Mobile:+86-311-808-126-83

Email:info@ydcastings.com

Cap Types and Specifications for Pipe End Applications and Installations

Understanding CAP for Pipe End Applications

The concept of CAP, or Capacity Assessment Protocol, is gaining importance in various engineering applications, particularly for pipe ends. This assessment is critical to ensuring that pipes, especially at their terminations, can withstand the conditions imposed by operational demands. In industries such as oil and gas, water distribution, and chemical processing, understanding the capacity of pipe ends is essential to maintain safety and efficiency.

The Importance of Pipe End Capacity Assessment

Every piping system consists of various sections and components, but it is often the ends of the pipes that face the most significant stress. Pipe ends are the points where connections are made to other pipes, fittings, valves, or equipment. As such, they are subjected to various forces, including internal pressure, external loads, bending moments, and thermal expansion. The capacity of a pipe end indicates how much load it can handle without failing, which is critical to avoiding potential leaks, ruptures, or catastrophic failures.

Factors Influencing Pipe End Capacity

Several factors influence the capacity of pipe ends, including

1. Material Properties The type of material used in pipe construction significantly affects its strength and, consequently, its capacity. Common materials include steel, PVC, and stainless steel, each with unique characteristics such as tensile strength, corrosion resistance, and thermal stability.

2. Pipe Diameter and Wall Thickness Larger diameter pipes may have a higher capacity, but this is often counterbalanced by wall thickness. Thicker walls can provide additional strength, while thinner walls may reduce weight and cost but compromise structural integrity.

3. Joint Design The way pipe ends are joined or connected to other components can impact their overall capacity. Welded joints, flanged connections, and threaded fittings each have different strength characteristics and failure modes. Proper design and a thorough understanding of joint mechanics are essential.

4. Operational Conditions The environment in which the pipe will operate (temperature, pressure, corrosive substances) also plays a key role. Pipes used in high-pressure systems or that carry aggressive chemicals require special materials and designs to enhance capacity and durability.

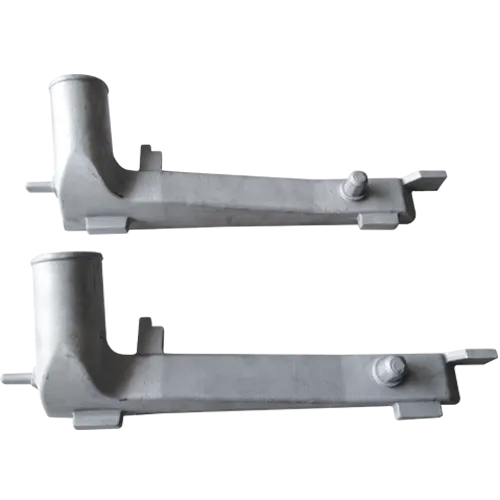

cap for pipe end

5. Installation Quality How well the pipe ends are installed can greatly influence their performance. Inadequate installation techniques can lead to misalignments, stress concentrations, and premature failure.

CAP Assessment Techniques

To determine the capacity of pipe ends, engineers employ various assessment techniques

1. Finite Element Analysis (FEA) This computational tool helps simulate real-world conditions by applying loads to the digital representation of a pipe system to predict stress and deformation.

2. Flexural and Tensile Testing Physical tests can provide critical data on how materials behave under bending or stretching, helping to validate design assumptions or material selections.

3. Hydrostatic Testing This involves filling the pipe with water and applying pressure to ensure that it can handle operational pressures without leaking or bursting.

4. Inspection and Maintenance Programs Regular inspection of pipeline systems helps in identifying any degradation, corrosion, or damage at pipe ends, allowing for preventive measures to be taken before failures occur.

Conclusion

The assessment of capacity for pipe ends is an essential practice in several industries. Engineers must carefully consider various factors, including material properties, design intricacies, and operational conditions, to ensure the integrity and reliability of piping systems. As technology continues to evolve, the methods for assessing and enhancing the capacity of pipe ends will also improve, further safeguarding industrial processes and infrastructure from the risks associated with pipe failure. Adopting best practices and regular assessments will not only enhance safety but also improve the longevity and efficiency of piping systems across various applications.

-

Why Should You Invest in Superior Pump Castings for Your Equipment?NewsJun.09,2025

-

Unlock Performance Potential with Stainless Impellers and Aluminum End CapsNewsJun.09,2025

-

Revolutionize Your Machinery with Superior Cast Iron and Aluminum ComponentsNewsJun.09,2025

-

Revolutionize Fluid Dynamics with Premium Pump ComponentsNewsJun.09,2025

-

Optimizing Industrial Systems with Essential Valve ComponentsNewsJun.09,2025

-

Elevate Grid Efficiency with High-Precision Power CastingsNewsJun.09,2025