Mobile:+86-311-808-126-83

Email:info@ydcastings.com

Understanding the Specifications and Uses of 7 8% Pipe Caps for Plumbing Systems

The Importance of 7 8% Pipe Cap in Industrial Applications

In the realm of industrial piping systems, the significance of pipe fittings cannot be overstated. Among the multitude of fittings available, the 7 8% pipe cap stands out for its unique design and functionality. Understanding the characteristics and uses of this specific type of pipe cap is crucial for engineering professionals and industrial operators alike.

The Importance of 7 8% Pipe Cap in Industrial Applications

One of the primary features of the 7 8% pipe cap is its ability to withstand high pressure and temperature, making it suitable for use in extreme conditions. Industries such as oil and gas, chemical processing, and water treatment require reliable and robust fittings. The 7 8% pipe cap is designed to meet these demands, ensuring the integrity of the piping system and safeguarding against potential leaks or failures. This reliability not only enhances operational efficiency but also mitigates safety risks associated with hazardous materials.

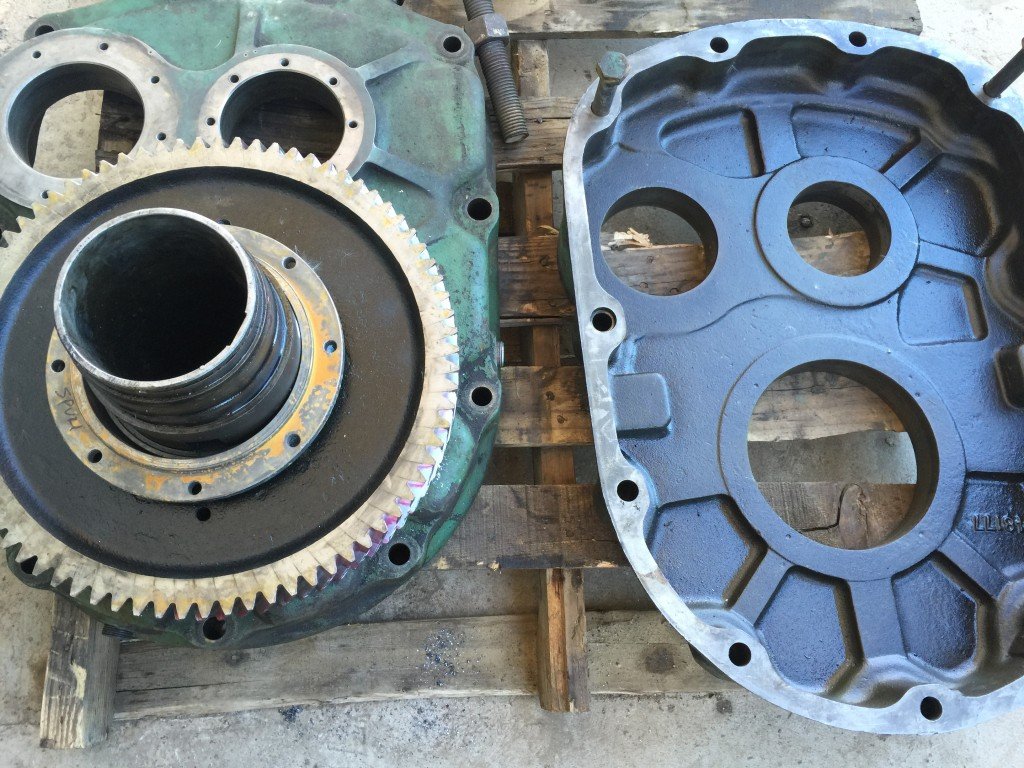

7 8 pipe cap

Moreover, the installation of a pipe cap like the 7 8% is relatively straightforward, which is an added benefit for industrial operations. It allows for quick modifications to existing pipeline configurations, enabling maintenance teams to efficiently manage their systems. The ease of installation helps minimize downtime, ensuring that production processes remain uninterrupted.

The versatility of the 7 8% pipe cap extends beyond just sealing. In many applications, it can also serve as an access point for inspection or cleaning, contributing to the overall maintenance strategy of a facility. This dual functionality is invaluable, particularly in industries where regular checks and balances are mandatory to comply with safety regulations.

Another essential aspect to consider is the economic impact of using high-quality pipe fittings like the 7 8% cap. Investing in reliable components reduces the likelihood of failures, thus avoiding costly repairs and operational interruptions. By selecting durable and efficient fittings, businesses can achieve long-term savings while maintaining optimal performance.

In conclusion, the 7 8% pipe cap is a pivotal component in the construction and maintenance of industrial piping systems. Its ability to provide reliable sealing under various conditions, ease of installation, and dual functionality for maintenance purposes makes it indispensable. Companies that prioritize the use of such quality components not only enhance their operational efficiency but also ensure the safety and longevity of their systems. As industries continue to evolve, the importance of dependable fittings like the 7 8% pipe cap will only grow, emphasizing the need for continuous investment in quality materials and equipment.

-

Understanding Metal Casting TechniquesNewsApr.02,2025

-

Understanding Exhaust Manifolds for Enhanced Engine PerformanceNewsApr.02,2025

-

The World of Metal FabricationNewsApr.02,2025

-

Key Components for Pump and Turbo EfficiencyNewsApr.02,2025

-

Essential Tools for Automotive Maintenance and RepairNewsApr.02,2025

-

Durable Valve Components for Effective Water ManagementNewsApr.02,2025