Mobile:+86-311-808-126-83

Email:info@ydcastings.com

Electric Motor Impeller Design and Efficiency Optimization Techniques for Enhanced Performance

Understanding Electric Motor Impellers A Critical Component of Modern Engineering

Electric motors have transformed the landscape of technology and engineering, serving as the driving force behind myriad applications ranging from household appliances to industrial machinery. While much focus is often placed on the motor itself, a critical component often overlooked is the impeller. This article will delve into the significance, design, and applications of electric motor impellers, shedding light on their crucial role in fluid dynamics and overall motor efficiency.

What is an Impeller?

An impeller is a rotating component of a centrifugal pump, which converts rotational energy—typically from an electric motor—to kinetic energy by moving fluid through a system. It is essentially a set of blades attached to a hub, and its primary function is to increase the velocity of the fluid, pushing it outwards to create a streamlined flow. Impellers are widely used in various applications, including water pumps, HVAC systems, and aquariums, among others.

The Importance of Impeller Design

The design of an impeller significantly influences its performance. Key factors include the shape, size, number of blades, and materials used. A well-designed impeller allows for optimal fluid motion, minimizing turbulence and maximizing efficiency. For example, an impeller with backward-curved blades may be more efficient in moving fluids at low flow rates, while one with forward-curved blades might excel in high-performance applications.

Moreover, the impeller's compatibility with the specific electric motor is crucial. Electric motors operate on a set of parameters such as speed, torque, and power output. An effective impeller must synchronize seamlessly with these factors to avoid issues such as cavitation, where vapor bubbles form and collapse in the fluid, potentially damaging the impeller and decreasing the motor's efficiency.

Material Considerations

The materials utilized for constructing electric motor impellers are also vital. Common materials include metals like stainless steel and aluminum, which offer strength and resistance to wear, but they can also be heavier. In contrast, composite materials and plastics are lighter and can provide excellent corrosion resistance, making them suitable for aggressive fluids. The choice of material often depends on the application and environmental conditions, such as temperature and chemical exposure.

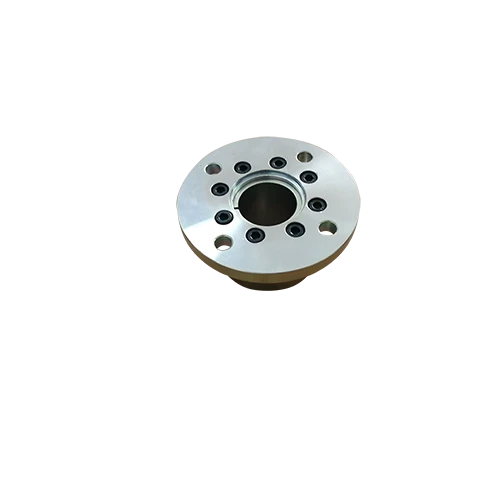

electric motor impeller

Applications of Electric Motor Impellers

Electric motor impellers find utilities in various sectors. In the automotive industry, they are used in cooling fans and fuel pumps, helping maintain optimal engine temperatures and ensuring proper fuel delivery. In residential settings, impellers are integral to water pumps that provide fresh water to households or circulate water in pools and fountains.

In industrial applications, these impellers play a pivotal role in chemical processing, wastewater treatment, and HVAC systems. Here, high-efficiency impellers can dramatically reduce energy consumption while ensuring effective fluid management.

The Future of Impeller Technology

The ongoing advancement in materials science and fluid dynamics is driving innovation in impeller design. Engineers are increasingly leveraging computer-aided design (CAD) and computational fluid dynamics (CFD) to create more efficient and robust impellers. These technologies allow for extensive testing of various design configurations, helping to optimize performance before manufacturing even begins.

Additionally, as industries continue to focus on sustainability, there is a rising demand for more energy-efficient solutions. Advancements in electric motor and impeller technology are enabling systems that consume less power while delivering higher efficiency, making them more environmentally friendly.

Conclusion

In summary, electric motor impellers are vital components that play an essential role in fluid dynamics across a range of applications. As technology progresses, the design and materials used in these impellers are set to evolve, leading to improved performance, efficiency, and sustainability. Understanding the importance of impellers not only enhances our grasp of electric motor systems but also paves the way for innovations that can significantly impact various industries in the future. By prioritizing effective impeller design and construction, we can unlock new potential in electric motors and their applications, ensuring continued progress in the field of engineering and technology.

-

Impeller Technology That Powers Precision in Pump SystemsNewsMay.22,2025

-

Valve Durability Begins with Quality Cast Iron ComponentsNewsMay.22,2025

-

Performance Cooling with Advanced Automobile Water Pump SolutionsNewsMay.22,2025

-

How Motor Housing and Oil Pans Shape Engine PerformanceNewsMay.22,2025

-

How Metal Castings Drive Modern Manufacturing EfficiencyNewsMay.22,2025

-

Exploring the Engineering Behind Valve Body CastingsNewsMay.22,2025