Mobile:+86-311-808-126-83

Email:info@ydcastings.com

end cover

The Significance of End Covers in Various Applications

In the realm of engineering and design, end covers play a crucial role in ensuring the functionality and durability of machinery, devices, and enclosures. These components, often overlooked, serve as protective barriers and aesthetic finishes in various applications. Understanding their importance can help industries enhance product longevity and efficiency.

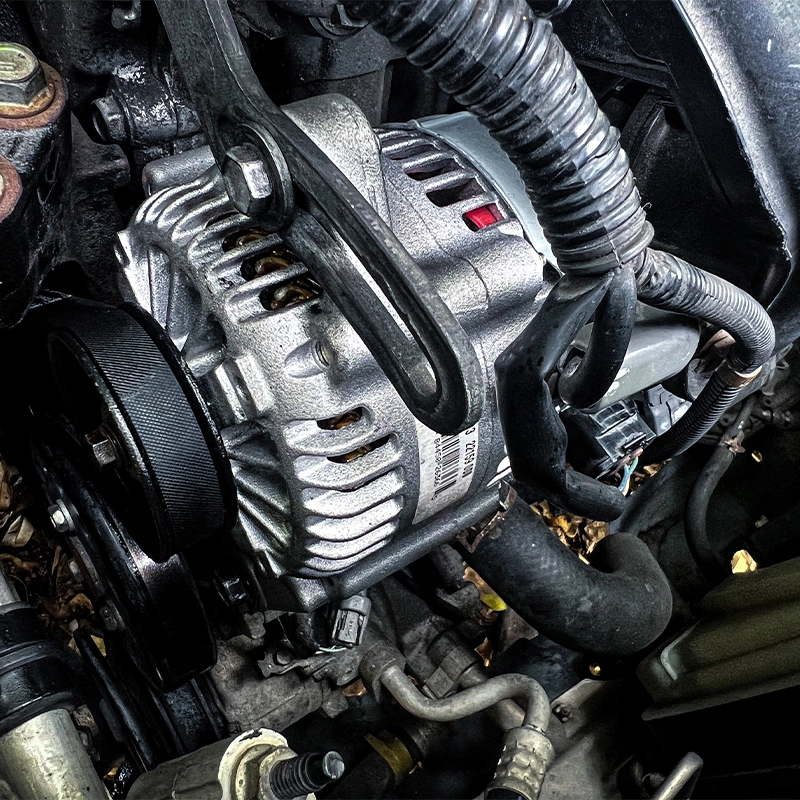

End covers are typically found in mechanical assemblies, electrical enclosures, and even furniture design. Their primary function is to protect the internal components from environmental factors such as dust, moisture, and mechanical damage. For example, in electric motor applications, end covers shield the rotor and stator from external contaminants, which can cause inefficiencies or even complete system failures. The necessity of these covers extends to safety as well; they prevent accidental contact with moving parts, minimizing the risk of injuries.

In the automotive industry, end covers provide critical protection for sensitive electronic components found in modern vehicles

. As cars become increasingly reliant on advanced technologies, the need for robust protective measures has never been greater. End covers made from high-performance plastics or metals not only shield components from debris and weather conditions but also play a role in thermal management. By maintaining the optimal operating temperature of electronic systems, these covers help enhance the overall performance and reliability of the vehicle.end cover

Moreover, end covers contribute to the aesthetic appeal of products. In consumer electronics, for instance, sleek and stylish end covers can significantly affect a product's marketability. Designers often prioritize the appearance of end covers, using materials that offer both durability and visual attraction. This blend of function and form is important in a competitive market, as consumers increasingly favor products that embody both quality and style.

Another critical aspect of end covers is their role in facilitating maintenance and repair. In many industrial applications, the ease of accessing internal components can greatly reduce downtime and maintenance costs. With well-designed end covers, technicians can quickly open a device for servicing, ensuring that machinery operates smoothly and efficiently. This ease of access is particularly vital in sectors where unplanned outages can lead to significant financial losses, such as manufacturing and utilities.

Despite their importance, the design and production of end covers are often held back by cost considerations. Manufacturers frequently face the challenge of creating end covers that are both inexpensive and durable. However, advancements in materials science and fabrication techniques have opened new avenues. For instance, innovations like 3D printing allow for customized, cost-effective end cover designs that do not compromise on quality. By investing in such technologies, companies can produce end covers that meet specific application needs while remaining budget-friendly.

In conclusion, end covers are indispensable components in various industries. They not only protect vital internal parts but also enhance the aesthetic and functional aspects of products. As industries continue to evolve, the design and manufacturing innovations surrounding end covers will play a critical role in meeting the demands of modern applications. Emphasizing the importance of these seemingly minor components can lead to improved product development strategies, resulting in more efficient and reliable solutions across the board. Ultimately, recognizing and investing in the significance of end covers will yield tremendous benefits, paving the way for enhanced performance and safety in countless applications.

-

Why Should You Invest in Superior Pump Castings for Your Equipment?NewsJun.09,2025

-

Unlock Performance Potential with Stainless Impellers and Aluminum End CapsNewsJun.09,2025

-

Revolutionize Your Machinery with Superior Cast Iron and Aluminum ComponentsNewsJun.09,2025

-

Revolutionize Fluid Dynamics with Premium Pump ComponentsNewsJun.09,2025

-

Optimizing Industrial Systems with Essential Valve ComponentsNewsJun.09,2025

-

Elevate Grid Efficiency with High-Precision Power CastingsNewsJun.09,2025