Mobile:+86-311-808-126-83

Email:info@ydcastings.com

Understanding the Role of Diffuser Casing in Centrifugal Pump Efficiency and Performance

The Role of Diffuser Casing in Centrifugal Pumps

Centrifugal pumps are essential components in various industrial and engineering applications, providing a reliable means of transporting fluids. A crucial aspect of these pumps is the diffuser casing, which plays a vital role in enhancing pump efficiency and performance. In this article, we will explore the significance of diffuser casings in centrifugal pumps, their design considerations, and their impact on overall pump functionality.

Understanding the Basics

Before delving deeper into diffuser casings, it is essential to understand the operational principles of centrifugal pumps. These pumps convert mechanical energy from a rotating impeller into hydraulic energy, producing fluid flow. The impeller's rotation creates a centrifugal force, propelling the fluid outward and increasing its velocity. However, to convert this velocity into pressure, the design of the pump must incorporate components such as the diffuser casing.

What is a Diffuser Casing?

A diffuser casing surrounds the pump’s impeller. It serves to collect the high-velocity fluid exiting the impeller and gradually convert its kinetic energy into pressure energy through a process known as diffusion. The casing typically features a series of vanes that direct the flow and guide it towards the discharge port, where it exits the pump.

Design Considerations

Designing an effective diffuser casing involves several critical considerations

1. Hydraulic Efficiency The geometry of the diffuser casing affects the overall hydraulic efficiency of the pump. An optimal design minimizes turbulence and flow separation, allowing for smoother fluid transitions. The layout, including the angle and shape of the vanes, must be carefully calibrated to achieve maximum efficiency.

2. Pressure Recovery One of the primary functions of the diffuser is to facilitate pressure recovery. As fluid velocity decreases in the diffuser, the pressure should increase. An inadequately designed diffuser may fail to achieve the necessary pressure recovery, leading to reduced pump performance.

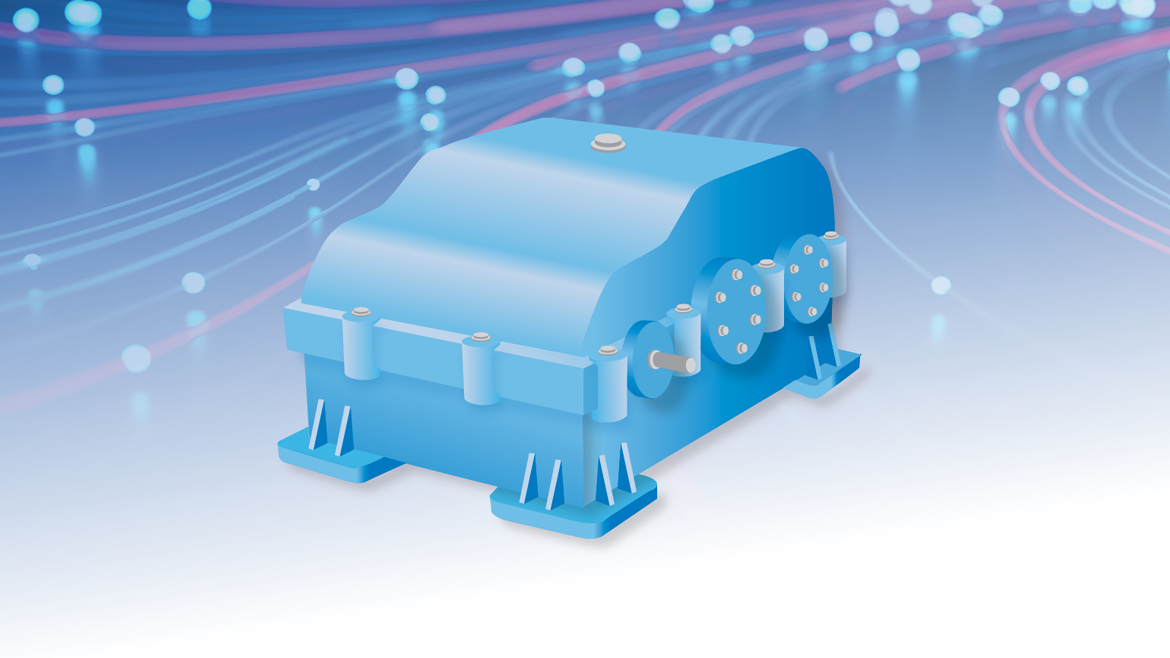

diffuser casing in centrifugal pump

3. Flow Characteristics Understanding the expected flow characteristics is crucial when designing a diffuser casing. Factors such as flow rate, viscosity, and the nature of the fluid being pumped must be analyzed to ensure the casing can handle the operational parameters without causing cavitation or other undesirable flow phenomena.

4. Material Selection The materials used in constructing the diffuser casing must withstand the operational conditions, including pressure, temperature, and the properties of the fluid. Stainless steel, composite materials, and various alloys may be used to prevent corrosion and wear.

Benefits of an Efficient Diffuser Casing

An efficient diffuser casing contributes significantly to the overall performance of a centrifugal pump. Here are some key benefits

- Increased Efficiency A well-designed diffuser can significantly boost the pump's efficiency by optimizing the conversion of kinetic energy into pressure energy, leading to lower operational costs and energy savings.

- Reduced Wear and Tear By minimizing turbulence and ensuring smoother flow, an effective diffuser casing can reduce wear on the impeller and other components, extending the lifespan of the pump.

- Enhanced Performance Improved pressure recovery and flow characteristics lead to better overall pump performance, making it suitable for a wide range of applications, from water treatment plants to chemical processing facilities.

- Lower Maintenance Requirements Efficiently designed diffuser casings reduce the likelihood of pressure fluctuations and cavitation, which can lead to mechanical failures. Consequently, this results in lower maintenance costs and less downtime for repairs.

Conclusion

The role of diffuser casings in centrifugal pumps cannot be overstated. They are integral to enhancing pump efficiency, ensuring reliable performance, and extending the operational lifespan of the equipment. As industries continue to demand higher performance and efficiency from their pumping systems, the importance of carefully engineered diffuser designs will only grow. Engineers and designers must prioritize these elements to create centrifugal pumps that meet the rigorous demands of modern applications, ensuring optimal functionality and cost-effectiveness in fluid transport solutions. As technology in fluid dynamics evolves, the future of diffuser casings will undoubtedly continue to innovate, leading to even more efficient and effective pumping systems.

-

Why Should You Invest in Superior Pump Castings for Your Equipment?NewsJun.09,2025

-

Unlock Performance Potential with Stainless Impellers and Aluminum End CapsNewsJun.09,2025

-

Revolutionize Your Machinery with Superior Cast Iron and Aluminum ComponentsNewsJun.09,2025

-

Revolutionize Fluid Dynamics with Premium Pump ComponentsNewsJun.09,2025

-

Optimizing Industrial Systems with Essential Valve ComponentsNewsJun.09,2025

-

Elevate Grid Efficiency with High-Precision Power CastingsNewsJun.09,2025