Mobile:+86-311-808-126-83

Email:info@ydcastings.com

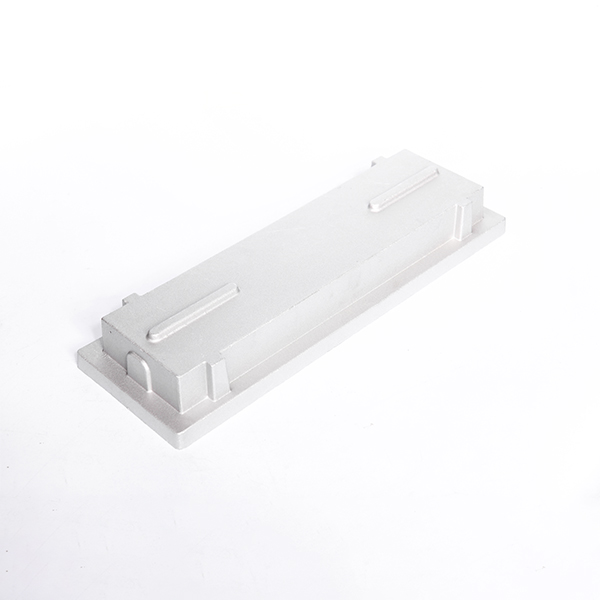

custom casting molds

Custom Casting Molds Revolutionizing the Manufacturing Process

In the world of manufacturing, precision, efficiency, and creativity are paramount. Custom casting molds have emerged as an indispensable tool in achieving these goals, allowing businesses to produce intricate designs and high-quality products at scale. This article explores the significance of custom casting molds, their benefits, and the various applications across different industries.

What are Custom Casting Molds?

Custom casting molds are specially designed molds used to shape materials such as metal, plastic, or resin into specific forms. The concept of casting involves pouring a liquid material into a mold, where it solidifies and takes the shape of the mold. Unlike standard molds, custom molds are tailored to meet the unique requirements of a particular project, accommodating complex geometries and specific material characteristics.

The Benefits of Using Custom Casting Molds

1. Precision and Accuracy One of the key advantages of custom casting molds is their ability to produce highly accurate and precise parts. With advanced design software and manufacturing techniques, molds can be crafted to exact specifications, ensuring that the final products meet stringent quality standards.

2. Cost-Effectiveness While the initial investment in custom molds may be higher than off-the-shelf options, they can lead to significant cost savings in the long run. Custom molds are designed to maximize material usage and minimize waste, making the production process more economical over time.

3. Enhanced Design Flexibility Custom casting molds provide manufacturers with the flexibility to create unique designs that would be difficult or impossible to achieve with standard molds. This adaptability opens the door to innovation, enabling businesses to differentiate their products in competitive markets.

4. Shorter Lead Times By investing in custom molds, manufacturers can streamline their production processes. With precise molds that fit their specific needs, companies can reduce setup time and lead times for new product launches, allowing them to respond more quickly to market demands.

custom casting molds

5. Improved Surface Finish Custom molds can be engineered to ensure a superior surface finish on the final products. This is particularly crucial in industries where aesthetics and surface quality matter, such as consumer electronics and automotive parts.

Applications Across Industries

The versatility of custom casting molds means they find applications in a wide range of industries

- Automotive In the automotive sector, custom molds are used to produce various components, including engine parts, body panels, and interior fittings. The demand for lightweight and high-strength materials has made custom casting increasingly essential.

- Aerospace The aerospace industry relies on custom molds for critical components that must adhere to stringent safety and performance standards. Precision casting ensures that parts are both lightweight and durable, vital for aircraft performance.

- Consumer Goods From household items to high-end electronics, custom molds play a significant role in the production of consumer goods. Manufacturers can create unique designs that appeal to consumers while maintaining functionality.

- Art and Design Artists and designers often utilize custom casting molds to bring their visions to life. Whether it's sculptures, decorative pieces, or functional art, custom molds allow for creativity to flourish.

Conclusion

Custom casting molds are revolutionizing the manufacturing landscape by providing unprecedented precision, cost savings, and design flexibility. As industries continue to evolve and demand more innovative products, the role of custom casting molds will only become more critical. By investing in custom molds, businesses can not only enhance their production capabilities but also pave the way for future innovations in design and manufacturing. Whether you're in automotive, aerospace, or consumer goods, embracing custom casting molds could be the key to staying competitive in today’s fast-paced market.

-

Why Should You Invest in Superior Pump Castings for Your Equipment?NewsJun.09,2025

-

Unlock Performance Potential with Stainless Impellers and Aluminum End CapsNewsJun.09,2025

-

Revolutionize Your Machinery with Superior Cast Iron and Aluminum ComponentsNewsJun.09,2025

-

Revolutionize Fluid Dynamics with Premium Pump ComponentsNewsJun.09,2025

-

Optimizing Industrial Systems with Essential Valve ComponentsNewsJun.09,2025

-

Elevate Grid Efficiency with High-Precision Power CastingsNewsJun.09,2025