Mobile:+86-311-808-126-83

Email:info@ydcastings.com

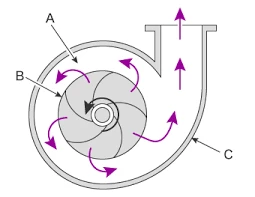

Design and Functionality of Centrifugal Pump Volute Casing in Fluid Dynamics Applications

Understanding Centrifugal Pump Volute Casing

Centrifugal pumps are essential components in various industries, playing a crucial role in fluid transportation, including water supply, wastewater treatment, and chemical processing. At the heart of a centrifugal pump's design is the volute casing, which significantly influences its performance and efficiency. This article explores the importance of volute casing, its design characteristics, and its impact on pump functionality.

Understanding Centrifugal Pump Volute Casing

One of the critical design considerations for volute casings is their geometry. The cross-sectional area and curvature of the volute must be optimized to ensure efficient fluid flow and minimize hydraulic losses. An ideal volute casing will feature a gradual expansion that helps in maintaining a steady flow, preventing turbulence, and reducing the risk of cavitation. Proper design also contributes to the overall stability of the pump operation, promoting longevity and reliability.

centrifugal pump volute casing

Furthermore, the material selection for volute casings is vital in environments where pumps handle abrasive or corrosive fluids. Common materials include cast iron, stainless steel, and various alloys, chosen based on the specific applications and fluid characteristics. This ensures that the volute casing can withstand wear and tear while maintaining structural integrity.

The effectiveness of a centrifugal pump is significantly influenced by the volute casing design, as it impacts not only the hydraulic performance but also energy consumption. A well-designed volute can enhance the efficiency of the pump, reducing operational costs over time. In contrast, poor volute designs can lead to excessive vibrations, noise, and premature wear, ultimately resulting in higher maintenance costs and downtime.

In conclusion, the volute casing is a fundamental component of centrifugal pumps that contributes to their efficiency and effectiveness. By understanding its design and functionality, engineers can create pumps that not only perform optimally but also meet the rigorous demands of various industrial applications. Investing in quality volute casings ensures reliable pump performance and operational sustainability in an ever-evolving industry landscape.

-

Why Should You Invest in Superior Pump Castings for Your Equipment?NewsJun.09,2025

-

Unlock Performance Potential with Stainless Impellers and Aluminum End CapsNewsJun.09,2025

-

Revolutionize Your Machinery with Superior Cast Iron and Aluminum ComponentsNewsJun.09,2025

-

Revolutionize Fluid Dynamics with Premium Pump ComponentsNewsJun.09,2025

-

Optimizing Industrial Systems with Essential Valve ComponentsNewsJun.09,2025

-

Elevate Grid Efficiency with High-Precision Power CastingsNewsJun.09,2025