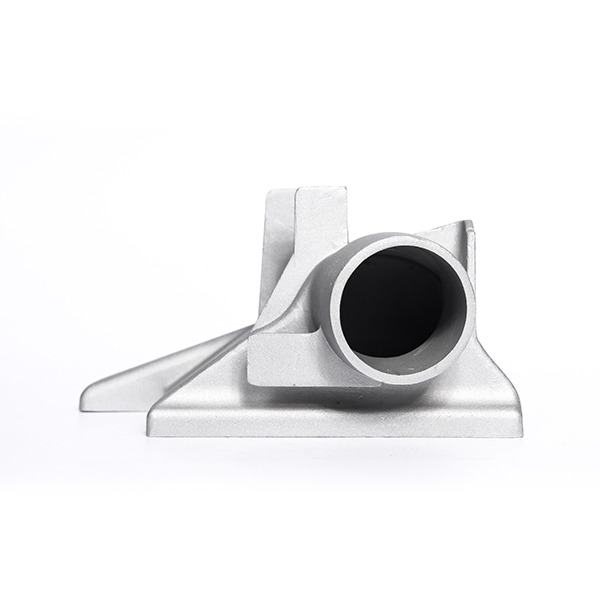

gravity casting aluminium

The Advantages and Process of Gravity Casting Aluminum

Gravity casting is a highly efficient and cost-effective method used for producing intricate metal components, particularly in aluminum manufacturing. This technique uses gravity to fill a mold with molten aluminum, making it a favored choice in industries that require precision and durability in their products.

Understanding the Gravity Casting Process

The gravity casting process begins with creating a mold that matches the desired shape of the finalized aluminum component. Molds can be made of various materials, including steel, iron, or sand, depending on the production needs and component specifications. Once the mold is prepared, it is heated to a predetermined temperature, allowing for better metal flow and reduced thermal shock.

Molten aluminum, typically produced from aluminum ingots or scrap, is then poured into the mold under the influence of gravity. The use of gravity significantly minimizes the air entrapment that can occur during the casting process, leading to higher quality and denser products. Once the aluminum has cooled and solidified, the mold is removed to reveal the cast part, which may require finishing processes such as machining, grinding, or surface treatment to meet precise specifications.

Benefits of Gravity Casting Aluminum

1. High Dimensional Accuracy One of the primary benefits of gravity casting is its ability to produce parts with excellent dimensional accuracy and surface finish. The controlled pouring process reduces the risk of defects, ensuring that the final products meet stringent tolerance requirements.

2. Material Efficiency Aluminum casting via gravity results in minimal waste. The process allows for the recycling of excess aluminum, which can be melted down and reused. This sustainability aspect not only lowers material costs but also contributes to environmentally friendly manufacturing practices.

gravity casting aluminium

3. Strength and Durability Aluminum parts produced using gravity casting are renowned for their strength and resistance to corrosion. The inherent properties of aluminum make it an ideal choice for applications requiring lightweight materials that do not compromise on durability.

4. Cost-Effective for Medium to High Production Volumes Gravity casting is especially advantageous for medium to high production runs. The initial setup costs can be higher due to the mold preparation; however, the overall cost per unit decreases significantly with larger production volumes.

5. Versatility Gravity casting is suitable for a wide range of aluminum alloys, allowing manufacturers to choose materials best suited for specific applications. This versatility helps in meeting various industry demands, whether for automotive parts, electronic housings, or structural components.

6. Faster Production Cycle The gravity casting process can be faster than other methods such as die casting, especially when dealing with less complex shapes. The cooling times can be optimized, leading to quicker turnaround times for production.

Applications of Gravity Cast Aluminum

Due to its numerous advantages, gravity casting aluminum is widely used in many sectors, including automotive, aerospace, marine, and consumer products. The ability to produce lightweight yet strong components makes it ideal for manufacturing engine parts, transmission cases, housing for electrical equipment, and decorative fixtures.

Conclusion

In summary, gravity casting aluminum is a powerful manufacturing process that combines efficiency with precision, leading to strong and reliable components across various industries. As technology advances, the techniques surrounding gravity casting continue to evolve, ensuring that manufacturers can meet the ever-increasing demands for quality and accuracy in metal casting. Its cost-effectiveness, material efficiency, and versatility position it as a key player in modern manufacturing processes.

-

Why Should You Invest in Superior Pump Castings for Your Equipment?NewsJun.09,2025

-

Unlock Performance Potential with Stainless Impellers and Aluminum End CapsNewsJun.09,2025

-

Revolutionize Your Machinery with Superior Cast Iron and Aluminum ComponentsNewsJun.09,2025

-

Revolutionize Fluid Dynamics with Premium Pump ComponentsNewsJun.09,2025

-

Optimizing Industrial Systems with Essential Valve ComponentsNewsJun.09,2025

-

Elevate Grid Efficiency with High-Precision Power CastingsNewsJun.09,2025