Mobile:+86-311-808-126-83

Email:info@ydcastings.com

brass die casting

The Process and Benefits of Brass Die Casting

Brass die casting is a manufacturing process that utilizes molten brass to produce intricate metal parts with high precision and durability. This method is widely adopted across various industries, including automotive, aerospace, electronics, and plumbing, due to its efficiency and ability to create complex shapes with excellent surface finishes.

The die casting process begins with the preparation of the brass alloy, which typically consists of copper and zinc. The desired properties of the final product determine the specific ratio of these metals. Once the alloy is melted in a furnace, it is injected at high pressure into a pre-made mold, known as a die. The die is often made from hardened steel to withstand the high temperatures and pressures associated with the casting process.

One of the primary advantages of brass die casting is its ability to produce parts that are both lightweight and strong. The inherent properties of brass, including its corrosion resistance and aesthetic appeal, make it an ideal choice for applications where durability and appearance are critical. For instance, in the automotive industry, brass components are used in fuel systems and electrical connectors, where exposure to harsh environments is common.

brass die casting

Moreover, brass die casting allows for high-volume production with minimal waste

. Once the die is created, thousands of identical parts can be produced quickly, significantly reducing production costs compared to traditional machining methods. This efficiency makes it an attractive option for manufacturers looking to scale production without sacrificing quality.Another significant benefit of brass die casting is the flexibility it offers in design. The process enables the creation of complex geometries that would be difficult or impossible to achieve with other manufacturing techniques. Additionally, the smooth surface finish of die-cast parts reduces the need for extensive post-casting machining, further cutting down on production time and costs.

However, while brass die casting presents numerous advantages, it is essential to consider some limitations as well. The initial cost of creating a die can be high, making it less economical for low-volume production runs. Additionally, specific design considerations must be taken into account to avoid defects such as porosity or improper filling of the mold.

In conclusion, brass die casting is a highly efficient manufacturing process that combines strength, durability, and aesthetic appeal. Its ability to produce complex parts quickly and at a lower cost makes it a valuable option for many industries. As technology advances and the demand for high-quality components continues to rise, the relevance of brass die casting in the manufacturing landscape is likely to grow, solidifying its place as a preferred choice for producing premium metal parts. Whether for intricate electronics or robust automotive applications, the benefits of this technique are clear and substantial.

-

Why Is Choosing the Right Motor Housing Critical for Engine Performance?NewsJul.18,2025

-

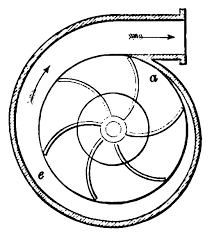

Which Impeller Types Best Optimize Your Pump’s Efficiency?NewsJul.18,2025

-

Optimize Maintenance Efficiency with Durable Oil Catch SolutionsNewsJul.18,2025

-

Maximize Pump Performance with Precision-Engineered ComponentsNewsJul.18,2025

-

Elevate Industrial Flow Systems with Precision-Engineered ComponentsNewsJul.18,2025

-

Boost Durability and Functionality with Precision Power CastingsNewsJul.18,2025