Mobile:+86-311-808-126-83

Email:info@ydcastings.com

6-Inch Pipe Cap for Secure and Durable Piping Solutions

Understanding the 6-Inch Cap for Pipe Applications

In the world of plumbing and piping, the specifications and components used can greatly influence the efficiency, safety, and reliability of fluid transport systems. Among various fittings, the 6-inch cap for pipes stands out as a crucial component for sealing the ends of pipes with a 6-inch diameter. This article delves into the features, benefits, and applications of 6-inch caps in piping systems.

Features of a 6-Inch Cap

A 6-inch cap is designed to fit securely over the end of a 6-inch diameter pipe. Typically made from materials such as PVC (Polyvinyl Chloride), CPVC (Chlorinated Polyvinyl Chloride), or metal (such as steel or brass), these caps serve multiple purposes. The selection of material often depends on the application's requirements such as pressure, temperature, and the type of fluid being transported.

1. Material Varieties - PVC Caps Lightweight and resistant to corrosion, making them ideal for drainage systems and chemical processing. - Metal Caps Often used in oil and gas applications due to their strength and high-temperature tolerance. Metal caps can handle more pressure compared to plastic versions. - CPVC Caps Suitable for hot water applications, as CPVC can withstand higher temperatures than PVC.

2. Dimensions and Compatibility - The standard 6-inch cap has an outer diameter slightly larger than 6 inches, allowing it to fit snugly without leaking. - It is also available in various designs, including threaded, slip-on, and socket adaptors, to accommodate different types of pipe connections.

Benefits of Using a 6-Inch Cap

Using caps in piping systems offers numerous advantages

1. Sealing and Protection The primary function of a 6-inch cap is to seal the open end of a pipe, preventing debris from entering and protecting the internal surfaces from corrosion and damage. This is especially critical in outdoor applications where exposure to environmental elements can lead to pipe degradation.

2. Pressure Management By capping the ends of pipes, the integrity of pressurized systems is maintained. This is crucial in systems transporting water, gas, or other fluids under pressure, as leaks can lead to significant safety hazards and financial losses.

3. System Maintenance and Modifications Caps allow for easy maintenance and future modifications to piping systems. When repairs are needed, or modifications must be made, caps can be easily removed to access the pipe interior without cutting the pipe itself.

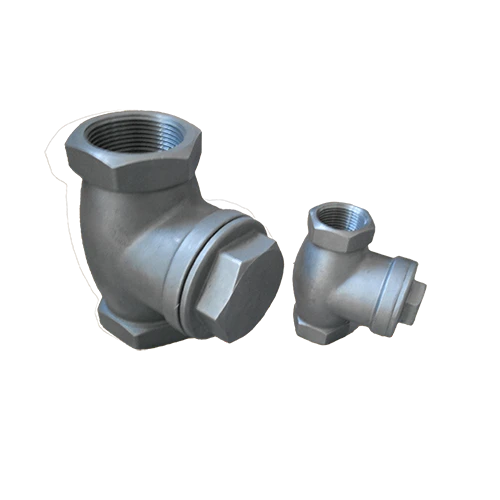

6 inch cap for pipe

4. Cost-Effectiveness Implementing caps can be a cost-effective solution for managing piping systems. The initial investment in caps is relatively low compared to the potential costs associated with repairs from leaks or system failures.

Applications of 6-Inch Caps

6-inch caps can be found across a multitude of industries, each with unique specifications and needs

1. Water Supply Systems In municipal and residential water supply systems, caps are routinely used in distribution lines to prevent contamination and allow for controlled maintenance.

2. Drainage and Wastewater In drainage systems, 6-inch caps help seal off sections of pipe, allowing for inspections and maintenance while preventing foul odors and gases from escaping.

3. Industrial Processing Industries handling chemicals or hazardous materials often utilize 6-inch caps to secure pipe ends and maintain safety protocols while also ensuring compliance with environmental regulations.

4. Oil and Gas In the oil and gas sector, 6-inch caps are commonly used to seal ends of pipelines until other connections can be made, helping to manage pressure and maintain safety within the system.

5. Construction During the construction of new pipelines, temporary caps may be used until the system is completed and can be extended or branched out.

Conclusion

In conclusion, the 6-inch cap for pipes serves as a fundamental component in various piping systems, providing sealing, protection, and accessibility. Its diverse applications across numerous industries reflect its importance in ensuring the reliability and integrity of fluid transport systems. Understanding the features, benefits, and uses of these caps can help stakeholders make informed decisions regarding their piping needs, ensuring optimal performance and safety in their operations. Whether for a simple residential plumbing project or complex industrial applications, a 6-inch cap is an invaluable asset in the realm of piping solutions.

-

Understanding Metal Casting TechniquesNewsApr.02,2025

-

Understanding Exhaust Manifolds for Enhanced Engine PerformanceNewsApr.02,2025

-

The World of Metal FabricationNewsApr.02,2025

-

Key Components for Pump and Turbo EfficiencyNewsApr.02,2025

-

Essential Tools for Automotive Maintenance and RepairNewsApr.02,2025

-

Durable Valve Components for Effective Water ManagementNewsApr.02,2025