Mobile:+86-311-808-126-83

Email:info@ydcastings.com

coin molds for metal casting

Coin Molds for Metal Casting An Overview

Metal casting is an age-old technique that has played a crucial role in the production of various metal objects—coins being one of its most significant applications. The process of creating coins involves the use of specialized molds designed to accurately replicate intricate designs and ensure uniformity in size and weight. This article provides an overview of coin molds for metal casting, their types, benefits, and considerations for their use.

Coin Molds for Metal Casting An Overview

There are mainly two types of molds used in coin casting sand molds and metal molds. Sand casting is often preferred for lower volume production due to its lower costs and ease of use. In this process, a pattern of the coin is made from a rigid material, and sand is compacted around it to form a mold. After the pattern is removed, molten metal is poured into the cavity to create the coin. While this method is versatile, the detail level may be limited compared to metal molds.

coin molds for metal casting

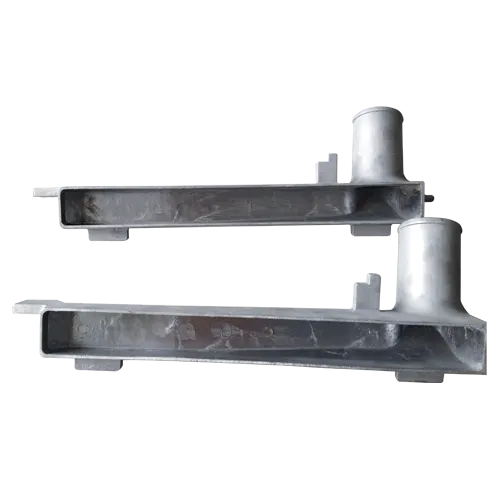

Metal molds, on the other hand, are used in high-volume production because they allow for greater precision and surface finish. These molds are machined from high-strength alloys, and their design can incorporate cooling systems to decrease the solidification time of the molten metal. This results in a more efficient casting process, enabling the mass production of coins with consistent quality.

The advantages of high-quality coin molds extend beyond just producing coins. They play a crucial role in the overall efficiency and cost-effectiveness of metal casting operations. Well-designed molds can reduce waste material, minimize the likelihood of defects, and speed up production times. Furthermore, as minting technology evolves, the integration of advanced molding techniques, such as 3D printing, is beginning to influence how molds are created, allowing for even greater customization and design complexity.

In conclusion, coin molds are an essential component of metal casting, pivotal for creating the currency that facilitates trade around the world. Understanding the types of molds, their material properties, and the casting process can significantly enhance the efficiency and quality of coin production, ensuring that traditional and modern coins continue to meet the demands of society.