Mobile:+86-311-808-126-83

Email:info@ydcastings.com

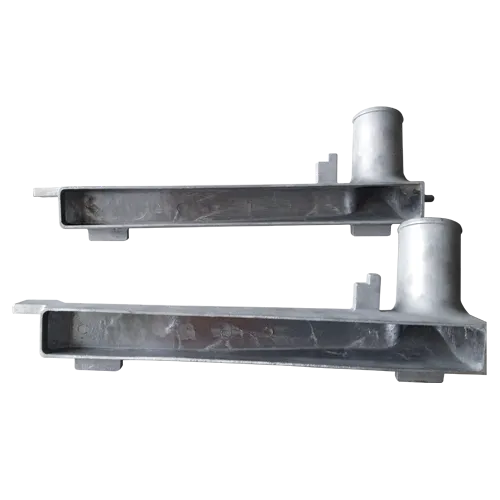

7 pipe cap

Understanding 7% Pipe Cap A Comprehensive Overview

In the world of industrial piping systems, various components are essential for maintaining the integrity and efficiency of fluid transportation systems. Among these components, pipe caps play a crucial role, and the 7% pipe cap is no exception. In this article, we will explore what a 7% pipe cap is, its applications, benefits, and the significance of understanding this component in various industries.

What is a Pipe Cap?

A pipe cap is a fitting used to cover the end of a pipe. It is designed to seal the pipe's end to prevent contamination, avoid leakage, and stop the flow of liquids or gases. Pipe caps come in different shapes, sizes, and materials, depending on their specific application. The term 7% pipe cap typically refers to a specific dimension or characteristic of the cap in relation to the pipe it is intended for.

The Importance of the 7% Specification

The designation of 7% in a pipe cap usually relates to the cap's fitting characteristics or its material thickness. When it comes to piping systems, the dimensions and tolerances specified can greatly impact the system's overall performance. A 7% designation might imply that the cap has a fitting or wall thickness that provides a balance between strength and cost-efficiency. This specification is particularly important in scenarios where pressure build-up is a concern, such as in chemical processing plants or oil and gas transportation.

Applications of 7% Pipe Caps

The 7% pipe cap finds its applications across various industries, including

1. Oil and Gas In the oil and gas sector, pipe caps are critical for isolating sections of piping systems during maintenance or emergency situations. The 7% cap ensures that high-pressure contents are securely contained, providing safety and reliability.

2. Chemical Processing Chemical facilities often require robust sealing solutions to prevent chemical leaks. A 7% pipe cap, typically crafted from corrosion-resistant materials, can protect the integrity of the pipeline while ensuring compliance with safety regulations.

7 pipe cap

3. Water Supply and Wastewater Management In municipal water systems, caps are used to seal pipes during installation or repair. The 7% specification allows for a solid connection that can withstand the necessary pressure and potential environmental challenges.

4. Construction In construction projects, pipe caps are used for temporary sealing during installation. The 7% caps provide a reliable option for securing pipes until the system is fully operational.

Benefits of Using 7% Pipe Caps

Choosing a 7% pipe cap offers several advantages

- Reliability With a specification that allows for robust performance, these caps can withstand high pressure and resist leaks effectively. - Cost-Efficiency The balance of strength and cost associated with the 7% cap means that organizations can rely on a durable solution without overspending on materials.

- Versatility The diverse applications across multiple industries render the 7% pipe cap a versatile choice for various projects, simplifying inventory management for suppliers and contractors.

- Safety Ensuring that the pipeline is securely capped reduces the risk of accidents and spills, promoting a safer working environment.

Conclusion

The 7% pipe cap plays a vital role in the maintenance and functionality of various piping systems. Understanding its specifications, applications, and benefits is essential for professionals in the industry. Whether it is in oil and gas, chemical processing, or water treatment, selecting the right pipe cap can make a significant difference in the overall performance of a piping system. As industries continue to evolve, the importance of reliable and safe piping components like the 7% pipe cap cannot be overstated.

-

Impeller Technology That Powers Precision in Pump SystemsNewsMay.22,2025

-

Valve Durability Begins with Quality Cast Iron ComponentsNewsMay.22,2025

-

Performance Cooling with Advanced Automobile Water Pump SolutionsNewsMay.22,2025

-

How Motor Housing and Oil Pans Shape Engine PerformanceNewsMay.22,2025

-

How Metal Castings Drive Modern Manufacturing EfficiencyNewsMay.22,2025

-

Exploring the Engineering Behind Valve Body CastingsNewsMay.22,2025