Mobile:+86-311-808-126-83

Email:info@ydcastings.com

Exploring Compression Fitting End Caps for Enhanced Pipe Connections and Performance

Compression Fitting End Caps A Comprehensive Overview

Compression fitting end caps are essential components in various industries, particularly in plumbing, HVAC, and general fluid handling systems. These specialized caps serve multiple purposes, offering not just a means to seal pipes, but also contributing to the overall efficiency and safety of fluid transport systems. This article delves into the fundamentals of compression fitting end caps, their applications, materials, and advantages.

Understanding Compression Fitting End Caps

Compression fittings are a type of mechanical fitting used to join two pipes or tubes together. Unlike welded or soldered joints, compression fittings do not require heat, making them a popular choice for many applications. An end cap, in this context, is designed to close the end of a pipe or tube, providing a secure seal and preventing fluid leakage.

Typically, compression fittings consist of three components the nut, the ring (or ferrule), and the body. When assembled, the nut screws down onto the body, compressing the ring against the pipe or tube, which creates a leak-proof seal. End caps can be found in various sizes and configurations to accommodate different pipe diameters and types.

Applications of Compression Fitting End Caps

Compression fitting end caps have a wide range of applications across different fields. In plumbing, they are commonly used to terminate or close off water supply lines, whether in residential or industrial settings. In HVAC systems, they can be utilized to seal off unused ends of ductwork or piping, thereby maintaining system efficiency.

In the chemical processing industry, these caps play a vital role in safely sealing pipes that transport hazardous materials. The ability of compression fittings to create a tight seal helps prevent leaks, which could pose serious safety hazards. Additionally, end caps are often employed in hydraulic systems to ensure that hydraulic fluids do not escape, thus maintaining system pressure and functionality.

Materials Used in Compression Fitting End Caps

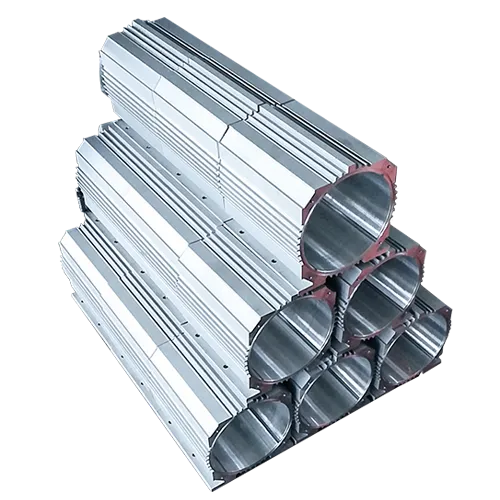

compression fitting end cap

The choice of material for compression fitting end caps is crucial, as it influences the cap's durability, compatibility with various fluids, and overall performance. Common materials include

1. Brass Known for its excellent corrosion resistance and strength, brass is a popular choice for water and gas applications. 2. Stainless Steel Favored in high-pressure and corrosive environments, stainless steel end caps are robust and maintain integrity under extreme conditions. 3. Plastic Often used for lightweight applications, plastic caps are resistant to corrosion and can be ideal for certain chemical applications. 4. Copper Traditionally used in plumbing, copper compression fittings offer good thermal conductivity and resistance to high temperatures.

Advantages of Compression Fitting End Caps

The advantages of using compression fitting end caps are numerous. Firstly, their installation is relatively straightforward and does not require specialized tools. This ease of installation can lead to reduced labor costs and shorter project timelines.

Additionally, compression fittings are reusable, which can be a significant factor in maintenance. If repairs or modifications are necessary, these fittings can be disassembled and reassembled without damage, making them economical in the long run.

Another significant benefit is their leak-proof design. Compression fittings, when installed correctly, provide a reliable seal that minimizes the risk of leakage, crucial for systems handling water, gas, and chemicals.

Lastly, compression fitting end caps are versatile and can be used in a variety of applications and with different types of pipes, making them a flexible option for engineers and technicians.

Conclusion

In summary, compression fitting end caps play a pivotal role in ensuring the efficiency, safety, and reliability of fluid transport systems across various industries. Their straightforward installation, reusable nature, and ability to create leak-proof seals make them invaluable assets in both residential and industrial applications. As industries continue to evolve and prioritize efficiency, the significance of high-quality compression fitting end caps will only grow, cementing their status as essential components in modern infrastructure.

-

Why Should You Invest in Superior Pump Castings for Your Equipment?NewsJun.09,2025

-

Unlock Performance Potential with Stainless Impellers and Aluminum End CapsNewsJun.09,2025

-

Revolutionize Your Machinery with Superior Cast Iron and Aluminum ComponentsNewsJun.09,2025

-

Revolutionize Fluid Dynamics with Premium Pump ComponentsNewsJun.09,2025

-

Optimizing Industrial Systems with Essential Valve ComponentsNewsJun.09,2025

-

Elevate Grid Efficiency with High-Precision Power CastingsNewsJun.09,2025