Mobile:+86-311-808-126-83

Email:info@ydcastings.com

Aluminum Sand Casting Foundry - Precision Casting Solutions

Aluminum Sand Casting Foundry A Comprehensive Overview

Aluminum sand casting is a widely utilized manufacturing process in the foundry industry, renowned for its versatility, economic efficiency, and excellent surface finish. The method involves pouring molten aluminum into sand molds, allowing for complex shapes and intricate designs to be produced with relative ease. This approach is particularly favored for small to medium production runs, prototyping, and custom parts manufacturing.

Aluminum Sand Casting Foundry A Comprehensive Overview

One of the significant advantages of aluminum sand casting is its ability to produce lightweight yet strong components. Aluminum is known for its excellent strength-to-weight ratio, making it an ideal choice for industries such as automotive, aerospace, and manufacturing. Cast components can also exhibit excellent corrosion resistance, contributing to their longevity in various applications.

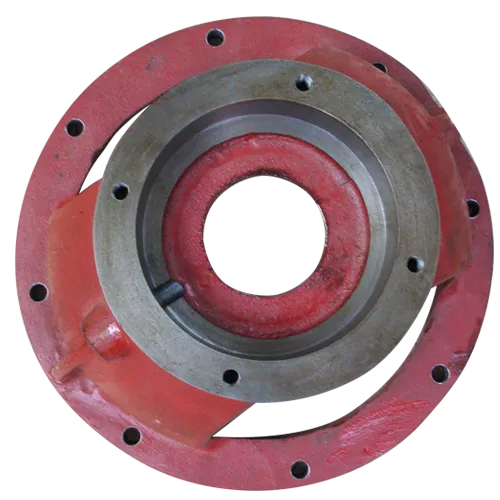

aluminum sand casting foundry

Moreover, aluminum sand casting allows for a high degree of design flexibility. Complex geometries that would be challenging or impossible to achieve with other manufacturing techniques can be efficiently produced through this method. Additionally, it supports low-cost tooling, making it economically viable for both small runs and large-scale production.

Environmental considerations are also increasingly important in modern foundries. Many aluminum sand casting foundries have adopted recycling practices, reusing sand and aluminum scrap to minimize waste. Advanced technologies, such as computer-aided design (CAD) and computer-aided manufacturing (CAM), have further enhanced the precision and efficiency of the casting process.

In conclusion, aluminum sand casting foundries play a crucial role in the manufacturing landscape, providing efficient, cost-effective solutions for a wide range of industries. With ongoing advancements in technology and growing emphasis on sustainability, aluminum sand casting processes are likely to continue evolving, meeting the demands of modern manufacturing while maintaining high standards of quality and efficiency. Whether for prototyping or large-scale production, this method remains a cornerstone of the foundry industry.

-

Why Should You Invest in Superior Pump Castings for Your Equipment?NewsJun.09,2025

-

Unlock Performance Potential with Stainless Impellers and Aluminum End CapsNewsJun.09,2025

-

Revolutionize Your Machinery with Superior Cast Iron and Aluminum ComponentsNewsJun.09,2025

-

Revolutionize Fluid Dynamics with Premium Pump ComponentsNewsJun.09,2025

-

Optimizing Industrial Systems with Essential Valve ComponentsNewsJun.09,2025

-

Elevate Grid Efficiency with High-Precision Power CastingsNewsJun.09,2025