Mobile:+86-311-808-126-83

Email:info@ydcastings.com

Understanding the Features and Benefits of 12 Inch Pipe Caps for Your Projects

Understanding the Importance of 12-Inch Pipe Caps in Plumbing and Construction

In the realm of plumbing and construction, the importance of pipe fittings cannot be overstated. Amongst the various types of fittings, the 12-inch pipe cap plays a vital role in ensuring the integrity and functionality of piping systems. This article aims to shed light on the significance, uses, and considerations associated with 12-inch pipe caps.

What is a Pipe Cap?

A pipe cap is a fitting that is used to seal the end of a pipe. It is designed to provide a closure for the open ends of piping systems, effectively preventing the escape of fluids and maintaining pressure within the system. Pipe caps come in various sizes, materials, and shapes, with the 12-inch pipe cap being a common choice in both residential and industrial applications.

Uses of 12-Inch Pipe Caps

The 12-inch pipe cap is widely utilized in various sectors, ranging from residential plumbing to large-scale industrial operations

. Here are some of the primary applications1. Sealing and Protection One of the primary uses of the 12-inch pipe cap is to seal the ends of pipes that are not in use. This sealing prevents debris and contaminants from entering the pipes and protects the internal surfaces from corrosion and degradation.

2. Future Expansion In many installations, especially in industrial settings, pipe systems are designed with future expansion in mind. Using a 12-inch pipe cap allows for easy access to the system later, permitting the addition of new sections without significant alterations.

3. Pressure Maintenance In systems that operate under pressure, such as water supply lines or gas pipelines, a pipe cap is critical for maintaining the necessary pressure. It acts as a sturdy barrier that can withstand the operational pressures of the system.

4. Safety Regulations Many industries operate under strict safety regulations. The use of 12-inch pipe caps helps to meet these regulations by providing a secure closure, thereby minimizing the risk of leaks and potential hazardous situations.

Materials of Pipe Caps

Pipe caps are manufactured from several materials, depending on the application and the specific requirements of the system. Common materials include

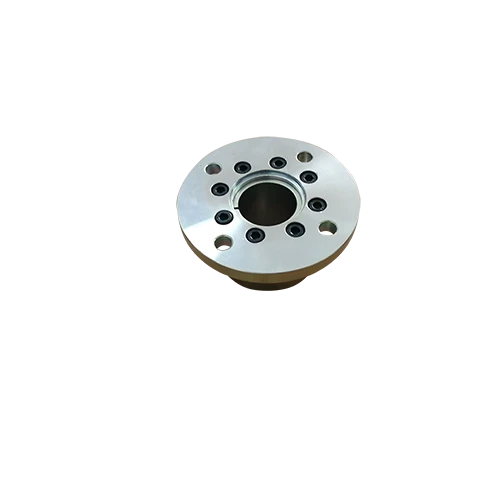

12 inch pipe cap

- PVC (Polyvinyl Chloride) Lightweight and resistant to corrosion, PVC pipe caps are ideal for plumbing applications, especially for transporting water and other fluids.

- Carbon Steel For high-pressure systems, carbon steel pipe caps offer durability and strength. They are often used in industrial applications, oil and gas lines, and other heavy-duty environments.

- Stainless Steel Known for its resistance to corrosion and high temperatures, stainless steel pipe caps are essential in industries such as food processing and pharmaceuticals where hygiene is paramount.

Considerations When Choosing a 12-Inch Pipe Cap

Selecting the right pipe cap involves several considerations to ensure it meets the specific needs of your project. Here are key factors to evaluate

1. Material Compatibility The material of the cap should be compatible with the fluid transported in the pipes. For instance, corrosive materials may require a cap made of stainless steel or specific coatings on carbon steel.

2. Pressure Rating Ensure that the chosen cap can withstand the operational pressure of the pipe system. Each material has different pressure ratings, so it’s crucial to select one that aligns with your requirements.

3. Installation Ease Consider how easy it is to install the cap. Some caps may require welding, while others can be screwed on. Understanding your installation process can help in choosing the right type of cap.

4. Cost While it’s important to ensure you meet the quality requirements, budgeting for materials is also essential. Prices can vary significantly based on material and manufacturer, so it’s advisable to explore multiple options.

Conclusion

In summary, the 12-inch pipe cap is an essential component in plumbing and construction. Its ability to seal, protect, and maintain pressure makes it invaluable across various applications. By understanding the uses, materials, and considerations involved in selecting a pipe cap, professionals can ensure efficient and safe piping systems. As infrastructures continue to evolve and expand, the importance of quality fittings like the 12-inch pipe cap will only grow, underscoring the need for informed decision-making in materials selection.