Mobile:+86-311-808-126-83

Email:info@ydcastings.com

Versatile Applications of 304 Stainless Steel Casting in Various Industries

Understanding 304 Stainless Steel Casting

304 stainless steel, a widely recognized grade of stainless steel, is known for its impressive corrosion resistance, formability, and durability. As one of the most commonly used alloys in the industry, 304 stainless steel casting plays a pivotal role in various applications across multiple sectors, including aerospace, automotive, food processing, and chemical industries.

Composition and Properties of 304 Stainless Steel

The primary constituents of 304 stainless steel are iron, chromium (18%), and nickel (8%). This unique combination of elements gives 304 its exceptional corrosion resistance, particularly in environments exposed to acidic and alkaline solutions. The high nickel content enhances its ductility and toughness, making it ideal for applications that require significant bending and manipulation without breaking.

One of the most notable characteristics of 304 stainless steel is its excellent resistance to oxidation and scaling at elevated temperatures. Additionally, it exhibits good weldability, meaning it can be easily shaped and joined without compromising its structural integrity. These properties make 304 stainless steel casting a preferred choice for manufacturing components that require strength and durability in harsh environments.

The Casting Process

Casting is a manufacturing process that involves pouring molten metal into a mold to create a specific shape. The process begins with melting the 304 stainless steel in a furnace until it reaches a liquid state. Once molten, the steel is poured into a pre-formed mold that defines the final shape of the desired product. After the steel cools and solidifies, the mold is removed, revealing the finished cast item.

304 stainless steel casting

There are several methods for casting 304 stainless steel, including sand casting, investment casting, and lost-wax casting. Each method has its unique advantages depending on the shape, size, and complexity of the component being produced. For instance, investment casting is excellent for creating intricate designs with tight tolerances, while sand casting is more suitable for larger, simpler components.

Applications of 304 Stainless Steel Castings

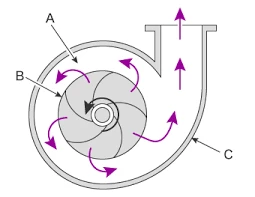

304 stainless steel castings are used in a diverse range of applications due to their versatility and strength. In the food and beverage industry, equipment made from 304 stainless steel is essential for maintaining hygiene and preventing contamination. Items like tanks, valves, and pumps are commonly manufactured using this grade because it meets strict safety and cleanliness standards.

In the chemical industry, 304 stainless steel's resistance to corrosive substances makes it a preferred choice for various processing equipment, including reactors and storage tanks. Additionally, its ability to withstand high temperatures allows for safe operation in environments where other materials might fail.

The aerospace and automotive sectors also utilize 304 stainless steel castings for parts that require high strength-to-weight ratios. Components like brackets, housings, and engine parts benefit from the alloy's durability, ensuring longevity and reliability under extreme conditions.

Conclusion

304 stainless steel casting is a cornerstone of modern manufacturing, providing essential advantages in strength, durability, and resistance to corrosion and high temperatures. Its versatility makes it a suitable choice for a wide array of applications across various industries. As technology advances and new alloys are developed, the fundamentals of 304 stainless steel will continue to play an integral role in the production of high-quality, reliable components that meet the demands of diverse industrial applications. By understanding the properties and benefits of 304 stainless steel casting, manufacturers can make informed decisions to enhance their production capabilities and ultimately improve the performance of their products.

-

Why Should You Invest in Superior Pump Castings for Your Equipment?NewsJun.09,2025

-

Unlock Performance Potential with Stainless Impellers and Aluminum End CapsNewsJun.09,2025

-

Revolutionize Your Machinery with Superior Cast Iron and Aluminum ComponentsNewsJun.09,2025

-

Revolutionize Fluid Dynamics with Premium Pump ComponentsNewsJun.09,2025

-

Optimizing Industrial Systems with Essential Valve ComponentsNewsJun.09,2025

-

Elevate Grid Efficiency with High-Precision Power CastingsNewsJun.09,2025