Mobile:+86-311-808-126-83

Email:info@ydcastings.com

Aluminum End Caps for Secure Sealing and Enhanced Protection in Various Applications

Exploring the Benefits and Applications of Aluminum End Caps

Aluminum end caps are gaining significant attention in various industries due to their durability, lightweight properties, and versatility. These components are essential in protecting open ends of pipes, tubes, and containers. Their unique characteristics make them an ideal choice for manufacturers engaged in diverse applications ranging from construction to automotive and even aerospace.

What are Aluminum End Caps?

Aluminum end caps are closed fittings designed to cover the open ends of pipes or tubes. They serve as protective covers that prevent contamination, ingress of moisture, and physical damage. These caps are commonly manufactured through processes like extrusion and stamping, leading to a range of sizes and shapes tailored for specific applications. Their designs ensure a snug fit, providing a secure seal while maintaining structural integrity.

Advantages of Aluminum End Caps

1. Lightweight and Strong One of the primary advantages of aluminum is its low density, making aluminum end caps significantly lighter than their counterparts made of steel or other metals. This lightweight nature leads to reduced shipping costs and ease of handling, especially for large-scale projects. Despite their lightness, aluminum end caps offer impressive strength and resistance to deformation.

2. Corrosion Resistance Aluminum end caps have excellent resistance to corrosion, particularly from environmental factors. This makes them ideal for outdoor applications or in environments where exposure to moisture and chemicals is a concern. The natural oxide layer that forms on aluminum surfaces serves as a protective barrier, enhancing its longevity.

3. Thermal Conductivity Aluminum exhibits high thermal conductivity, making it suitable for applications where temperature regulation is crucial. In industries such as automotive or electronics, aluminum end caps can help dissipate heat efficiently, promoting better overall performance.

4. Customization Manufacturers today can offer a variety of aluminum end caps that can be customized to meet specific requirements. Different sizes, shapes, and finishes (such as anodized or powder-coated) are available to suit diverse industrial needs. This adaptability allows engineers and designers to integrate these components seamlessly into their projects.

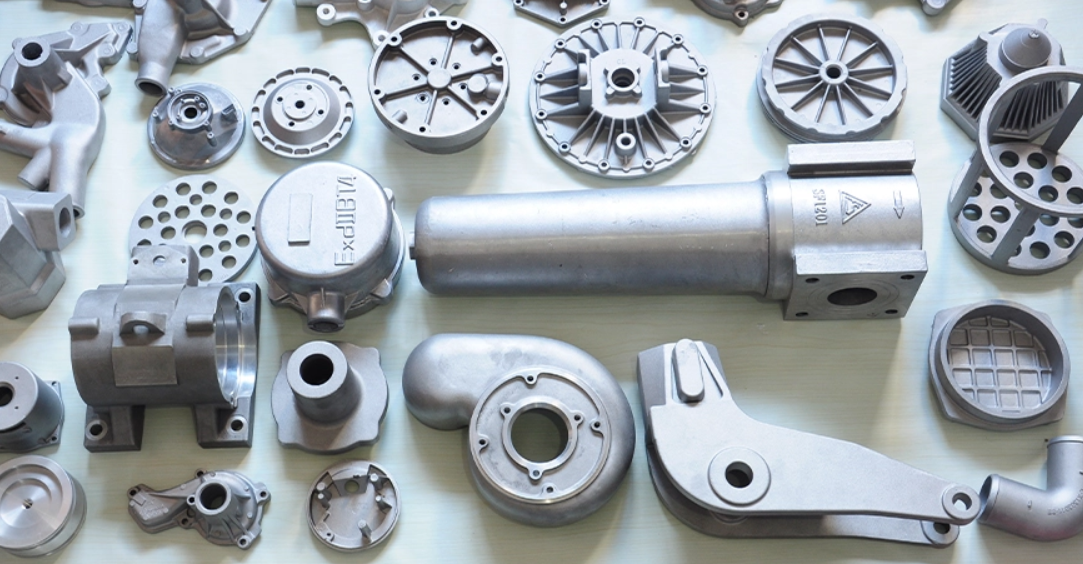

end cap aluminium

5. Cost-Effective While aluminum may not be the cheapest material available, its long-term value offers cost savings in many applications. Its durability and resistance to corrosion mean fewer replacements and repairs over time, resulting in lower maintenance costs.

Applications of Aluminum End Caps

1. Construction In the construction industry, aluminum end caps are used to cover the ends of structural tubes or pipes. They provide a polished finish, enhance safety by minimizing sharp edges, and contribute to the overall aesthetics of the building. Additionally, they help prevent moisture ingress in structural elements.

2. Automotive Industry Aluminum end caps are frequently employed in various automotive components, from exhaust systems to fuel lines. They provide essential sealing functions while keeping weight to a minimum, which is critical for improving fuel efficiency.

3. Electronics The electronics industry utilizes aluminum end caps in devices for both protection and thermal management. The lightweight and conductive nature of aluminum helps in maintaining optimal temperatures within devices, ensuring longevity and reliability.

4. Aerospace In aerospace applications, every gram counts; thus, using aluminum end caps allows for significant weight savings while maintaining structural integrity. They are utilized in various aircraft systems to protect components and maintain performance under extreme conditions.

5. Furniture and Design In furniture design, aluminum end caps are often used as finishing touches for table legs, railings, and other structures. They enhance the overall look and provide protection against wear and tear.

Conclusion

Aluminum end caps are a quintessential example of how a seemingly simple component can significantly impact various industries. With their unique properties and versatility, these end caps are not only functional but also add value through improved aesthetics and performance. As industries continue to seek materials that enhance efficiency and sustainability, aluminum end caps are poised to play a vital role in the future of manufacturing and design. Whether in construction, automotive, electronics, or aerospace, the significance of these components cannot be overstated. Investing in high-quality aluminum end caps will surely lead to enhanced product longevity and reliability across multiple applications.

-

Impeller Technology That Powers Precision in Pump SystemsNewsMay.22,2025

-

Valve Durability Begins with Quality Cast Iron ComponentsNewsMay.22,2025

-

Performance Cooling with Advanced Automobile Water Pump SolutionsNewsMay.22,2025

-

How Motor Housing and Oil Pans Shape Engine PerformanceNewsMay.22,2025

-

How Metal Castings Drive Modern Manufacturing EfficiencyNewsMay.22,2025

-

Exploring the Engineering Behind Valve Body CastingsNewsMay.22,2025