Mobile:+86-311-808-126-83

Email:info@ydcastings.com

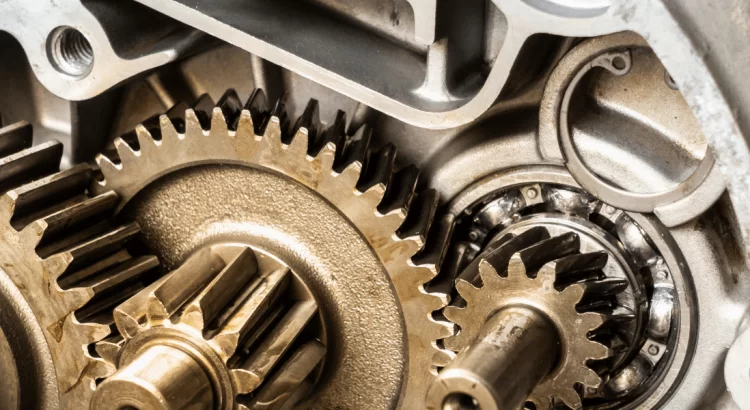

die cast part

Die Cast Part Manufacturing An Overview

Die casting is a manufacturing process that is widely utilized in the production of metal parts. This method involves forcing molten metal into a mold cavity under high pressure, resulting in high-precision components with excellent surface finishes. Among the diverse sectors benefiting from die casting are the automotive, aerospace, electronics, and consumer goods industries. In this article, we will explore the various aspects of die cast part manufacturing, including its advantages, materials used, the process itself, and its applications.

Advantages of Die Casting

One of the primary advantages of die casting is its ability to produce complex shapes with high dimensional accuracy. The precision achieved in die casting can be as tight as ±0.1mm, which is crucial for components that need to fit together seamlessly. Additionally, die casting allows for thin walls and intricate details, enabling manufacturers to create lightweight parts without sacrificing strength.

Another significant benefit is the efficiency of the process. Once the die is created, it can be used repeatedly to produce large volumes of parts at a relatively low cost per unit. This scalability makes die casting an ideal choice for mass production, which is particularly beneficial for industries like automotive and electronics where high throughput is essential.

The surface finish of die cast parts is another notable advantage. The process generally results in a smooth surface, reducing or even eliminating the need for additional finishing operations. This not only saves time but also lowers production costs. Furthermore, die casting allows for the incorporation of features such as ribs, bosses, and slots directly into the part design, which further enhances its functionality without additional manufacturing steps.

Materials Used in Die Casting

Aluminum, zinc, and magnesium are the most common metals used in die casting, each offering distinct characteristics that cater to specific applications. Aluminum die casting is particularly notable for its lightweight and corrosion-resistant properties, making it a preferred choice for the automotive industry where fuel efficiency is paramount. Zinc die casting, on the other hand, is celebrated for its excellent dimensional stability and impact resistance, which is ideal for producing complex components like connectors and brackets. Magnesium die casting, while less common, is used for parts where weight reduction is crucial, such as in aerospace applications.

die cast part

Beyond these primary materials, die casting can also accommodate alloys, which can further enhance the mechanical properties of the final product. The selection of the appropriate material is vital to ensure that the die cast part meets the specific performance requirements of its intended application.

The Die Casting Process

The die casting process consists of several key steps. Initially, a die is designed and manufactured. The die itself is a two-part mold, typically made from high-strength steel, which allows for numerous cycles of production. The design of the die is critical, as it must account for the shrinkage of the metal as it cools and solidifies.

Once the die is ready, the process begins with melting the metal in a furnace. The molten metal is then injected into the die at high pressure using a piston or plunger mechanism. The high pressure ensures that the molten metal fills the intricate cavities of the die, capturing every detail.

After the metal has solidified, the die is opened, and the part is ejected. This rapid cycle can take just a few seconds, allowing for significant production volumes. The finished parts may undergo secondary operations such as trimming, machining, or surface finishing depending on the specifications required.

Applications of Die Cast Parts

Die cast parts are ubiquitous across various industries. In the automotive sector, components such as engine blocks, transmission housings, and decorative trim pieces are commonly produced using die casting. The aerospace industry benefits from lightweight structural elements that can withstand extreme conditions. In consumer electronics, die casting is employed for intricate housings and frames that provide both protection and aesthetic appeal.

In conclusion, die casting is an efficient, versatile, and cost-effective manufacturing method for producing high-quality metal parts. Its advantages, including precision, production efficiency, and superior surface finishes, make it a popular choice across many industries. As technology continues to evolve, the die casting process is expected to become even more efficient, allowing for the production of even more complex and delicate parts.

-

Why Should You Invest in Superior Pump Castings for Your Equipment?NewsJun.09,2025

-

Unlock Performance Potential with Stainless Impellers and Aluminum End CapsNewsJun.09,2025

-

Revolutionize Your Machinery with Superior Cast Iron and Aluminum ComponentsNewsJun.09,2025

-

Revolutionize Fluid Dynamics with Premium Pump ComponentsNewsJun.09,2025

-

Optimizing Industrial Systems with Essential Valve ComponentsNewsJun.09,2025

-

Elevate Grid Efficiency with High-Precision Power CastingsNewsJun.09,2025