Mobile:+86-311-808-126-83

Email:info@ydcastings.com

Exploring the Applications and Benefits of CF8M Casting in Modern Industries

The Significance of CF8M Casting in Modern Engineering

CF8M casting, also referred to in many industries as stainless steel casting, plays a pivotal role in various engineering applications today. This type of casting is specifically made from austenitic stainless steel, which is known for its excellent corrosion resistance, durability, and high-temperature strength. As such, CF8M casting is utilized in a myriad of industries, ranging from chemical processing to oil and gas, and even water treatment.

Understanding CF8M Casting

CF8M typically consists of 18% chromium, 8% nickel, and 2% molybdenum, giving it its unique properties. The chemical composition not only enhances the mechanical strength of the material but also improves its resistance to pitting and crevice corrosion, which are common issues in corrosive environments. This makes CF8M a preferred material for valves, pumps, and other components that are used in environments where they are exposed to harsh chemicals or extreme temperatures.

Applications of CF8M Casting

1. Chemical Processing CF8M is widely used in the fabrication of various equipment for the chemical industry. It is often employed in pumps, valves, and fittings, where its resistance to aggressive chemicals ensures longevity and reliability in operations. The ability to withstand high pressures and temperatures makes it invaluable for processes involving corrosive substances.

2. Oil and Gas In the oil and gas sector, CF8M castings are essential for manufacturing components that function in challenging environments. Subsea valves, control systems, and piping made from CF8M are commonly utilized due to their durability and resistance to saltwater corrosion and extreme pressure conditions.

3. Water Treatment Water treatment facilities frequently utilize CF8M materials for pumps and valves that manage the processing and distribution of water. The material’s properties help to minimize the risk of contamination and ensure that treated water maintains its quality.

4. Food and Beverage Industry The food and beverage sector also benefits from CF8M casting. Stainless steel's non-reactive nature ensures that food products remain uncontaminated, and its ease of cleaning meets stringent hygiene standards required in food processing plants.

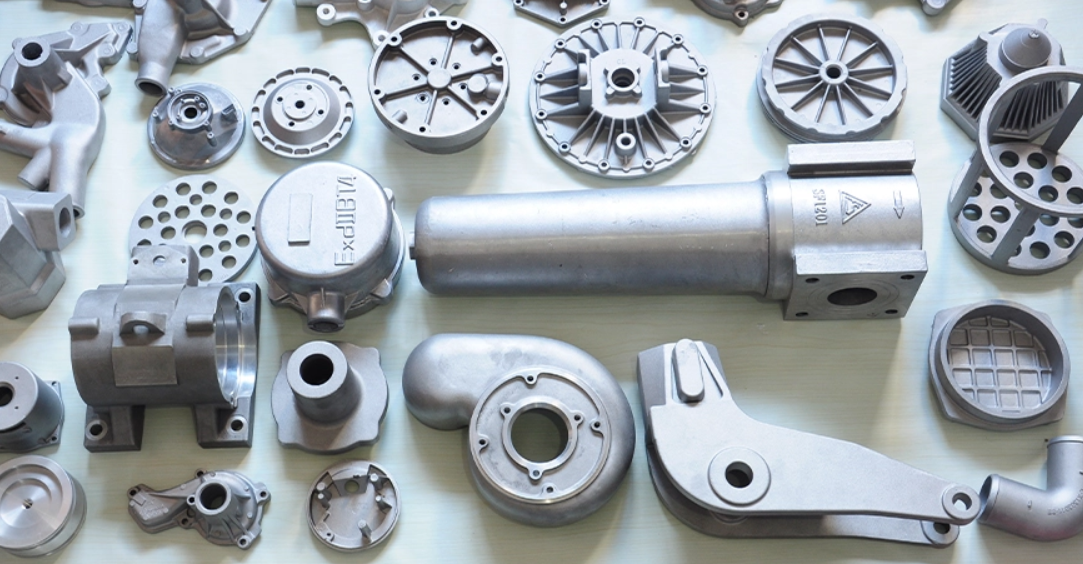

cf8m casting

Advantages of CF8M Casting

The advantages of CF8M casting extend beyond its chemical composition. One of the main benefits is its excellent machinability, allowing for intricate designs and precision components. Manufacturers can achieve tight tolerances, which is critical in high-performance applications where fitting and assembly must be flawless.

Another important aspect is the material’s capability to withstand a wide range of temperatures, making it suitable for both cryogenic and high-heat applications. Its stability under thermal cycling reduces the likelihood of failure in critical infrastructure, ensuring safety and efficiency.

Moreover, the sustainability of CF8M stainless steel casting is noteworthy. Stainless steel is 100% recyclable, which significantly reduces the environmental footprint of manufacturing processes. This aligns with the growing emphasis on sustainability within industries, encouraging manufacturers to adopt more environmentally friendly practices.

Challenges in CF8M Casting

Despite its many advantages, there are challenges associated with CF8M casting. The production process can be complex and require significant energy input, leading to higher costs compared to other casting materials. Additionally, careful control over the parameters of casting is essential, as deviations can lead to defects such as porosity or dimensional inaccuracies.

Conclusion

CF8M casting represents a crucial element in modern engineering and industrial applications. Its excellent corrosion resistance, strength, and versatility make it a go-to material for a variety of industries, ensuring reliability and performance in demanding environments. As technology advances and industries evolve, the role of CF8M casting is expected to expand, reinforcing its significance in engineering solutions for the future. As such, continued investment in research and development will be essential to overcome challenges and optimize the use of CF8M castings in innovative new applications.

-

Why Should You Invest in Superior Pump Castings for Your Equipment?NewsJun.09,2025

-

Unlock Performance Potential with Stainless Impellers and Aluminum End CapsNewsJun.09,2025

-

Revolutionize Your Machinery with Superior Cast Iron and Aluminum ComponentsNewsJun.09,2025

-

Revolutionize Fluid Dynamics with Premium Pump ComponentsNewsJun.09,2025

-

Optimizing Industrial Systems with Essential Valve ComponentsNewsJun.09,2025

-

Elevate Grid Efficiency with High-Precision Power CastingsNewsJun.09,2025