Mobile:+86-311-808-126-83

Email:info@ydcastings.com

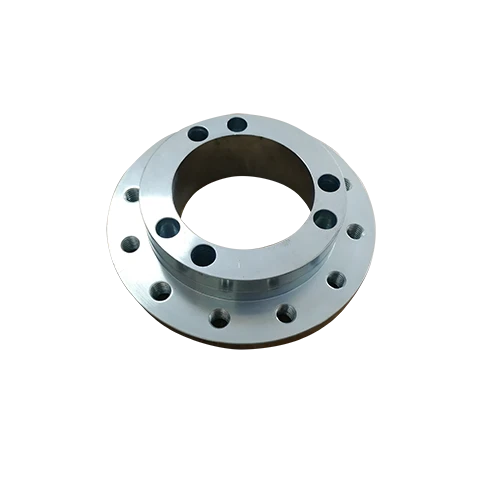

aluminum centrifugal casting

Aluminum Centrifugal Casting An Overview

Aluminum centrifugal casting is an advanced manufacturing process that leverages centrifugal force to produce high-quality aluminum components. This casting technique is recognized for its ability to create parts with superior mechanical properties, dimensional accuracy, and surface finish compared to conventional casting methods. In this article, we will explore the principles of aluminum centrifugal casting, its applications, advantages, and considerations in the manufacturing process.

The Process of Aluminum Centrifugal Casting

The essential principle behind centrifugal casting involves the use of a rotating mold. Typically, a metal mold is preheated and filled with molten aluminum, which is then subjected to rapid rotation. As the mold spins, the molten aluminum is forced against the mold walls due to centrifugal force, resulting in a dense and uniform casting.

There are two primary methods of centrifugal casting vertical and horizontal. In vertical centrifugal casting, the mold is oriented upright, while in horizontal casting, the mold lies flat. The choice of method depends largely on the specific requirements of the part being produced.

Advantages of Aluminum Centrifugal Casting

1. Reduced Porosity One of the main advantages of aluminum centrifugal casting is its ability to produce castings with significantly reduced porosity. The centrifugal force drives gas bubbles towards the center of the mold, minimizing the risk of defects. The resulting components are often stronger and more durable.

2. Superior Mechanical Properties The process effectively enhances the grain structure of the aluminum, resulting in improved tensile strength and ductility. This makes centrifugal castings suitable for applications that require high-performance materials.

3. Dimensional Accuracy The rotational nature of the process allows for tighter tolerances and greater dimensional accuracy. Complex shapes can be cast with precision, reducing the need for extensive machining after casting.

4. Enhanced Surface Finish Components produced through centrifugal casting typically exhibit a much smoother surface finish than those made using traditional methods. This not only improves aesthetics but also reduces the need for further surface treatments.

aluminum centrifugal casting

Applications of Aluminum Centrifugal Casting

Aluminum centrifugal casting is widely used in various industries due to its unique advantages. Some common applications include

1. Automotive Industry Components like cylinder liners, pistons, and transmission cases utilize aluminum centrifugal casting for their strength and lightweight characteristics. This is crucial in enhancing fuel efficiency and overall vehicle performance.

2. Aerospace Components The aerospace sector benefits from aluminum centrifugal castings for parts that require both strength and weight reduction, such as housings and frames.

3. Marine Applications Components exposed to harsh environments, such as ship propellers and hull fittings, often rely on aluminum centrifugal casting for durability and resistance to corrosion.

4. Industrial Equipment Many manufacturing operations utilize aluminum centrifugal castings for gears, bearings, and other machine components that demand high strength and reliability.

Considerations in the Manufacturing Process

Despite its many advantages, manufacturers must be mindful of certain considerations when implementing aluminum centrifugal casting. The quality of the molten aluminum is critical; impurities can significantly affect the final product’s integrity. Additionally, careful control of the temperature and rotational speed is necessary to achieve optimal results and prevent defects.

Mold design is another pivotal factor in the process. The mold must be engineered to withstand high centrifugal forces and temperatures associated with molten aluminum. Using materials with excellent thermal conductivity can enhance the casting's quality by promoting uniform solidification.

Conclusion

Aluminum centrifugal casting is a sophisticated casting method that brings numerous advantages, particularly in producing high-performance components for various industries. Its ability to deliver superior mechanical properties, reduced porosity, and exceptional dimensional accuracy makes it an ideal choice for critical applications. As technology advances, the use of aluminum centrifugal casting is expected to increase, paving the way for innovative solutions in manufacturing and engineering.

-

Why Should You Invest in Superior Pump Castings for Your Equipment?NewsJun.09,2025

-

Unlock Performance Potential with Stainless Impellers and Aluminum End CapsNewsJun.09,2025

-

Revolutionize Your Machinery with Superior Cast Iron and Aluminum ComponentsNewsJun.09,2025

-

Revolutionize Fluid Dynamics with Premium Pump ComponentsNewsJun.09,2025

-

Optimizing Industrial Systems with Essential Valve ComponentsNewsJun.09,2025

-

Elevate Grid Efficiency with High-Precision Power CastingsNewsJun.09,2025