Mobile:+86-311-808-126-83

Email:info@ydcastings.com

Affordable Casting Sand Available for Purchase and Immediate Delivery

The Rising Demand for Casting Sand A Treasure in the Industrial Landscape

In today's industrial world, the demand for high-quality casting sand is witnessing an unprecedented surge. This essential raw material plays a pivotal role in various manufacturing processes, particularly in foundries and metalworking industries. As a result, the market for casting sand for sale is expanding, driven by advancements in technology, an increase in production capabilities, and a growing understanding of its significance.

Understanding Casting Sand

Casting sand, primarily composed of silica, is a granular material used to create molds for metal casting. Its unique properties, including a high melting point, excellent thermal stability, and the ability to retain shapes, make it an ideal medium for producing intricate and precise metal components. The most common type of casting sand is silica sand, although other types, such as olivine sand and zircon sand, are also utilized depending on specific industry requirements.

Industries Reliant on Casting Sand

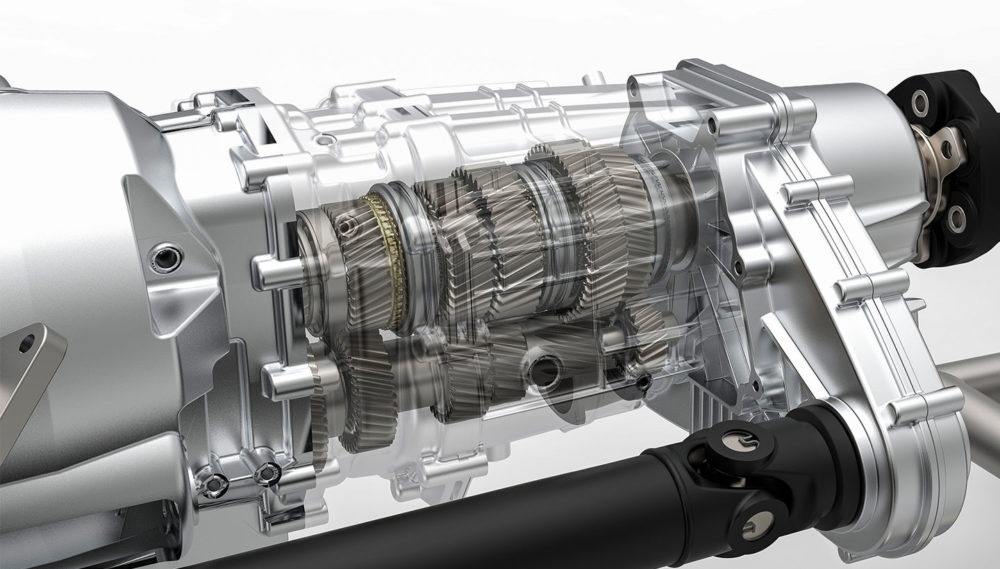

The application of casting sand spans across various sectors, including automotive, aerospace, and machinery manufacturing. In the automotive industry, for instance, casting sand is essential for creating engine blocks, transmission cases, and other critical components. The aerospace sector heavily relies on casting techniques to produce lightweight yet sturdy components crucial for aircraft performance. Furthermore, metal fabricators utilize casting sand for artistic and architectural projects, underscoring its versatility beyond traditional manufacturing.

Market Dynamics and Growth Potential

The growth of the casting sand market is fueled by several factors. Firstly, the rise in global industrialization and urbanization has led to a higher demand for machinery and metal products. This, in turn, amplifies the need for efficient and cost-effective casting solutions. According to industry analysts, the global foundry industry is expected to witness significant growth, and this trajectory directly influences the casting sand market.

Additionally, technological advancements are paving the way for improved casting methods. Innovations such as 3D printing and the use of automation in foundries enhance production efficiency, thereby increasing the demand for superior casting sand. Producers are now seeking high-performance sands that can withstand the rigors of advanced casting processes, creating lucrative opportunities for suppliers in the market.

casting sand for sale

Sustainability Trends and Eco-Friendly Options

While the demand for casting sand continues to rise, there is growing awareness regarding environmental sustainability. Traditional mining practices for silica sand can lead to ecological degradation, prompting industry stakeholders to seek alternative solutions. Reclaimed sand, derived from previous casting processes, is gaining traction as a sustainable option. This not only reduces waste but also addresses concerns related to the over-extraction of natural sand resources.

Moreover, manufacturers are exploring eco-friendly additives to enhance the properties of casting sand, aiming for solutions that minimize environmental impact. The push for green manufacturing processes is shaping the landscape of the casting sand market, enticing environmentally-conscious buyers and investors.

Sourcing Casting Sand for Sale

For businesses in need of high-quality casting sand, sourcing becomes a critical consideration. Many suppliers offer casting sand in various grades and specifications to cater to diverse industry needs. Buyers should assess the quality of the sand, considering factors such as grain size, chemical composition, and thermal properties. Partnering with reputable suppliers ensures that companies receive consistent and reliable materials for their production processes.

Additionally, manufacturers should remain vigilant about market prices, which can fluctuate based on demand and regional availability. Building strong relationships with suppliers and exploring bulk purchasing options can provide cost advantages, thereby enhancing profitability.

Conclusion

The casting sand market is an essential component of modern manufacturing, reflecting the intricate interplay between demand, technological advancements, and sustainability practices. As industries continue to evolve, the quest for high-quality casting sand remains paramount. With an increasing emphasis on eco-friendly solutions and innovative production techniques, the future of casting sand for sale not only promises growth but also emphasizes a responsible approach towards industrial resource management. Embracing these trends will be crucial for companies looking to thrive in an increasingly competitive market.

-

Why Is Choosing the Right Motor Housing Critical for Engine Performance?NewsJul.18,2025

-

Which Impeller Types Best Optimize Your Pump’s Efficiency?NewsJul.18,2025

-

Optimize Maintenance Efficiency with Durable Oil Catch SolutionsNewsJul.18,2025

-

Maximize Pump Performance with Precision-Engineered ComponentsNewsJul.18,2025

-

Elevate Industrial Flow Systems with Precision-Engineered ComponentsNewsJul.18,2025

-

Boost Durability and Functionality with Precision Power CastingsNewsJul.18,2025