Mobile:+86-311-808-126-83

Email:info@ydcastings.com

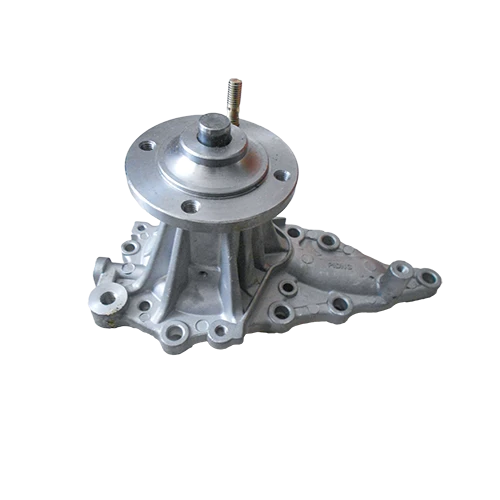

blower fan impeller

The Importance of Blower Fan Impellers in Modern Engineering

In the realm of modern engineering and technology, the blower fan impeller plays a critical role in the effective conversion of electrical energy into airflow. These impellers are essential components in various applications that require efficient air movement, including HVAC systems, industrial ventilation, and cooling systems. Understanding their design, functionality, and impact on overall system performance is crucial for engineers and technicians alike.

A blower fan impeller is typically a rotating device equipped with blades that propel air through a system. The design of the impeller is pivotal; it directly affects the efficiency of air movement, noise levels, and overall energy consumption. Two common types of impellers are the centrifugal and axial impellers. Centrifugal impellers utilize a series of blades arranged around a central hub, forcing air outward through the rotational motion. In contrast, axial impellers push air along the axis of the fan, creating a flow that is often favored in applications requiring high air volume at low pressure.

The choice between these two types often depends on the specific requirements of the application. Centrifugal impellers are generally preferred when high pressures are required, as they effectively increase air velocity and can produce significant static pressure. Conversely, axial impellers are used in scenarios where a large volume of air needs to be moved with minimal resistance, such as in cooling fans for electronic equipment.

One of the primary considerations in the design of blower fan impellers is the material used. Impellers must withstand not only the forces of rotation but also the environmental conditions of their operating environment. Common materials include high-strength plastics, aluminum, and other metal alloys. The choice of material influences the durability, weight, and cost efficiency of the impeller.

blower fan impeller

Another crucial aspect is the impeller's size and geometry. Larger impellers can displace more air, making them suitable for high-volume applications. However, they can be limited by the space available in the system and may require more energy to rotate. Conversely, smaller impellers might be more energy-efficient but may not deliver the airflow needed for specific applications. Engineers often employ computational fluid dynamics (CFD) simulations to optimize impeller size and shape, ensuring maximum airflow while minimizing energy consumption and noise.

Noise is an often-overlooked factor in the design of blower fan impellers. Excessive noise can lead to discomfort in residential and commercial environments. Therefore, sound attenuation measures are vital in the design stage. By optimizing the shape and arrangement of blades, and by incorporating noise-dampening materials, engineers can significantly reduce operational noise levels without compromising performance.

The efficiency of blower fan impellers can be quantified through metrics such as airflow (measured in cubic feet per minute or CFM) and total pressure. Efficient impellers not only enhance performance but also contribute to lower operational costs, making them essential for energy-conscious designs.

In conclusion, the blower fan impeller is a fundamental component in many air-moving applications. Its design, materials, and operational parameters directly affect system efficiency, noise levels, and energy consumption. By understanding the intricacies of impeller function and design, engineers can create optimized systems that meet the demands of modern industries and contribute to more sustainable and efficient technology solutions. As engineering continues to evolve, the importance of advanced blower fan impeller design will undoubtedly remain at the forefront of air movement technology.

-

Why Should You Invest in Superior Pump Castings for Your Equipment?NewsJun.09,2025

-

Unlock Performance Potential with Stainless Impellers and Aluminum End CapsNewsJun.09,2025

-

Revolutionize Your Machinery with Superior Cast Iron and Aluminum ComponentsNewsJun.09,2025

-

Revolutionize Fluid Dynamics with Premium Pump ComponentsNewsJun.09,2025

-

Optimizing Industrial Systems with Essential Valve ComponentsNewsJun.09,2025

-

Elevate Grid Efficiency with High-Precision Power CastingsNewsJun.09,2025