Mobile:+86-311-808-126-83

Email:info@ydcastings.com

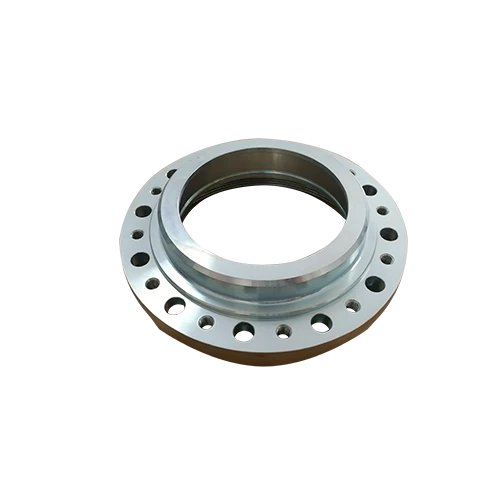

68mm end cap

Understanding the Importance of 68mm End Caps in Various Applications

End caps are essential components in various industries, providing vital functions and ensuring the integrity of systems. Among the many sizes and types available, the 68mm end cap stands out due to its versatility and widespread usage. This article explores the significance of 68mm end caps, their applications, and the materials commonly used in their production.

A 68mm end cap serves as a cover or seal for pipes, tubes, and other cylindrical structures. These caps play a crucial role in preventing contamination, maintaining pressure, and ensuring the smooth operation of systems. The 68mm size offers a perfect fit for a variety of standard pipes, making it a highly sought-after component in plumbing, construction, and manufacturing industries.

One of the primary applications of 68mm end caps is in plumbing systems

. They are used to close the ends of pipes, thus preventing water leakage and ensuring that the flow remains directed in the intended path. This feature is critical in both residential and commercial plumbing applications, where water damage can result in costly repairs and disruptions. Additionally, 68mm end caps can be employed in drainage systems to keep debris out and maintain optimal water flow.68mm end cap

In the field of construction, these end caps are often used to seal off steel, PVC, or other types of pipes that may be exposed to elements or physical stress. This sealing protects the pipe from environmental damage, corrosion, and potential hazards. Furthermore, in manufacturing processes, 68mm end caps can serve as protective covers during shipping and handling, preventing damage to the internal components of machinery and equipment.

The material of the end caps is equally crucial. Common materials include PVC, CPVC, stainless steel, and aluminum. Each material offers unique benefits—PVC is lightweight and resistant to corrosion, while stainless steel provides durability and strength. The choice of material often depends on the specific application requirements, such as temperature tolerance, pressure handling, and environmental factors.

In addition to their practical applications, 68mm end caps can also be customized to meet specific needs. Many manufacturers offer options for different colors, thread types, and finishes, allowing for tailored solutions in various projects. This customization ensures that end caps not only perform effectively but also integrate seamlessly with existing systems.

In conclusion, the 68mm end cap is more than just a simple component; it is vital in enhancing the functionality and safety of various systems. Its wide array of applications—from plumbing to construction and manufacturing—along with the possibility of customization, makes it an essential part of many industries. Understanding the importance of these caps can lead to better decision-making in choosing the right components for specific projects, ultimately contributing to the efficiency, safety, and durability of the systems in which they are used.

-

Why Should You Invest in Superior Pump Castings for Your Equipment?NewsJun.09,2025

-

Unlock Performance Potential with Stainless Impellers and Aluminum End CapsNewsJun.09,2025

-

Revolutionize Your Machinery with Superior Cast Iron and Aluminum ComponentsNewsJun.09,2025

-

Revolutionize Fluid Dynamics with Premium Pump ComponentsNewsJun.09,2025

-

Optimizing Industrial Systems with Essential Valve ComponentsNewsJun.09,2025

-

Elevate Grid Efficiency with High-Precision Power CastingsNewsJun.09,2025