Mobile:+86-311-808-126-83

Email:info@ydcastings.com

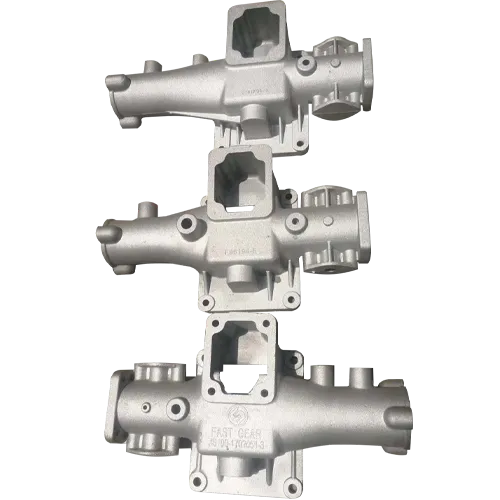

bearing end cap covers

Understanding Bearing End Cap Covers A Critical Component in Machinery

In the world of machinery and engineering, precision and reliability are paramount. One of the often-overlooked components that play a crucial role in ensuring the efficiency and longevity of machinery is the bearing end cap cover. These covers are designed to protect bearings, one of the most critical parts of various mechanical systems. In this article, we will explore what bearing end cap covers are, their functions, materials, installation, and maintenance.

What are Bearing End Cap Covers?

Bearing end cap covers are protective enclosures placed over the ends of bearings in different machinery and equipment. Their primary purpose is to shield the bearing surface from contaminants such as dust, dirt, moisture, and other abrasive particles that can lead to wear and tear. Additionally, these covers help retain lubrication within the bearing, which is vital for its smooth operation. Without adequate protection, bearings can fail, leading to costly downtime and repairs.

Functions of Bearing End Cap Covers

1. Protection from Contaminants The foremost function of bearing end cap covers is to prevent foreign particulates from entering the bearing area. Contaminants can severely hinder the performance of bearings, causing premature failure.

2. Lubrication Retention Proper lubrication is essential for reducing friction and wear between moving parts. End cap covers help in retaining the lubricant within the bearing, ensuring it continues to function efficiently over time.

3. Structural Support These covers also provide structural support to the bearings, helping to maintain their position within the housing and ensuring they operate at optimal angles.

4. Easy Access for Maintenance In many designs, bearing end cap covers allow for quick access to the bearings for maintenance checks and lubrication without requiring complete disassembly of the equipment.

Materials Used in Bearing End Cap Covers

Bearing end cap covers can be made from various materials, each chosen for its specific properties. Some of the common materials include

1. Metal Typically made from aluminum or steel, metal end caps are robust and provide excellent protection against physical damage. They are commonly used in heavy machinery where durability is paramount.

2. Plastic Polycarbonate or nylon end caps are lightweight, resistant to corrosion, and can provide adequate protection for bearings in less demanding environments.

bearing end cap covers

Installation of Bearing End Cap Covers

Proper installation of bearing end cap covers is crucial for ensuring that they perform their protective functions effectively. Here are some guidelines for installation

1. Clean the Surface Before installation, ensure that the bearing surface and the area around it are free from dust and contaminants.

2. Align Properly Ensure that the end cap aligns properly with the bearing. Misalignment can lead to improper sealing and may allow contaminants to enter.

3. Secure Fastening Use the appropriate fastening methods (screws, bolts, or clips) to secure the end cap in place. Ensure that they are tightened to the manufacturer’s specifications to avoid loosening during operation.

4. Check for Lubrication Before sealing the end cap, ensure the bearing is properly lubricated. This prevents the risk of friction-related failures post-installation.

Maintenance of Bearing End Cap Covers

Regular maintenance of bearing end cap covers contributes significantly to the lifespan of the bearings they protect. Here are some maintenance tips

1. Inspect Regularly Conduct regular inspections of the end caps for signs of wear, damage, or misalignment. Regular checks will help identify potential issues before they lead to failure.

2. Clean the Exterior Keep the exterior of the end caps clean to prevent debris accumulation, which could lead to corrosion over time.

3. Ensure Proper Lubrication Regularly check the lubrication levels of the bearings. If the covers have been removed for maintenance, ensure they’re properly lubricated before resealing.

4. Replace if Necessary If an end cap cover becomes damaged or worn, it should be replaced immediately to maintain protection levels.

Conclusion

Bearing end cap covers, though small and often overlooked, are vital for the efficient functioning of machinery. They protect bearings from contaminants, retain lubrication, and provide structural support. Investing in high-quality bearing end cap covers, along with ensuring proper installation and regular maintenance, can significantly enhance the longevity and performance of mechanical equipment. Understanding this crucial component can save businesses time and money by preventing machinery breakdowns and ensuring optimal operation.

-

Why Should You Invest in Superior Pump Castings for Your Equipment?NewsJun.09,2025

-

Unlock Performance Potential with Stainless Impellers and Aluminum End CapsNewsJun.09,2025

-

Revolutionize Your Machinery with Superior Cast Iron and Aluminum ComponentsNewsJun.09,2025

-

Revolutionize Fluid Dynamics with Premium Pump ComponentsNewsJun.09,2025

-

Optimizing Industrial Systems with Essential Valve ComponentsNewsJun.09,2025

-

Elevate Grid Efficiency with High-Precision Power CastingsNewsJun.09,2025