Mobile:+86-311-808-126-83

Email:info@ydcastings.com

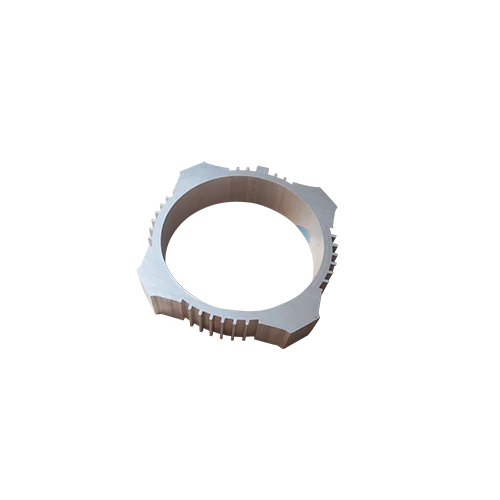

cast iron bearing

The Significance and Applications of Cast Iron Bearing

Cast iron bearings have been a cornerstone in the field of engineering and mechanical design for many years. Known for their durability, resistance to wear, and ability to sustain heavy loads, cast iron bearings are widely used in various applications, including automotive, aerospace, agricultural machinery, and industrial equipment. This article explores the properties, advantages, applications, and manufacturing processes of cast iron bearings.

Properties of Cast Iron Bearings

Cast iron is an alloy of iron that contains carbon and silicon. The unique properties of cast iron make it an ideal material for bearings. One of its most notable characteristics is its excellent wear resistance, which is achieved through the formation of a graphite microstructure. This graphite not only acts as a lubricant but also helps in dissipating heat generated during operation, which further prolongs the life of the bearing.

In addition to wear resistance, cast iron bearings exhibit high load-bearing capacity. They can withstand significant loads without deforming, making them suitable for applications where heavy machinery is involved. Moreover, cast iron is relatively inexpensive compared to other bearing materials like steel or bronze, making it a cost-effective choice for various industrial applications.

Advantages of Cast Iron Bearings

The advantages of cast iron bearings are numerous. One of the primary benefits is their self-lubricating properties. The graphite within the cast iron provides a low-friction surface that minimizes wear during operation, reducing the need for additional lubrication and maintenance. This feature is particularly valuable in environments that are difficult to access for regular maintenance.

Cast iron bearings also offer excellent shock absorption properties. This characteristic is crucial in applications that experience sudden impacts or vibrations, as it helps to protect the machinery and extend its lifespan. Additionally, cast iron is resistant to corrosion and oxidation, which makes it suitable for use in harsh environments, including those exposed to moisture and chemicals.

cast iron bearing

Applications of Cast Iron Bearings

The applications of cast iron bearings are diverse and essential to many industries. In the automotive sector, they are used in components such as crankshafts, camshafts, and wheel hubs. The durability and cost-effectiveness of cast iron bearings help in reducing overall vehicle maintenance costs while ensuring reliable performance.

In the aerospace industry, cast iron bearings are utilized in landing gear mechanisms and other critical components. Their ability to withstand high loads and harsh conditions makes them suitable for aircraft applications where reliability is paramount. Similarly, in agriculture, cast iron bearings can be found in tractors and harvesting equipment, where they endure harsh environments and heavy workloads.

Industrial machinery also benefits significantly from cast iron bearings. They are commonly used in conveyor systems, pumps, and heavy-duty machinery, where their wear resistance and load-bearing capacity are crucial for maintaining operational efficiency. The versatility of cast iron bearings allows them to be designed in various shapes and sizes to fit different equipment requirements.

Manufacturing Processes

The manufacturing of cast iron bearings typically involves the sand casting process, where molten cast iron is poured into molds to create the desired bearing shape. The casting process allows for intricate designs and precise dimensions, ensuring that the bearings fit accurately within their respective applications. Following casting, the bearings undergo machining processes such as grinding and finishing to achieve smooth surfaces and tighter tolerances.

Conclusion

Cast iron bearings play a vital role in numerous mechanical applications, thanks to their unique properties and advantages. From automotive and aerospace to industrial machinery, their durability and cost-effectiveness make them an essential choice for engineers and designers. As technology advances, the manufacturing processes and applications for cast iron bearings are expected to evolve, paving the way for even more innovative uses in the future. As industries continue to prioritize efficient and reliable solutions, cast iron bearings will undoubtedly remain a critical component in the world of engineering.