Mobile:+86-311-808-126-83

Email:info@ydcastings.com

Black Pipe Cap for Industrial Applications and Home Use Solutions

Understanding Black Pipe Caps A Comprehensive Overview

Black pipe caps play a crucial role in various piping systems across different industries. Manufactured from high-quality materials, these caps are specifically designed to seal the ends of black steel pipes, ensuring a secure and leak-free connection. In this article, we will explore the definition, types, applications, and advantages of black pipe caps, along with installation tips and maintenance advice.

What Are Black Pipe Caps?

Black pipe caps are fittings that are used to close off the ends of black iron pipes. The term 'black' refers to the pipe's dark, matte finish, which is a result of the manufacturing process that leaves a layer of iron oxide on the surface. This black finish not only provides an aesthetically pleasing look but also offers enhanced protection against corrosion in specific environments. The primary function of these caps is to prevent the flow of fluids and gases through the pipe, making them essential for maintaining system integrity.

Types of Black Pipe Caps

There are numerous types of black pipe caps available, classified mainly by their design and connection method

1. Standard Caps These are the most common type and feature a simple design used to close off the end of a pipe.

2. Threaded Caps These caps have internal threads that allow them to screw onto a corresponding threaded black pipe, providing a secure connection.

3. Welded Caps These require welding to attach the cap securely to the pipe, making them ideal for high-pressure applications.

4. Slip Caps Designed to slip over the end of the pipe, these caps provide a quick and easy way to seal off the end without threads or welding.

Each type has its unique set of advantages and is suitable for various applications, depending on the specific needs of the project.

Applications of Black Pipe Caps

Black pipe caps are commonly used in several industries, including

- Plumbing In plumbing systems, black pipe caps are used to seal off unfinished runs of piping, preventing leaks and ensuring safety

.- Gas Lines These caps are often utilized in natural gas and propane applications to safely terminate pipe runs.

- Oil and Gas In oil and gas industries, black iron caps are vital for closing off lines and maintaining pressure in pipelines.

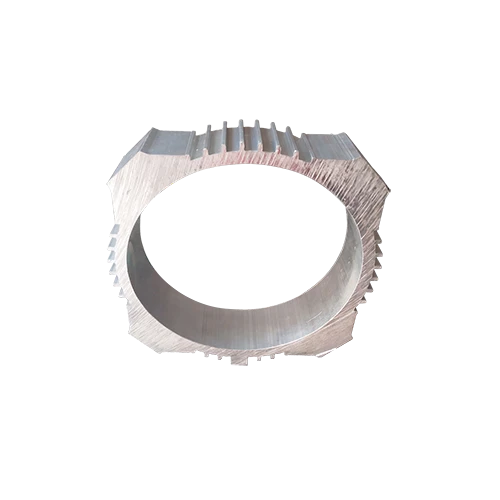

black pipe cap

- Mechanical Systems They are also used in mechanical systems where a pipe needs to be temporarily capped for maintenance or modifications.

Advantages of Black Pipe Caps

The use of black pipe caps offers several advantages

1. Durability Black steel is known for its high strength and resistance to impact, ensuring longevity in demanding environments.

2. Corrosion Resistance The black finish helps protect against mild corrosive conditions, extending the life of the piping system.

3. Versatility Available in various sizes and configurations, black pipe caps can accommodate diverse applications, making them a one-stop solution for pipe sealing needs.

4. Ease of Installation Depending on the type, installation can be straightforward whether using threading, welding, or simply sliding the cap onto the pipe.

Installation and Maintenance Tips

When installing black pipe caps, follow these guidelines

- Ensure Compatibility Verify that the cap size matches the pipe size for a proper fit.

- Clean Surfaces Before capping, clean the pipe ends to remove any debris, oil, or rust, which can prevent a secure seal.

- Follow Manufacturer Instructions Always adhere to specific manufacturer guidelines for installation methods and torque specifications.

For maintenance, regularly inspect capped pipes for any signs of corrosion or leaks and replace caps as needed to maintain system integrity.

Conclusion

In conclusion, black pipe caps are essential fittings in a plethora of applications, known for their practicality and durability. Understanding the various types, applications, and advantages can aid in making informed decisions during installations in plumbing or industrial contexts. By following proper installation and maintenance practices, users can ensure the longevity and reliability of their piping systems.

-

Why Should You Invest in Superior Pump Castings for Your Equipment?NewsJun.09,2025

-

Unlock Performance Potential with Stainless Impellers and Aluminum End CapsNewsJun.09,2025

-

Revolutionize Your Machinery with Superior Cast Iron and Aluminum ComponentsNewsJun.09,2025

-

Revolutionize Fluid Dynamics with Premium Pump ComponentsNewsJun.09,2025

-

Optimizing Industrial Systems with Essential Valve ComponentsNewsJun.09,2025

-

Elevate Grid Efficiency with High-Precision Power CastingsNewsJun.09,2025