Mobile:+86-311-808-126-83

Email:info@ydcastings.com

Gen . 17, 2025 04:50

Back to list

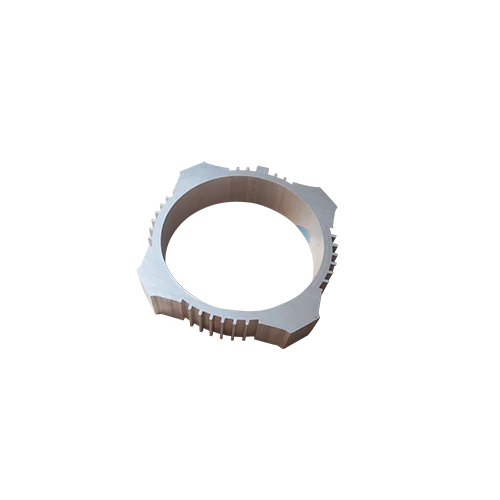

Pump Body

Compression cap ends are pivotal components in a multitude of industrial applications, yet many overlook their significance beyond their basic functions. For those seeking to optimize systems where these components are employed, understanding their nuances is key to maximizing performance, safety, and efficiency.

Understanding the installation nuances of compression cap ends further solidifies their trustworthiness in any application. Proper installation involves aligning the piping accurately, ensuring that the cap end is clean and undamaged, and that it is tightened according to specified torque requirements. Over-tightening or misalignment can lead to problems such as leaks or fractures, highlighting the importance of expertise during both selection and installation stages. Employing experienced technicians familiar with the specific requirements of compression fittings can drastically reduce failure rates and maintenance costs over time. Consumers seeking to integrate these components should consider technical support services offered by suppliers. This not only aids in the correct selection of components but also provides invaluable insights into future scalability and system upgrades. Suppliers who offer comprehensive technical resources and customer support enable decision-makers to make informed choices, further establishing the operational trustworthiness necessary in high-stakes environments. In summary, while compression cap ends may seem like minor components within larger systems, their impact is substantial. These components encapsulate the essence of precision engineering and material science, making them indispensable to industries where airtight seals are non-negotiable. By emphasizing experience, expertise, authoritativeness, and trustworthiness in their selection and application, stakeholders can harness their full potential, ensuring both performance efficacy and safety.

Understanding the installation nuances of compression cap ends further solidifies their trustworthiness in any application. Proper installation involves aligning the piping accurately, ensuring that the cap end is clean and undamaged, and that it is tightened according to specified torque requirements. Over-tightening or misalignment can lead to problems such as leaks or fractures, highlighting the importance of expertise during both selection and installation stages. Employing experienced technicians familiar with the specific requirements of compression fittings can drastically reduce failure rates and maintenance costs over time. Consumers seeking to integrate these components should consider technical support services offered by suppliers. This not only aids in the correct selection of components but also provides invaluable insights into future scalability and system upgrades. Suppliers who offer comprehensive technical resources and customer support enable decision-makers to make informed choices, further establishing the operational trustworthiness necessary in high-stakes environments. In summary, while compression cap ends may seem like minor components within larger systems, their impact is substantial. These components encapsulate the essence of precision engineering and material science, making them indispensable to industries where airtight seals are non-negotiable. By emphasizing experience, expertise, authoritativeness, and trustworthiness in their selection and application, stakeholders can harness their full potential, ensuring both performance efficacy and safety.

Next:

Latest news

-

Why Should You Invest in Superior Pump Castings for Your Equipment?NewsJun.09,2025

-

Unlock Performance Potential with Stainless Impellers and Aluminum End CapsNewsJun.09,2025

-

Revolutionize Your Machinery with Superior Cast Iron and Aluminum ComponentsNewsJun.09,2025

-

Revolutionize Fluid Dynamics with Premium Pump ComponentsNewsJun.09,2025

-

Optimizing Industrial Systems with Essential Valve ComponentsNewsJun.09,2025

-

Elevate Grid Efficiency with High-Precision Power CastingsNewsJun.09,2025

Related PRODUCTS