Mobile:+86-311-808-126-83

Email:info@ydcastings.com

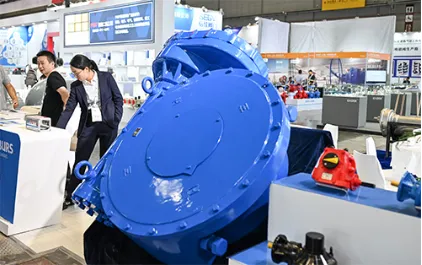

dust collector motor and impeller

The Importance of Dust Collector Motors and Impellers in Industrial Applications

In various industrial settings, managing and controlling dust particles is a significant health and safety consideration. Not only do dust particles pose inhalation risks to workers, but they can also contribute to equipment malfunction and productivity losses. This is where dust collectors—specifically their motors and impellers—become essential components in maintaining air quality and operational efficiency.

Understanding Dust Collectors

Dust collectors are systems designed to enhance the air quality in manufacturing and processing environments. They work by filtering and removing particulate matter from the air, thereby preventing dust accumulation on equipment and surfaces. A dust collector is typically made up of several key components, including a filtration system, a dust disposal system, and the heart of any collector—the motor and impeller system.

The Role of Motors in Dust Collectors

The motor drives the entire dust collection process. Motors in dust collectors are essential because they determine the efficiency and effectiveness of the unit. When selecting a motor for a dust collector, several factors must be considered, including horsepower, efficiency ratings, power source, and compatibility with the specific impeller and collector design.

A high-quality motor not only provides sufficient power to the system but also operates reliably over extended periods, which is crucial in demanding industrial environments. Motors can be electric, pneumatic, or hydraulic, but electric motors are the most common due to their efficiency and ease of use.

Impellers The Unsung Heroes

dust collector motor and impeller

While motors drive the system, impellers are critical in creating the airflow necessary for optimal dust extraction. An impeller is a rotating device that moves air into the dust collector, helping to draw dust-laden air through the filters and out of the system as clean air. The design and material of an impeller can significantly affect the performance of the dust collector.

There are several designs of impellers used in dust collectors, including centrifugal and axial types. Centrifugal impellers, for example, are commonly used because of their ability to handle large volumes of air with high efficiency. They use centrifugal force to accelerate air movement, creating a high-velocity airflow that can sweep up even the finest dust particles.

Material choice for impellers is also crucial; they are often made of metal or high-strength plastic that can withstand the harsh conditions and abrasive nature of certain dust particles. When selecting an impeller, it is essential to consider factors such as wear resistance, balance, and aerodynamics, as these elements greatly influence the system's overall performance.

Efficiency and Maintenance

The efficiency of dust collectors largely depends on the motor and impeller combination. An underperforming motor can lead to insufficient airflow and ineffective dust collection, whereas a well-matched motor-impeller system ensures optimal performance. Therefore, regular maintenance is important. This includes checking for wear and tear on both the motor and impeller, ensuring that they are clean and free of obstructions, and that all parts are functioning correctly.

In addition, monitoring energy consumption can help identify any inefficiencies that may arise during operation. Sophisticated systems that include sensors for real-time monitoring can alert operators to issues before they escalate into significant failures, leading to downtime and increased operational costs.

Conclusion

In conclusion, the synergy between dust collector motors and impellers is crucial for effective dust management in industrial settings. Understanding the roles of these components can lead to better equipment selection, improved air quality, and enhanced worker safety. By investing in high-quality motors and well-designed impellers, industries can achieve greater efficiency, lower maintenance costs, and ultimately create a healthier work environment. As dust collection technology continues to evolve, staying informed about advancements in motor and impeller design will be key for industries that prioritize air quality and worker safety.

-

Valve Body Acts as the “Heart” of Flow ControlNewsMay.19,2025

-

Understanding the Importance of ImpellersNewsMay.19,2025

-

Importance of Automobile Water PumpsNewsMay.19,2025

-

How an Engine Oil Pan Works to Keep Your Car LubricatedNewsMay.19,2025

-

Common Materials Used in Pump Impeller ManufacturingNewsMay.19,2025

-

Ball Valve Casting in Modern Pipeline SystemsNewsMay.19,2025