Mobile:+86-311-808-126-83

Email:info@ydcastings.com

Types of Blower Impellers and Their Applications in Various Industries

Understanding Blower Impeller Types An Overview

Blowers are integral components in various industrial processes, enhancing air movement and managing airflow across applications such as ventilation, cooling, and pneumatic conveying. One of the most critical elements of a blower is its impeller, which directly influences the blower's efficiency, performance, and suitability for specific tasks. This article delves into the various types of blower impellers, their design characteristics, and their applications.

1. Centrifugal Impellers

Centrifugal impellers are among the most commonly used types in blowers. They work by converting rotational energy, typically from an electric motor, into kinetic energy in the air. The design consists of blades arranged in a radial pattern, which accelerates the air outward, generating high-pressure airflow. Their advantages include a straightforward design, ability to handle large volumes of air, and suitability for applications requiring high pressure and medium to high flow rates.

Centrifugal impellers can be further classified into several subtypes, including closed, open, and semi-open impellers. Closed impellers, which have both an upper and lower shroud, are efficient and commonly used in HVAC systems. Open impellers lack a shroud and are often used for handling dirty or corrosive gases, while semi-open impellers provide a balance, offering decent efficiency and moderate capacity for particulates.

Axial impellers operate quite differently from centrifugal ones. Instead of pushing the air outward, axial impellers move air along the axis of rotation, similar to a propeller. This design is particularly effective for applications requiring high flow rates but lower pressure increases. Axial impellers are ideal for ventilation systems, cooling towers, and applications that necessitate transporting large volumes of air with minimal resistance.

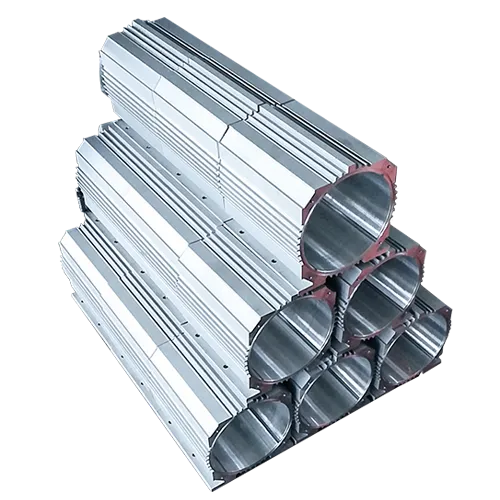

blower impeller types

3. Mixed Flow Impellers

Mixed flow impellers combine features of both centrifugal and axial designs. They generate airflow in a direction that is both radial and axial, providing a medium pressure and flow rate output. This type is beneficial in applications where space is constrained and high efficiency is necessary, serving as a versatile option across different sectors. Mixed flow impellers are frequently used in commercial and industrial blowers, particularly in systems that need to efficiently move air while dealing with varying pressure requirements.

4. Fan Blades Styles

The blade design of the impeller plays a vital role in its performance. Blade angle, length, and shape can all significantly affect a blower’s efficiency. For instance, high tip speed blades are more suitable for generating high pressure, whereas wider blades can handle larger volumes of airflow but may suffer from efficiency losses at higher velocities. Variables such as the material used (metal, plastic, or composite) and the manufacturing process can also contribute to the overall performance of the impeller.

5. Selecting the Right Impeller

Choosing the appropriate blower impeller type depends on the specific needs of the application. Factors such as required airflow volume, pressure levels, the cleanliness of the air handled, and space constraints must all be considered. Industrial processes that involve particulate-laden air may favor open or semi-open impellers, while applications requiring tight control over airflow pressure may opt for closed centrifugal impellers.

Finally, advancements in technology continue to improve the design and manufacturing of impellers, paving the way for more efficient, durable, and cost-effective blower systems. By understanding the different types of blower impellers, engineers and facility managers can make more informed decisions, resulting in streamlined operations and enhanced energy efficiency in their processes.

-

Understanding Metal Casting TechniquesNewsApr.02,2025

-

Understanding Exhaust Manifolds for Enhanced Engine PerformanceNewsApr.02,2025

-

The World of Metal FabricationNewsApr.02,2025

-

Key Components for Pump and Turbo EfficiencyNewsApr.02,2025

-

Essential Tools for Automotive Maintenance and RepairNewsApr.02,2025

-

Durable Valve Components for Effective Water ManagementNewsApr.02,2025