Mobile:+86-311-808-126-83

Email:info@ydcastings.com

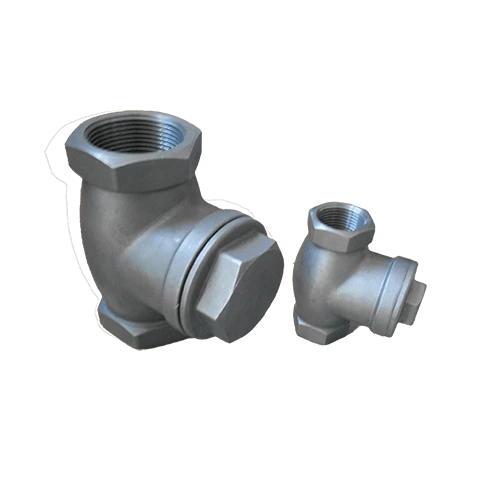

cast iron pump casing

Understanding Cast Iron Pump Casings Strength and Versatility

In the world of industrial machinery and fluid transportation, the pump is a critical component that ensures efficient movement of liquids. Among the various materials used for pump casings, cast iron stands out due to its unique combination of strength, durability, and versatility. This article explores the characteristics, advantages, and applications of cast iron pump casings, highlighting why they are often the material of choice in various industrial sectors.

What is Cast Iron?

Cast iron is an iron-carbon alloy typically containing 2-4% carbon along with silicon, manganese, and other elements. The casting process involves melting the iron and pouring it into a mold, allowing it to solidify into a desired shape. The result is a material known for its excellent casting properties, which makes it ideal for creating complex geometries often required for pump casings.

Advantages of Cast Iron Pump Casings

1. Strength and Durability One of the most significant advantages of cast iron is its inherent strength. Cast iron pump casings can withstand high pressure and heavy loads, making them suitable for demanding applications. This durability translates into a longer lifespan, thereby reducing the frequency of replacements and maintenance costs.

2. Corrosion Resistance Cast iron exhibits good corrosion resistance, particularly when treated with coatings or finishes. This property is particularly beneficial in environments where pumps are exposed to moisture and other corrosive substances. The ability to resist oxidation over time contributes to the integrity and reliability of cast iron pump casings.

3. Versatility Cast iron is a versatile material, making it suitable for a wide range of applications, from wastewater treatment to agricultural irrigation and industrial processes. Its adaptability enables manufacturers to produce pump casings in various sizes and shapes, catering to different fluid dynamics and requirements.

4. Ease of Machining While cast iron is known for its strength, it is also relatively easy to machine compared to more modern materials, such as stainless steel. This machinability allows for precise manufacturing of pump components and facilitates modifications if design changes are necessary.

cast iron pump casing

5. Cost-Effectiveness Compared to other materials such as bronze or stainless steel, cast iron tends to be more cost-effective. This affordability is crucial for large-scale applications where many pumps are required, as it helps keep project budgets in check without compromising on quality.

Applications of Cast Iron Pump Casings

Cast iron pump casings are found in various sectors, including

- Municipal Water Systems Many cities rely on cast iron pump casings for their water supply systems due to their ability to handle large volumes of water under pressure.

- Wastewater Treatment Plants In these facilities, cast iron pumps play a vital role in moving sewage and treatment chemicals, where durability and corrosion resistance are paramount.

- Industrial Processes Industries ranging from chemical manufacturing to food processing use cast iron pump casings to handle various liquids and slurries, owing to their robustness and reliability.

- Agriculture Farmers utilize cast iron pumps for irrigation, ensuring that crops receive adequate water supply in a cost-effective manner.

Conclusion

Cast iron pump casings remain a popular choice in many industrial and municipal applications due to their strength, durability, and overall performance. As industries evolve and technology advances, cast iron continues to prove its worth as a reliable and effective material for pump manufacturing. By understanding the advantages and applications of cast iron pump casings, engineers and industry professionals can make informed decisions that enhance efficiency and productivity within their operations. In an age where reliability and cost-efficiency are crucial, cast iron remains a foundational element in pump design and manufacturing, ensuring the seamless operation of fluid transport systems across various sectors.

-

Why Should You Invest in Superior Pump Castings for Your Equipment?NewsJun.09,2025

-

Unlock Performance Potential with Stainless Impellers and Aluminum End CapsNewsJun.09,2025

-

Revolutionize Your Machinery with Superior Cast Iron and Aluminum ComponentsNewsJun.09,2025

-

Revolutionize Fluid Dynamics with Premium Pump ComponentsNewsJun.09,2025

-

Optimizing Industrial Systems with Essential Valve ComponentsNewsJun.09,2025

-

Elevate Grid Efficiency with High-Precision Power CastingsNewsJun.09,2025