Mobile:+86-311-808-126-83

Email:info@ydcastings.com

150mm End Cap for Piping Systems and Tubing Applications

Understanding the Importance of 150mm End Caps

End caps play a crucial role in various industries, from plumbing and construction to automotive and manufacturing. One specific type that has gained attention is the 150mm end cap. This article explores the significance of 150mm end caps, their applications, and the benefits they offer.

What is a 150mm End Cap?

A 150mm end cap is a type of fitting designed to seal the open end of a pipe or tube with a 150mm diameter. These caps are typically used in piping systems to prevent contamination, leakage, and the ingress of foreign objects. Made from various materials, such as PVC, stainless steel, or aluminum, these end caps are versatile and cater to different environmental conditions and requirements.

Applications of 150mm End Caps

1. Plumbing Systems In residential and commercial plumbing, 150mm end caps are used to terminate water supply lines or drainage systems. This helps maintain system integrity by preventing backflow and ensuring clean water supply.

2. Construction In construction projects, these end caps may be used to seal temporary piping systems or to cap off unused pipe sections. This not only ensures safety on construction sites but also aids in compliance with local regulations regarding plumbing and drainage.

3. HVAC Systems In heating, ventilation, and air conditioning (HVAC) applications, 150mm end caps are utilized to close off ductwork, ensuring proper airflow and maintaining system efficiency.

4. Industrial Uses Industries often use these caps in various processes, including chemical handling or fluid transport. The cap helps in maintaining system pressure and preventing any hazardous materials from escaping.

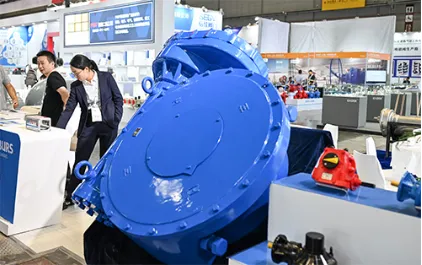

150mm end cap

Benefits of Using 150mm End Caps

- Leak Prevention One of the main benefits of using end caps is the prevention of leaks. A well-fitted end cap can effectively seal off open pipe ends, ensuring that fluids remain contained within the system.

- Durability Most 150mm end caps are made from materials that resist corrosion and damage, ensuring a long life in various environments. This durability reduces the need for frequent replacements, ultimately saving costs.

- Ease of Installation Many end caps are designed for quick and easy installation, allowing for a seamless integration into existing systems. This is particularly beneficial in time-sensitive projects where efficiency is key.

- Versatility in Material Depending on the application, one can choose from a variety of materials, each offering unique advantages. For instance, PVC caps are lightweight and resistant to corrosion, while stainless steel caps provide durability in high-pressure applications.

- Cost-Effectiveness While the initial investment in quality end caps might be higher, their durability and effectiveness in preventing leaks and breakages can lead to significant cost savings in the long run.

Conclusion

In conclusion, 150mm end caps are essential components in various piping and duct systems across multiple industries. Their primary function of sealing open pipe ends provides numerous advantages, such as leak prevention, durability, and ease of installation. Whether in plumbing, construction, HVAC, or industrial applications, incorporating 150mm end caps can enhance system performance and contribute to the overall safety and efficiency of operations. As industries continue to evolve, the demand for reliable and effective fittings like the 150mm end cap will undoubtedly remain strong, underscoring their importance in modern engineering and construction practices.

-

Why Should You Invest in Superior Pump Castings for Your Equipment?NewsJun.09,2025

-

Unlock Performance Potential with Stainless Impellers and Aluminum End CapsNewsJun.09,2025

-

Revolutionize Your Machinery with Superior Cast Iron and Aluminum ComponentsNewsJun.09,2025

-

Revolutionize Fluid Dynamics with Premium Pump ComponentsNewsJun.09,2025

-

Optimizing Industrial Systems with Essential Valve ComponentsNewsJun.09,2025

-

Elevate Grid Efficiency with High-Precision Power CastingsNewsJun.09,2025