Mobile:+86-311-808-126-83

Email:info@ydcastings.com

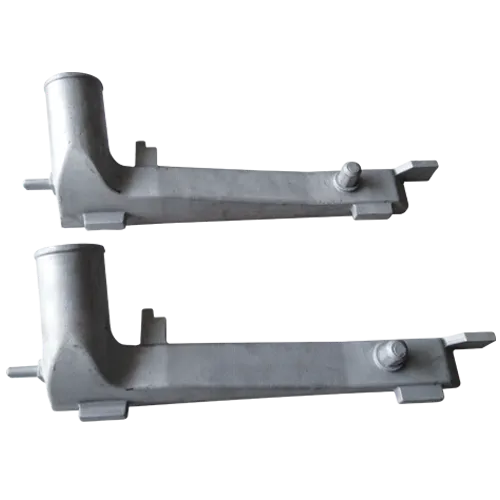

casting 7075 aluminum

Understanding Casting 7075 Aluminum Properties and Applications

Aluminum alloys are renowned for their lightweight and strong characteristics, making them an essential material in various industries. Among these alloys, 7075 aluminum stands out due to its exceptional strength and versatility. This article will explore the properties of 7075 aluminum, its casting processes, and its diverse applications in different fields.

Properties of 7075 Aluminum

7075 aluminum alloy is primarily composed of zinc, along with smaller amounts of magnesium, copper, and chromium. This unique composition grants it remarkable mechanical properties, making it one of the strongest aluminum alloys available. Here are some key attributes of 7075 aluminum

1. High Strength 7075 aluminum boasts an impressive tensile strength range, typically between 570 to 700 MPa (megapascals). This high strength-to-weight ratio makes it an ideal choice for applications requiring durable yet lightweight materials.

2. Low Density Aluminum is inherently lightweight, and 7075 is no exception. Its density is approximately 2.81 g/cm³, making it suitable for applications in aerospace and automotive industries, where reducing weight is crucial.

3. Good Corrosion Resistance While not as resistant as other aluminum alloys, 7075 demonstrates reasonable corrosion resistance, especially when properly treated with coatings or anodizing. This property is essential for components exposed to harsh environments.

4. Workability Although 7075 aluminum is less malleable than some other aluminum alloys, it can be effectively machined and welded with appropriate techniques. Its ability to be heat-treated further enhances its mechanical properties.

Casting Processes of 7075 Aluminum

Casting is a prevalent manufacturing process for producing complex shapes in 7075 aluminum. Various casting methods are employed, including

1. Sand Casting This method involves creating a mold from sand and pouring molten aluminum into the cavity. Sand casting is cost-effective for low production volumes and allows for intricate designs. However, surface finish and dimensional accuracy may not match that of other methods.

casting 7075 aluminum

2. Die Casting Die casting involves forcing molten aluminum into a steel mold under high pressure. This technique provides excellent dimensional accuracy and surface finish, making it suitable for high-volume production. Die-cast 7075 components are often used in applications requiring precision parts.

3. Investment Casting This process utilizes a wax pattern coated with a ceramic shell. Once the shell hardens, the wax is melted away, leaving a cavity for pouring molten aluminum. Investment casting offers high precision and is ideal for complex shapes. It is often used for aerospace components where intricate designs and tolerances are critical.

Applications of 7075 Aluminum

The unique properties of 7075 aluminum make it desirable in several industries

1. Aerospace Due to its high strength and low weight, 7075 aluminum is extensively used in aerospace applications, including aircraft structures, wings, and landing gear components.

2. Automotive The automotive industry employs 7075 aluminum in high-performance vehicles, racing cars, and components that demand both strength and lightness.

3. Military 7075 aluminum's robustness makes it suitable for military applications, including armor plating and equipment frames.

4. Sporting Goods From bicycle frames to golf clubs, 7075 aluminum is favored for its durability and lightweight characteristics, enhancing performance in sports equipment.

Conclusion

7075 aluminum is a remarkable alloy that combines strength, low weight, and good workability, making it a preferred choice for various demanding applications. Its casting methods, whether sand casting, die casting, or investment casting, allow manufacturers to produce complex shapes with high precision. As industries continue to innovate and seek out advanced materials, the role of 7075 aluminum in engineering and design is only expected to grow, highlighting its importance in the modern manufacturing landscape.

-

Why Should You Invest in Superior Pump Castings for Your Equipment?NewsJun.09,2025

-

Unlock Performance Potential with Stainless Impellers and Aluminum End CapsNewsJun.09,2025

-

Revolutionize Your Machinery with Superior Cast Iron and Aluminum ComponentsNewsJun.09,2025

-

Revolutionize Fluid Dynamics with Premium Pump ComponentsNewsJun.09,2025

-

Optimizing Industrial Systems with Essential Valve ComponentsNewsJun.09,2025

-

Elevate Grid Efficiency with High-Precision Power CastingsNewsJun.09,2025