Mobile:+86-311-808-126-83

Email:info@ydcastings.com

Exploring Features and Benefits of 110mm End Caps for Your Projects

Understanding End Caps The 110mm Solution

End caps are an often overlooked yet essential component in many industries, especially in the fields of manufacturing, construction, and plumbing. This article delves into the significance of end caps, specifically focusing on the 110mm end cap, its applications, benefits, and reasons for choosing the right end cap for your specific needs.

What are End Caps?

End caps are fittings used to cover the ends of pipes, tubes, or conduits. They serve a dual purpose preventing dust and debris from entering the ends of these components and providing a finished look to the installation. By sealing off ends, end caps help maintain the integrity of the overall system, ensuring that air, liquids, or other materials do not escape from the pipeline.

The Significance of 110mm End Caps

While end caps come in various sizes to fit different types of pipes, the 110mm end cap is particularly popular in plumbing and sewage systems. This size is commonly used for a wide range of applications, from residential to commercial settings. The 110mm diameter makes it compatible with standard PVC and other types of pipes that are widely utilized for drainage and waste management.

Applications of 110mm End Caps

1. Wastewater Management In many urban areas, 110mm pipes are used in waste and sewage systems. These pipes require end caps to prevent backflow and keep the system sealed and functional. By using 110mm end caps, municipalities can ensure that wastewater is properly contained and managed.

2. Residential Plumbing Homeowners often use 110mm end caps for drainage systems, vent pipes, and other plumbing applications. They provide an effective solution to cap off unused openings, preventing odors and pests from entering homes.

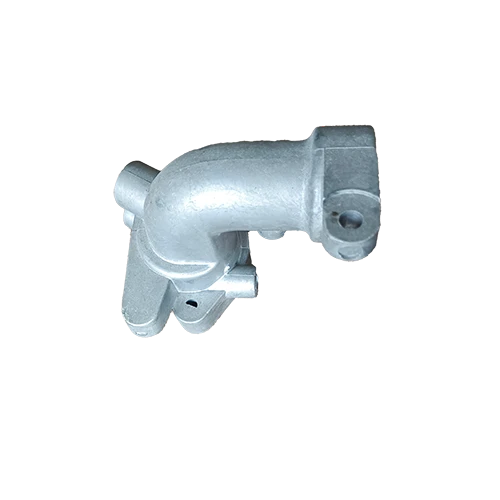

end cap 110mm

3. Construction In construction sites, end caps might be used temporarily during the building process to seal off pipes that are not currently in use. This improves safety by preventing accidental falls or injuries caused by open pipe ends.

4. Industrial Applications Factories and manufacturing plants frequently employ end caps to manage the flow of materials through piping systems. The 110mm end cap can effectively seal pipes that transport chemicals, liquids, or gases, thereby reducing the risk of leaks and spills.

Benefits of Using 110mm End Caps

1. Durability Made from materials like PVC, metal, or rubber, 110mm end caps are designed to withstand pressure, temperature changes, and environmental conditions. This makes them a reliable choice for long-term use.

2. Easy Installation Installing 110mm end caps is a straightforward process. Depending on the type of connection (push-fit, threaded, or welded), they can easily be affixed to the ends of pipes, making them a convenient option for both amateur DIYers and professional plumbers.

3. Cost-Effectiveness Given their durability and ease of installation, 110mm end caps provide a budget-friendly solution for businesses and homeowners alike. Investing in high-quality end caps can save money in the long run by preventing leaks and maintaining system efficiency.

4. Versatility The 110mm size allows for compatibility with a variety of materials and systems. Whether it's for drainage, ventilation, or fluid transport, the versatility of the 110mm end cap makes it an invaluable tool in numerous applications.

Conclusion

In conclusion, the 110mm end cap is a vital component in plumbing, construction, and industrial applications. By understanding its significance and benefits, professionals and DIY enthusiasts can make informed decisions when selecting the right end cap for their needs. Whether it is for sealing a drainage pipe in a residential setting or maintaining an industrial wastewater system, the reliable 110mm end cap is a key player in ensuring system integrity and efficiency.

-

Why Should You Invest in Superior Pump Castings for Your Equipment?NewsJun.09,2025

-

Unlock Performance Potential with Stainless Impellers and Aluminum End CapsNewsJun.09,2025

-

Revolutionize Your Machinery with Superior Cast Iron and Aluminum ComponentsNewsJun.09,2025

-

Revolutionize Fluid Dynamics with Premium Pump ComponentsNewsJun.09,2025

-

Optimizing Industrial Systems with Essential Valve ComponentsNewsJun.09,2025

-

Elevate Grid Efficiency with High-Precision Power CastingsNewsJun.09,2025