Mobile:+86-311-808-126-83

Email:info@ydcastings.com

Design and Functionality of Bevel Gear Housing in Mechanical Applications

Understanding Bevel Gear Housing A Comprehensive Overview

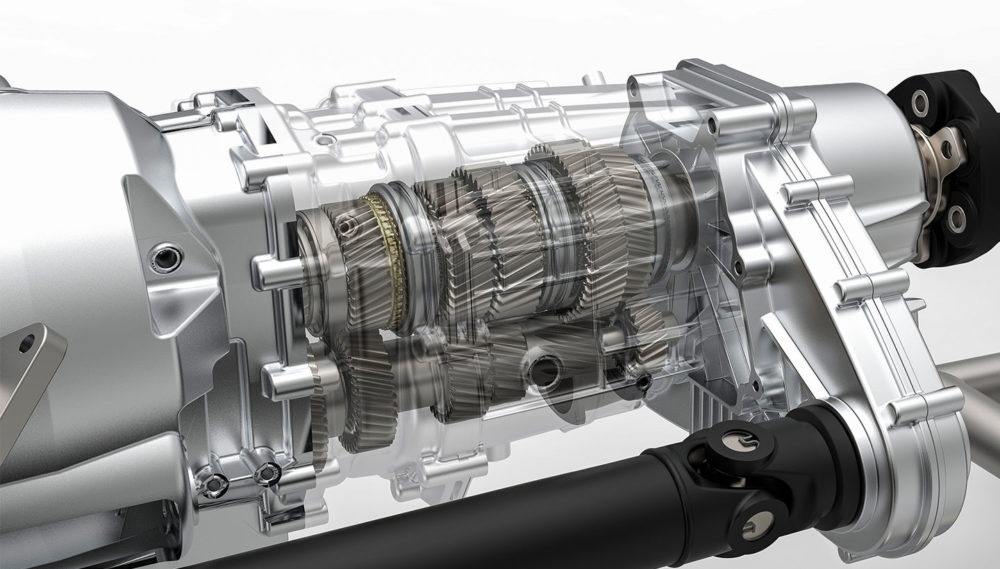

Bevel gears are a critical component in various mechanical systems, serving as a means to transmit power and motion between shafts that are oriented at an angle — typically 90 degrees. The housing in which these gears are contained, known as bevel gear housing, plays a pivotal role in ensuring that these gears operate efficiently and reliably. This article delves into the significance, design considerations, and applications of bevel gear housing.

What is Bevel Gear Housing?

Bevel gear housing is an encasement designed to contain bevel gears while providing protection and support. It serves multiple essential functions, including maintaining proper gear alignment, preventing contamination from external elements, and absorbing vibrations during operation. Usually constructed from robust materials like cast iron, aluminum, or reinforced steel, the housing's architecture can take various forms depending on the requirements of the application it serves.

Importance of Bevel Gear Housing

1. Alignment and Support Proper gear alignment is crucial for the smooth operation of bevel gears. The housing provides a fixed structure that maintains the necessary distance and angle between the gears, thereby reducing wear and tear and extending their operational life.

2. Protection from Contamination Bevel gears are susceptible to damage from dirt, dust, moisture, and other contaminants. A well-designed housing provides a protective barrier that helps keep the gears clean, thereby ensuring optimal performance.

3. Heat Dissipation During operation, bevel gears generate heat due to friction. The housing helps dissipate this heat, either through its own thermal properties or by facilitating airflow, thereby preventing overheating and potential gear failure.

4. Noise and Vibration Control Bevel gear systems can generate significant noise and vibration. The housing can be engineered to dampen these effects, contributing to quieter operation and reducing wear on the components.

5. Improved Safety By enclosing the gears, the housing decreases the risk of accidents. It prevents accidental contact with moving parts, ensuring a safer working environment.

Design Considerations

When designing bevel gear housing, several factors must be taken into account

- Material Selection The choice of materials affects the strength, weight, cost, and thermal properties of the housing. Engineers often select materials based on the specific requirements of the application and the operating environment.

bevel gear housing

- Geometric Configuration The design must accommodate the size and orientation of the bevel gears, ensuring sufficient space for movement while minimizing the overall footprint of the assembly.

- Mounting and Integration The housing needs to be designed for easy mounting onto existing structures, making integration into larger systems seamless. This includes considering various fastening methods and alignment features.

- Sealing Options Effective sealing solutions must be implemented to prevent the ingress of contaminants while allowing smooth operation. This is particularly important in harsh environments where dust and moisture are prevalent.

- Heat Management Depending on the operational conditions, the housing design may require features to facilitate heat dissipation, such as vents or heat sinks.

Applications of Bevel Gear Housing

Bevel gear housings are utilized in a multitude of applications across various industries, including

- Automotive In vehicles, bevel gears are often used in the differential to transfer power from the engine to the wheels, with the housing protecting these gears from road debris and environmental factors.

- Aerospace In aircraft, bevel gears are critical for controlling flight surfaces. The housing ensures that gears operate reliably under extreme conditions.

- Heavy Machinery Industrial applications like cranes and excavators rely on bevel gear systems for steering and hoisting. Robust housing is essential to withstand the demanding operational environment.

- Robotics Bevel gears enable complex movements in robotic systems, requiring precision housing designs that promote accuracy and reliability.

Conclusion

Bevel gear housing is an indispensable component of many mechanical systems. By providing alignment, protection, and support, it ensures that bevel gears function optimally under a variety of conditions. As technology continues to advance, the design and materials used in bevel gear housings will likely evolve, enhancing their performance and expanding their applications across diverse fields. Understanding these nuances is crucial for engineers and designers seeking to leverage bevel gears effectively in their projects.

-

Why Should You Invest in Superior Pump Castings for Your Equipment?NewsJun.09,2025

-

Unlock Performance Potential with Stainless Impellers and Aluminum End CapsNewsJun.09,2025

-

Revolutionize Your Machinery with Superior Cast Iron and Aluminum ComponentsNewsJun.09,2025

-

Revolutionize Fluid Dynamics with Premium Pump ComponentsNewsJun.09,2025

-

Optimizing Industrial Systems with Essential Valve ComponentsNewsJun.09,2025

-

Elevate Grid Efficiency with High-Precision Power CastingsNewsJun.09,2025