Mobile:+86-311-808-126-83

Email:info@ydcastings.com

3/4 Copper End Cap - Durable Plumbing Solutions

The Importance of 3% and 4% Copper End Caps in Modern Applications

Copper end caps are essential components in various industries, primarily due to their excellent thermal and electrical conductivity. Among the various compositions available, 3% and 4% copper end caps have gained significant attention for their unique properties and wide-ranging applications. These end caps not only serve functional purposes but also contribute to the overall efficiency and performance of the systems they are integrated into.

Composition and Properties

The designation of 3% and 4% copper typically refers to the percentage of alloying elements added to pure copper. For instance, a copper end cap containing 3% or 4% other metals, such as nickel or zinc, enhances the mechanical strength and corrosion resistance of the copper without compromising its excellent conductivity. This makes these end caps particularly suitable for demanding environments, such as those found in marine applications, electrical systems, and industrial manufacturing processes.

Moreover, alloys with higher copper content, such as 3% or 4%, exhibit improved fabricability. This means they can be easily shaped, welded, or soldered during the manufacturing process, allowing for versatility in design and installation. The enhanced properties of these copper end caps make them a preferred choice for engineers and designers looking to optimize their projects.

Applications

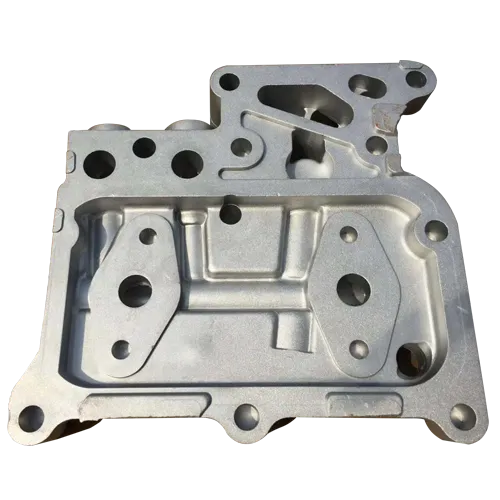

3 4 copper end cap

3% and 4% copper end caps are widely used in various applications, including plumbing, HVAC systems, and electrical conduits. In plumbing, these end caps are instrumental in sealing pipe ends, preventing water leakage and ensuring system integrity. Their corrosion-resistant characteristics allow them to withstand the harsh conditions often associated with water distribution systems.

In HVAC (Heating, Ventilation, and Air Conditioning) systems, the thermal conductivity of copper end caps ensures efficient heat transfer, optimizing the performance of heating and cooling units. Furthermore, their ability to withstand high pressures and temperatures makes them a critical component in these systems.

Electricians also favor 3% and 4% copper end caps for their projects. The high conductivity of these alloys makes them ideal for connecting wires and cables, ensuring minimal energy loss and enhancing electrical efficiency.

Conclusion

In conclusion, 3% and 4% copper end caps are indispensable components in modern applications across a variety of industries. Their unique properties, including enhanced mechanical strength, corrosion resistance, and excellent conductivity, make them a reliable choice for plumbing, HVAC, and electrical systems. As technology evolves, the demand for these specialized end caps is expected to grow, further emphasizing their critical role in supporting infrastructure and industrial applications. Incorporating these innovative materials can lead to improved system performance and longevity, ultimately contributing to a more efficient and sustainable future.

-

Why Should You Invest in Superior Pump Castings for Your Equipment?NewsJun.09,2025

-

Unlock Performance Potential with Stainless Impellers and Aluminum End CapsNewsJun.09,2025

-

Revolutionize Your Machinery with Superior Cast Iron and Aluminum ComponentsNewsJun.09,2025

-

Revolutionize Fluid Dynamics with Premium Pump ComponentsNewsJun.09,2025

-

Optimizing Industrial Systems with Essential Valve ComponentsNewsJun.09,2025

-

Elevate Grid Efficiency with High-Precision Power CastingsNewsJun.09,2025