Mobile:+86-311-808-126-83

Email:info@ydcastings.com

Casting Aluminum Using Plaster of Paris for Artistic and Industrial Applications

Casting Aluminium in Plaster of Paris A Step-by-Step Guide

Casting is a method widely used in various industries to create intricate designs and components from metals. One popular approach is casting aluminium in plaster of Paris, which serves as an effective mold material. This article outlines the process, benefits, and considerations of using plaster of Paris for casting aluminium.

Understanding Plaster of Paris

Plaster of Paris is a quick-setting material made from gypsum that, when combined with water, forms a paste. Upon hardening, it produces a rigid and detailed mold. The properties of plaster of Paris make it an ideal choice for casting metals, especially in applications such as art, jewelry making, and industrial prototypes. Notably, it has a low thermal expansion coefficient and can withstand moderate temperatures, which is essential when casting metals like aluminium that may reach molten temperatures of approximately 660°C (1220°F).

Preparing for the Casting Process

The first step in the casting process is to prepare the pattern. This can be made from various materials, including wood, plastic, or wax, and should have the desired final shape. The pattern must be smooth and accurately shaped to ensure a perfect cast. Once the pattern is ready, it is essential to coat it with a release agent, such as petroleum jelly or commercial mold release products, to facilitate easy removal from the mold afterward.

Creating the Mold

To create a mold, you start by mixing plaster of Paris with water according to the manufacturer's instructions. Typically, a ratio of water to plaster around 12 or 13 works well, but trial and error may be necessary to find the optimal mix for your specific application. Once mixed, the plaster should be poured around the pattern in a vibration-resistant setup to prevent air bubbles. It is critical to allow the plaster ample time to set, usually between 30 minutes to a few hours, depending on thickness and environmental conditions.

After the plaster has hardened completely, the next step is demolding. Carefully remove the plaster from the pattern, ensuring you do not break it. It is generally advisable to wait 24 hours to allow the mold to cure fully, thus increasing its durability.

casting aluminium in plaster of paris

Preparing for Aluminium Casting

Before casting aluminium, the mold should be preheated. This preheating process will help reduce thermal shock and ensure that the plaster does not crack when molten aluminium is introduced. A temperature of around 200°C to 300°C is recommended. Additionally, the aluminium must be prepared; this involves melting it in a furnace or using a suitable heating method until it reaches a liquid state.

The Casting Process

Once everything is prepared, it is time to pour the molten aluminium into the mold. Carefully pour from a ladle or similar container, ensuring a steady flow to avoid causing air pockets. Filling the mold can be a delicate operation, as any sudden movements can lead to deformities or incomplete casts.

After pouring, allow the aluminium to cool and solidify. This can take anywhere from a few minutes to several hours, depending on the size and complexity of the cast. Once cooled, the plaster mold can be gently broken away to reveal the cast aluminium object.

Finishing Touches

Post-casting, the aluminium piece may require some finishing work. This can involve trimming off any excess metal, sanding down rough edges, or polishing the surface to achieve the desired appearance.

Conclusion

Casting aluminium in plaster of Paris can be a rewarding and creative endeavor, whether for practical purposes or artistic expressions. By following the steps outlined and being mindful of the properties and limitations of both the material and process, you can create unique aluminium casts that showcase your talents and fulfill your project requirements. Whether you are a hobbyist or a professional, mastering this technique opens up a myriad of possibilities in the realm of metalworking.

-

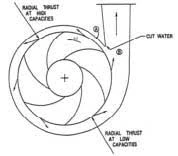

Impeller Technology That Powers Precision in Pump SystemsNewsMay.22,2025

-

Valve Durability Begins with Quality Cast Iron ComponentsNewsMay.22,2025

-

Performance Cooling with Advanced Automobile Water Pump SolutionsNewsMay.22,2025

-

How Motor Housing and Oil Pans Shape Engine PerformanceNewsMay.22,2025

-

How Metal Castings Drive Modern Manufacturing EfficiencyNewsMay.22,2025

-

Exploring the Engineering Behind Valve Body CastingsNewsMay.22,2025