Mobile:+86-311-808-126-83

Email:info@ydcastings.com

1 inch 2 inch pipe closing cap for secure and durable pipe sealing solution

Understanding the Importance of 1% 202% Inch Pipe End Caps

In the world of piping systems, the use of pipe end caps plays a crucial role in ensuring the integrity and functionality of various applications. Among the myriad of options available, the 1% 202% inch pipe end cap stands out for its specific dimensions and high-quality materials, making it an essential component in plumbing, industrial, and fluid management processes.

What is a Pipe End Cap?

A pipe end cap is a fitting that is used to seal the end of a pipe, effectively closing it off. This is particularly important in systems where the flow of liquids or gases needs to be contained, or where the termination of a pipeline is necessary. End caps can be found in various sizes and materials, depending on the application requirements, and they provide several critical functions, such as preventing contamination, protecting against corrosion, and maintaining pressure within the system.

The Significance of 1% 202% Inch Pipe End Caps

The designation of 1% 202% inch typically refers to a specific nominal dimension that follows industry standards. Although the phrasing might suggest a typographical error, it implies an attention to precision and detail that is essential in engineering applications. Pipe fittings, such as end caps, need to be fabricated to exact measurements to ensure a snug fit and a reliable seal.

The 1% 202% inch pipe end cap can be used in both residential and commercial applications, serving a variety of functions - Capping Off Unused Outlets In plumbing systems, these end caps can close off outlets that are no longer needed, thereby preventing leaks and maintaining pressure in the pipeline. - Maintenance and Repair During maintenance operations, end caps provide a temporary solution to seal a section of pipe to ensure that repairs can be conducted without losing pressure or exposing the system to the external environment. - Fluid Dynamics In fluid systems, controlling the flow is paramount. Pipe end caps help redirect flow or terminate lines in a manner that assists in maintaining system efficiency.

1 2 inch pipe end cap

Material Considerations

Pipe end caps are made from various materials, including PVC, stainless steel, and carbon steel, each offering different benefits. For instance, stainless steel end caps are preferred in environments where corrosion resistance is critical, while PVC caps are lightweight and easier to work with in less demanding applications. The choice of material often depends on factors such as the type of medium being transported, operating temperatures, and pressure conditions.

Installation and Maintenance

Installing a pipe end cap is typically straightforward, requiring minimal tools. It is essential to follow manufacturer guidelines to ensure an effective seal and appropriate compatibility with the existing piping system. Regular inspection and maintenance should be conducted to check for signs of wear or leaks, ensuring long-term performance and preventing unexpected failures.

Conclusion

In summary, the 1% 202% inch pipe end cap is a vital component in various piping systems, allowing for the effective sealing of pipe ends. By understanding the importance, functionality, and material options of these fittings, professionals in plumbing and fluid management can ensure the integrity and efficiency of their systems. Whether for domestic use or industrial applications, the correct use of pipe end caps is essential in safeguarding against leaks and maintaining system performance.

-

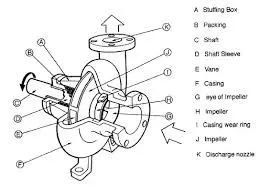

Impeller Technology That Powers Precision in Pump SystemsNewsMay.22,2025

-

Valve Durability Begins with Quality Cast Iron ComponentsNewsMay.22,2025

-

Performance Cooling with Advanced Automobile Water Pump SolutionsNewsMay.22,2025

-

How Motor Housing and Oil Pans Shape Engine PerformanceNewsMay.22,2025

-

How Metal Castings Drive Modern Manufacturing EfficiencyNewsMay.22,2025

-

Exploring the Engineering Behind Valve Body CastingsNewsMay.22,2025