Mobile:+86-311-808-126-83

Email:info@ydcastings.com

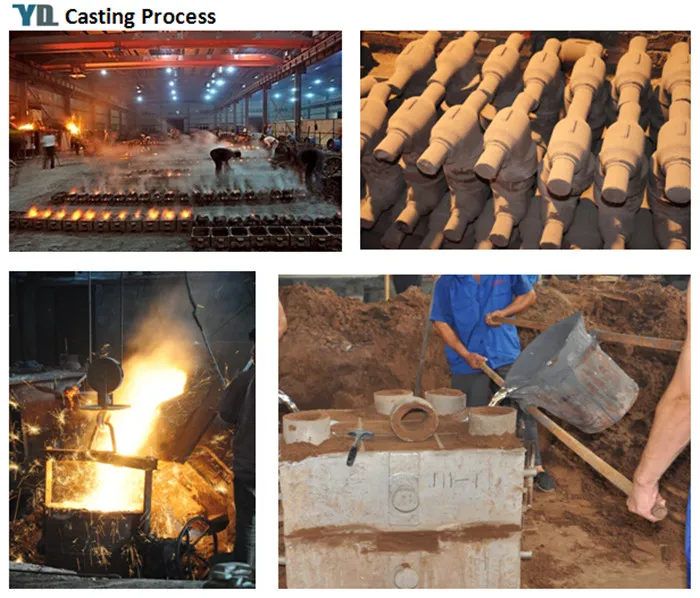

casting process

Understanding the Casting Process in Manufacturing

The casting process is a fundamental manufacturing technique that has been used for centuries to shape materials into specific forms. This technique involves pouring liquid metal or other materials into a mold where it solidifies and takes the shape of the mold. Casting is widely employed in various industries, notably in automobile manufacturing, aerospace, and art.

The casting process begins with designing a mold, which is typically made from materials such as sand, metal, or ceramic, depending on the desired outcome and the material being cast. The mold's design must account for the thermal expansion of the material, the flow of the liquid into the mold, and the ability to remove the finished product without damaging it. Once the mold is prepared, the next step involves melting the casting material. Common metals used include aluminum, iron, steel, and brass, each selected for its specific properties and applications.

Once the metal reaches its molten state, it is carefully poured into the mold. The pouring process must be done with precision to avoid defects such as air pockets or uneven surfaces. After the liquid metal fills the mold, it cools and solidifies, going through a phase change that transforms it from liquid back to solid. The cooling time can vary significantly depending on the material and the thickness of the casting.

casting process

After the metal has fully cooled, the mold is removed to reveal the cast object. This stage often involves shaking out sand molds, or mechanically breaking apart metal molds, which can be a delicate process. The resulting casting may require additional finishing processes, such as machining, polishing, or surface treatment, to achieve the desired quality and specifications.

One of the primary advantages of the casting process is its ability to produce complex shapes that would be difficult or impossible to achieve through other methods. Additionally, casting is suitable for creating large quantities of parts, making it an efficient option for mass production. However, challenges such as defects in the casting, including shrinkage, porosity, and surface imperfections can occur, which necessitate quality control measures throughout the process.

In conclusion, the casting process is a vital part of modern manufacturing, offering versatility and efficiency in creating a wide range of products. As technology continues to advance, innovations in casting techniques and materials promise even greater precision and capability, further enhancing its role in various industries.

-

Why Should You Invest in Superior Pump Castings for Your Equipment?NewsJun.09,2025

-

Unlock Performance Potential with Stainless Impellers and Aluminum End CapsNewsJun.09,2025

-

Revolutionize Your Machinery with Superior Cast Iron and Aluminum ComponentsNewsJun.09,2025

-

Revolutionize Fluid Dynamics with Premium Pump ComponentsNewsJun.09,2025

-

Optimizing Industrial Systems with Essential Valve ComponentsNewsJun.09,2025

-

Elevate Grid Efficiency with High-Precision Power CastingsNewsJun.09,2025