Mobile:+86-311-808-126-83

Email:info@ydcastings.com

Properties and Applications of Aluminium Bronze Casting in Various Industries

The Advantages and Applications of Aluminium Bronze Casting

Aluminium bronze is a unique alloy that combines copper, aluminium, and often other elements such as iron, nickel, or manganese to enhance its properties. Known for its exceptional corrosion resistance, strength, and wear resistance, aluminium bronze casting has emerged as a preferred choice for various industrial applications. This article delves into the characteristics, advantages, and uses of aluminium bronze casting.

Characteristics of Aluminium Bronze

Aluminium bronze, primarily composed of copper and aluminium, typically contains between 5% and 12% aluminium. This particular composition endows the alloy with remarkable mechanical properties. It exhibits high tensile strength, good ductility, and impressive resistance to stress corrosion cracking. Additionally, aluminium bronze provides excellent thermal and electrical conductivity, making it ideal for applications that require superior performance under extreme conditions.

The alloy's corrosion resistance is particularly noteworthy, especially in marine environments. Aluminium bronze has the ability to withstand pitting and crevice corrosion, which can severely impact other materials. This makes it an excellent choice for components that are subjected to harsh environments, including seawater and industrial chemicals.

Advantages of Aluminium Bronze Casting

One of the primary advantages of aluminium bronze casting is its durability

. Components made from this alloy can withstand heavy wear and tear, making them suitable for applications in demanding industries such as maritime, aerospace, and oil and gas. The mechanical strength of aluminium bronze allows for thin-walled castings, which reduces weight while maintaining structural integrity.Another significant benefit is its ease of casting. Aluminium bronze can be cast into intricate shapes with high precision, making it ideal for complex components requiring detailed designs. Advanced casting techniques, such as sand casting, investment casting, and pressure die casting, can be employed to produce high-quality aluminium bronze parts efficiently.

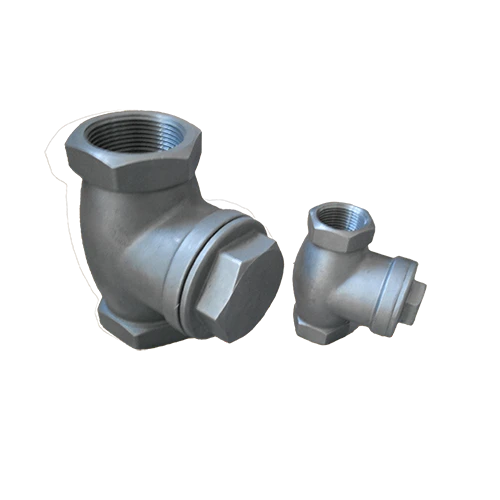

aluminium bronze casting

Aluminium bronze also offers aesthetic advantages, as it has a distinctive golden color that can enhance the visual appeal of finished products. This attribute makes aluminium bronze not only functional but also attractive for architectural applications and decorative elements.

Applications of Aluminium Bronze Casting

The applications of aluminium bronze casting are vast and varied. In the maritime industry, it is commonly used for ship fittings, propellers, and marine hardware due to its excellent resistance to saltwater corrosion. Similarly, in the oil and gas sector, aluminium bronze components are utilized for valves, pumps, and flanges that must endure aggressive environmental conditions.

Moreover, the aerospace industry benefits from aluminium bronze's lightweight and robust characteristics. Components used in aircraft and space vehicles often require materials that can withstand extreme temperatures and pressures, making aluminium bronze a suitable choice. Additionally, the electrical conductivity of aluminium bronze makes it a valuable material for electrical connectors and switchgear.

In the architectural realm, aluminium bronze is increasingly used for decorative cladding and fittings, combining both functionality and aesthetic appeal. Its resistance to tarnishing and corrosion ensures that architectural components maintain their beauty over time.

Conclusion

In summary, aluminium bronze casting presents a multitude of advantages, including exceptional durability, corrosion resistance, and casting versatility. With its wide range of applications across various industries, aluminium bronze continues to be a critical material in the manufacturing of high-performance components. As technology advances and the demand for innovative materials grows, aluminium bronze will undoubtedly play a pivotal role in shaping the future of casting and manufacturing processes.

-

Why Is Choosing the Right Motor Housing Critical for Engine Performance?NewsJul.18,2025

-

Which Impeller Types Best Optimize Your Pump’s Efficiency?NewsJul.18,2025

-

Optimize Maintenance Efficiency with Durable Oil Catch SolutionsNewsJul.18,2025

-

Maximize Pump Performance with Precision-Engineered ComponentsNewsJul.18,2025

-

Elevate Industrial Flow Systems with Precision-Engineered ComponentsNewsJul.18,2025

-

Boost Durability and Functionality with Precision Power CastingsNewsJul.18,2025