Mobile:+86-311-808-126-83

Email:info@ydcastings.com

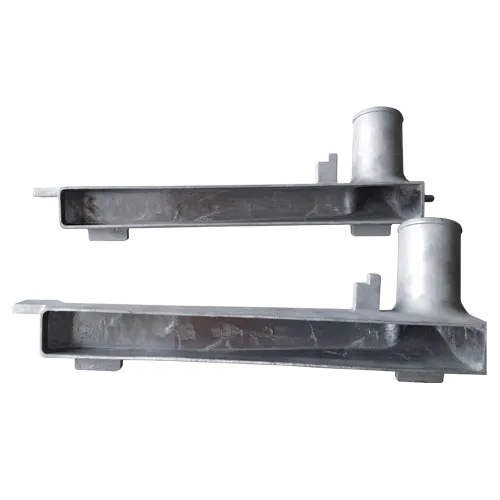

aluminium casting manufacturers

The Role of Aluminium Casting Manufacturers in Modern Industry

Aluminium casting is a critical process in manufacturing, providing the backbone for numerous industries such as automotive, aerospace, consumer goods, and construction. The ability to create complex shapes and structures from aluminium makes this method highly desirable. A crucial component of this industry is the aluminium casting manufacturers, who are instrumental in delivering high-quality products that cater to diverse applications.

The Casting Process

Aluminium casting involves pouring molten aluminium into a mold to achieve desired shapes. There are various methods of casting, including sand casting, die casting, and permanent mold casting. Each method has its unique advantages and is chosen based on the specific requirements of the end product. Sand casting, for instance, is often used for large and complex components, while die casting is preferred for high-volume production due to its efficiency and precision.

The process begins with preparing the mold, which is usually made from sand, metal, or a combination of materials. The molten aluminium is then poured into the mold and allowed to cool and solidify. Once solidified, the casting is removed from the mold, and any finishing processes, such as machining or surface treatment, are applied.

Why Choose Aluminium?

Aluminium is a preferred material for casting due to its lightweight nature, corrosion resistance, and excellent mechanical properties. These qualities make it ideal for manufacturing components that require both strength and durability without adding excessive weight. In the automotive industry, for example, aluminium castings are used extensively in engine blocks and transmission cases, allowing manufacturers to enhance fuel efficiency while maintaining performance standards.

Moreover, aluminium's ability to be easily recycled contributes to its sustainable appeal. With growing concerns over environmental impact, the use of recycled aluminium in the casting process is becoming increasingly prevalent. This not only reduces the demand for raw materials but also minimizes energy consumption and greenhouse gas emissions, aligning production processes with global sustainability goals.

aluminium casting manufacturers

The Importance of Quality Control

Quality control is paramount in aluminium casting. Manufacturers must adhere to strict industry standards and regulations to ensure that the end products meet specific performance and safety criteria. Rigorous testing methods, including dimensional analysis, ultrasonic testing, and X-ray inspection, are employed to detect any defects or inconsistencies in the castings. This commitment to quality helps manufacturers avoid costly recalls and enhances customer trust.

Furthermore, advancements in technology are continually improving the reliability and precision of aluminium casting. Computer-aided design (CAD) and simulation software enable manufacturers to optimize the design and production processes, reducing waste and increasing efficiency. The integration of automation and robotics into casting operations also enhances production capabilities, allowing for higher output with consistent quality.

Challenges and Future Trends

Despite its advantages, the aluminium casting industry faces several challenges, including fluctuating raw material costs and increasing competition from global markets. To remain competitive, manufacturers must invest in innovative technologies and processes that enhance efficiency and reduce costs.

Looking ahead, the future of aluminium casting appears promising. The growing demand for lightweight and high-strength materials in industries like electric vehicles and aerospace is expected to drive further advancements in casting techniques. Additionally, as industries move toward more sustainable practices, manufacturers that can effectively incorporate recycled aluminium into their processes will likely gain a competitive edge.

In conclusion, aluminium casting manufacturers play a vital role in various sectors by providing high-quality, durable, and lightweight products. Their commitment to innovation, quality control, and sustainability will continue to shape the future of manufacturing, making aluminium casting an indispensable part of the modern industrial landscape. With the combination of traditional craftsmanship and cutting-edge technology, the aluminium casting industry is poised for continued growth and innovation.

-

Why Should You Invest in Superior Pump Castings for Your Equipment?NewsJun.09,2025

-

Unlock Performance Potential with Stainless Impellers and Aluminum End CapsNewsJun.09,2025

-

Revolutionize Your Machinery with Superior Cast Iron and Aluminum ComponentsNewsJun.09,2025

-

Revolutionize Fluid Dynamics with Premium Pump ComponentsNewsJun.09,2025

-

Optimizing Industrial Systems with Essential Valve ComponentsNewsJun.09,2025

-

Elevate Grid Efficiency with High-Precision Power CastingsNewsJun.09,2025