Mobile:+86-311-808-126-83

Email:info@ydcastings.com

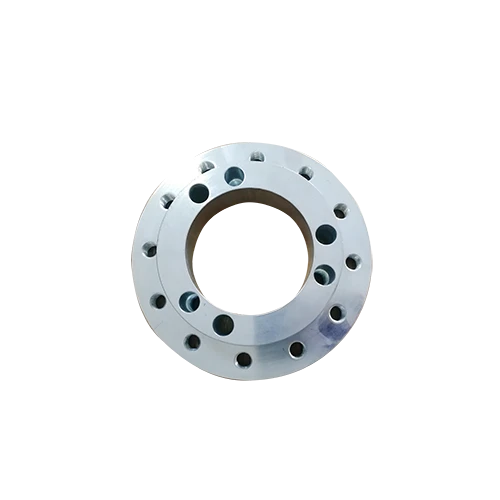

black iron valve

Understanding Black Iron Valves Importance and Applications

In various industries, valves play a crucial role in controlling the flow of fluids and gases. Among the several types of valves available, black iron valves are notable for their robustness, reliability, and versatility. These valves are primarily made from black iron, a type of cast iron that has not been coated or treated, giving it a distinctive dark appearance. This article explores the significance, applications, and maintenance of black iron valves.

What Are Black Iron Valves?

Black iron valves are typically constructed from malleable or ductile iron, allowing them to withstand high pressure and temperature variations. These valves are designed to regulate or isolate the flow of fluids such as water, oil, and gas. The black iron material is notable for its durability and strength, making it an excellent choice for industrial applications and plumbing systems where reliability is paramount.

Importance of Black Iron Valves

The significance of black iron valves can be understood through their longevity, resistance to corrosion, and ability to handle high-pressure situations effectively. Unlike some other materials that may degrade over time or under high-stress conditions, black iron valves are robust and can endure harsh environments, which is essential in industries that operate machinery continuously.

Moreover, black iron valves are capable of withstanding significant pressure surges, making them ideal for oil and gas pipelines. They facilitate safe and efficient transportation of these essential resources, contributing to the overall infrastructure of energy supply chains. This reliability earns them favor among engineers and maintenance professionals who require dependable components in their systems.

Applications of Black Iron Valves

black iron valve

The applications of black iron valves are vast and varied. They are predominantly utilized in plumbing systems for residential and industrial buildings. In homes, they may be found in heating systems, electrical power plants, and HVAC systems. Industrial applications extend to oil refineries, gas processing plants, and chemical manufacturing, where precise control of fluid flow is crucial.

In addition, black iron valves are often used in fire protection systems, where they control the water supply to sprinkler systems. Their ability to handle high-pressure water makes them suitable for this critical safety application. Each application requires specific types of black iron valves, including gate valves, globe valves, and ball valves, each serving distinct functions.

Maintenance of Black Iron Valves

Maintaining black iron valves is vital for ensuring their longevity and optimal performance. Regular inspection should be conducted to check for any signs of wear, corrosion, or leaks. Since black iron is susceptible to rust, particularly in moist environments, proper protective coatings or periodic painting may be necessary to shield the valve from moisture and other corrosive substances.

Another key maintenance aspect involves the careful operation of the valves themselves. Over-tightening or forcing valves can lead to mechanical failure. Therefore, best practices suggest operating these valves within their recommended limits and parameters to prolong their life.

Conclusion

In summary, black iron valves serve as an essential component in a multitude of applications across various industries. Their durability, reliability, and versatility make them a preferred choice for professionals who require robust solutions for fluid and gas control. However, regular maintenance is critical to ensure their continued efficiency and functionality. As industries evolve and advance, black iron valves will likely remain a staple due to their enduring qualities and adaptability to various environments and applications.

-

Why Should You Invest in Superior Pump Castings for Your Equipment?NewsJun.09,2025

-

Unlock Performance Potential with Stainless Impellers and Aluminum End CapsNewsJun.09,2025

-

Revolutionize Your Machinery with Superior Cast Iron and Aluminum ComponentsNewsJun.09,2025

-

Revolutionize Fluid Dynamics with Premium Pump ComponentsNewsJun.09,2025

-

Optimizing Industrial Systems with Essential Valve ComponentsNewsJun.09,2025

-

Elevate Grid Efficiency with High-Precision Power CastingsNewsJun.09,2025