Mobile:+86-311-808-126-83

Email:info@ydcastings.com

French

Stainless Steel Casting: Precision & Corrosion-Resistant Metal Parts

Mastering Industrial Precision: The Power of stainless steel casting

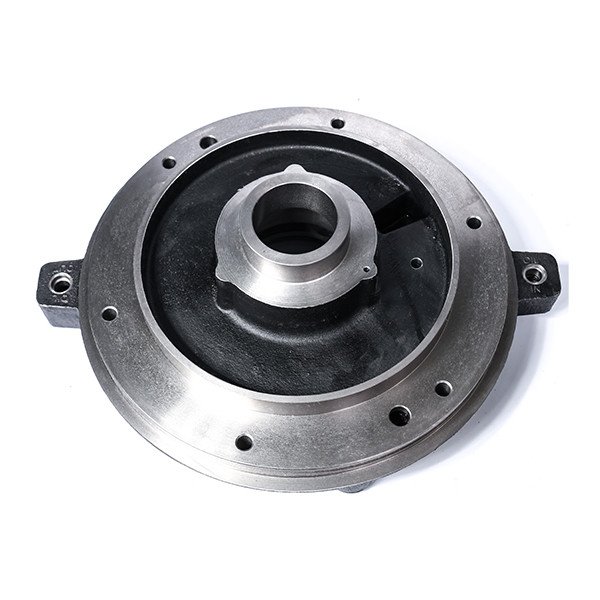

In the demanding landscape of modern industrial engineering, the integrity and performance of components are paramount. This is where stainless steel casting emerges as a critical manufacturing process, delivering unparalleled durability, corrosion resistance, and precision for a vast array of applications. The market for high-quality metal components is witnessing robust growth, driven by escalating demands in sectors like petrochemical, metallurgy, and water treatment, all of which require parts capable of withstanding extreme conditions. Components such as the Cooling Flange Lower and Bearing Housing Lower, essential for critical machinery, exemplify the need for materials that offer longevity and operational efficiency. The inherent properties of stainless steel, coupled with advanced casting techniques, ensure that these parts meet the stringent performance criteria of sophisticated industrial systems, minimizing downtime and maintenance costs across their operational lifespan.

Beyond its inherent material advantages, the adoption of advanced casting technologies signifies a major trend in the manufacturing sector. Industries are increasingly seeking suppliers who can provide not only standard components but also highly customized solutions that integrate seamlessly into complex mechanical assemblies. The ability to produce intricate geometries with high dimensional accuracy is a hallmark of superior stainless steel casting, making it a preferred choice over traditional fabrication methods. This commitment to precision and adaptability directly translates into enhanced energy efficiency and superior anti-corrosion properties in the end products, offering significant operational advantages for B2B decision-makers focused on long-term investment returns. The continuous innovation in casting techniques, combined with stringent quality controls, positions stainless steel castings as a cornerstone for future industrial development.

The Unrivaled Advantages and Applications of Stainless Steel Castings

The selection of materials and manufacturing processes is critical in engineering design, with stainless steel casting offering distinct benefits over alternatives like aluminum die casting or green sand metal casting. Stainless steel’s superior resistance to corrosion, high temperatures, and wear makes it ideal for harsh operating environments, extending the service life of components like the Cooling Flange Lower and Bearing Housing Lower. Unlike aluminum, which excels in lightweight applications but may lack the robust mechanical properties for heavy-duty industrial use, stainless steel provides exceptional tensile strength and creep resistance. This robust material is particularly suited for fluid handling systems in the petrochemical industry, high-pressure valves, and critical components in power generation, where material integrity is non-negotiable and failure could lead to catastrophic consequences.

Furthermore, the inherent anti-corrosion properties of stainless steel casting significantly reduce the need for protective coatings or frequent replacements, leading to lower lifecycle costs and improved sustainability. While green sand metal casting is a cost-effective method for certain applications, it often results in rougher surface finishes and less precise dimensions compared to the advanced methods employed for stainless steel. This precision is vital for components that require tight tolerances and superior surface quality to function efficiently, such as those used in precision machinery. The ability to achieve complex geometries with high accuracy directly enhances the functional performance of the final assembly, contributing to overall system efficiency and reducing energy consumption in the long run. The adaptability of stainless steel alloys also allows for tailoring properties to specific application requirements, providing a versatile solution for a broad spectrum of industrial challenges.

Comprehensive Manufacturing Process of Stainless Steel Casting

The manufacturing of high-quality stainless steel casting components involves a meticulous multi-stage process designed to ensure precision and material integrity. It typically begins with the creation of a wax pattern, which is an exact replica of the final component. This pattern is then coated with refractory slurry and sand, building up a robust shell. After the shell is cured, it undergoes a dewaxing process where the wax is melted out, leaving a hollow ceramic mold. Molten stainless steel, precisely heated to its casting temperature, is then poured into this preheated mold. This investment casting method, also known as lost-wax casting, is preferred for its ability to produce intricate shapes with exceptional dimensional accuracy and superior surface finishes, minimizing the need for extensive post-casting machining.

Following solidification, the ceramic shell is broken away (knockout), revealing the raw casting. Subsequent steps include cut-off to separate individual parts from the gating system, and initial grinding to remove any excess material. Heat treatment is then applied, which is crucial for optimizing the mechanical properties of the stainless steel, such as hardness, ductility, and strength, and for stress relief. Finally, components like the Cooling Flange Lower or Bearing Housing Lower often undergo precision CNC machining to achieve the extremely tight tolerances required for their specific applications. Throughout this entire process, rigorous inspection standards, including ISO 9001 and ANSI specifications, are meticulously followed. Non-destructive testing (NDT) methods like X-ray, ultrasonic, and magnetic particle inspection are employed to detect any internal defects, ensuring that every stainless steel casting component meets the highest quality and safety benchmarks before reaching the customer.

Key Technical Parameters and Material Specifications for Stainless Steel Casting

Understanding the technical specifications of stainless steel casting is essential for engineers and procurement specialists to ensure optimal performance in specific industrial applications. Different grades of stainless steel offer varying properties tailored to distinct requirements. For instance, AISI 304 (CF8) is highly versatile, offering excellent corrosion resistance and weldability, making it suitable for general industrial use and food processing. AISI 316 (CF8M) includes molybdenum, significantly enhancing its resistance to pitting and crevice corrosion, particularly in chloride environments, making it ideal for marine or chemical processing applications. Precipitation-hardening stainless steels like 17-4PH (CB7Cu-1) provide exceptional strength and hardness, often used in aerospace and high-stress components.

When considering components like the Cooling Flange Lower or Bearing Housing Lower, specific parameters such as surface finish, dimensional tolerances, and mechanical properties (tensile strength, yield strength, elongation, hardness) are critical. Investment casting typically achieves a surface roughness of Ra 3.2 to 6.3 µm and dimensional tolerances within ISO 8062-CT5 to CT7. The lifespan of a stainless steel casting component can extend for decades, often exceeding 20-30 years, depending on the application environment and proper maintenance. The table below details common stainless steel grades and their typical applications, providing a quick reference for material selection based on performance requirements and industry standards.

| Stainless Steel Grade | UNS/ASTM Designation | Key Characteristics | Typical Applications |

|---|---|---|---|

| 304 (CF8) | S30400 / A351 CF8 | Excellent corrosion resistance, good weldability, non-magnetic. | Food & beverage, general industrial, architectural. |

| 316 (CF8M) | S31600 / A351 CF8M | Superior resistance to pitting/crevice corrosion (molybdenum content), good for harsh environments. | Marine, chemical processing, pharmaceutical, medical. |

| 17-4PH (CB7Cu-1) | S17400 / A747 CB7Cu-1 | High strength, good corrosion resistance, excellent hardness, age-hardenable. | Aerospace, valves, shafts, gears, nuclear components. |

| 2205 (CD3MN) | S31803 / A928 CD3MN | Duplex stainless steel, high strength, excellent stress corrosion cracking resistance. | Oil & gas, desalination plants, pulp & paper. |

Diverse Applications Across Critical Industries

The versatility and robust characteristics of stainless steel casting make it indispensable across a multitude of critical industries. In the petrochemical sector, components such as specialized valves, pump housings, and pipeline fittings are cast from stainless steel to withstand highly corrosive chemicals, extreme temperatures, and high pressures, ensuring operational safety and efficiency. For the metallurgy industry, including steel mills and foundries, stainless steel castings are used in high-temperature processing equipment, providing durability against heat and abrasion. The inherent anti-corrosion properties significantly reduce maintenance costs and extend the lifespan of machinery in these harsh environments, contributing to substantial energy savings due to reduced downtime and consistent performance.

Furthermore, in the water supply and drainage sector, stainless steel is crucial for components like impellers, pump parts, and filter housings, where resistance to water, chlorine, and various effluents is paramount. Its non-leaching properties also make it safe for potable water systems. Beyond these, metal castings made from stainless steel find extensive use in marine applications for their saltwater corrosion resistance, in medical devices for their biocompatibility and ease of sterilization, and in food processing equipment where hygiene and resistance to cleaning agents are critical. Our expertise extends to producing high-precision components like the Cooling Flange Lower and Bearing Housing Lower that are engineered to excel in these specific demanding environments, ensuring reliable and energy-efficient performance for our B2B clients.

Manufacturer Comparison and Customization Solutions

Choosing the right manufacturing partner for stainless steel casting is a strategic decision that impacts product quality, delivery timelines, and overall project success. Key factors to consider include the manufacturer's demonstrated expertise in various casting methods, their range of material capabilities (e.g., beyond stainless steel, including aluminum die casting and aluminium metal casting), certifications like ISO 9001 and IATF 16949, and their capacity for producing both standard and highly customized components. A reputable manufacturer will possess advanced analytical tools and a deep understanding of metallurgy to advise on the optimal stainless steel grade and casting process for specific applications, ensuring the final product meets or exceeds performance expectations.

Customization is a cornerstone of our service offering, especially for intricate parts like the Cooling Flange Lower and Bearing Housing Lower. We specialize in working closely with clients from the design phase through to final production, offering rapid prototyping and design for manufacturability (DFM) services. This collaborative approach allows us to optimize designs for casting efficiency, minimize material waste, and achieve precise dimensional tolerances, crucial for components requiring seamless integration into complex systems. Our extensive experience in producing custom metal castings, including specialized aluminum casting die components, ensures that we can handle projects of varying complexities and scales, providing tailored solutions that translate into superior performance and cost-effectiveness for our B2B partners. Our commitment to innovation and client-specific solutions distinguishes us in the competitive casting market.

Trust and Reliability: Quality Assurance and Support

Building trust in the B2B sector for stainless steel casting relies heavily on unwavering commitment to quality assurance and comprehensive customer support. Our foundry adheres strictly to international standards such as ISO 9001, ensuring that every stage of production, from raw material inspection to final product verification, meets stringent quality benchmarks. This includes rigorous material testing, dimensional checks, and non-destructive testing (NDT) to guarantee that components like the Cooling Flange Lower and Bearing Housing Lower are free from defects and perform reliably under specified operating conditions. We provide detailed material certificates and test reports, offering full traceability and transparency for all our castings. Our extensive service years in the industry, marked by consistent delivery of high-quality metal castings, underscore our authoritative position and expertise.

Our commitment to our clients extends beyond delivery. We offer robust warranty commitments for all our products, providing peace of mind and demonstrating confidence in our manufacturing capabilities. Typical delivery lead times are optimized to meet project schedules, ranging from 4-6 weeks for tooling and samples, followed by 3-4 weeks for production batches, depending on complexity and volume. Our dedicated customer support team is available to address any technical queries, provide post-sales assistance, and facilitate ongoing communication. This holistic approach to client service ensures a seamless experience and fosters long-term partnerships. We also maintain a comprehensive FAQ section to address common concerns regarding design specifications, material properties, and order processing, further enhancing client confidence and clarity.

Frequently Asked Questions (FAQs) about Stainless Steel Casting:

- Q: What are the typical lead times for custom stainless steel castings?

A: Initial tooling and sample production typically take 4-6 weeks. Production runs usually follow within 3-4 weeks, depending on part complexity and order volume. - Q: What quality certifications do you hold?

A: We are ISO 9001 certified, ensuring our processes meet international quality management standards. Specific product certifications (e.g., for food contact or medical use) can be provided upon request. - Q: Can you help with the design of stainless steel casting components?

A: Yes, our engineering team offers comprehensive DFM (Design for Manufacturability) services, working with your designs to optimize them for casting efficiency, cost-effectiveness, and optimal performance. - Q: What types of testing do you perform on your castings?

A: We conduct various tests including chemical composition analysis, mechanical property testing (tensile, yield, hardness), dimensional inspection, and NDT (X-ray, ultrasonic, magnetic particle inspection) to ensure quality. - Q: What is the typical lifespan of a stainless steel casting?

A: With proper material selection and application, stainless steel castings can have an operational lifespan of 20-30 years or more, especially in non-abrasive or corrosive environments.

Conclusion: The Future of Industrial Precision with Stainless Steel Casting

The enduring demand for high-performance components in critical industrial applications firmly establishes stainless steel casting as an indispensable manufacturing technology. Its unparalleled combination of corrosion resistance, mechanical strength, and adaptability to complex geometries ensures that parts like the Cooling Flange Lower and Bearing Housing Lower operate with maximum efficiency and longevity. As industries continue to evolve, seeking more sustainable, energy-efficient, and reliable solutions, the role of advanced casting processes, particularly in stainless steel, will only grow. Partnering with a manufacturer that possesses deep expertise, adheres to rigorous quality standards, and offers comprehensive customization capabilities is paramount for success in today’s competitive global market.

We are committed to pushing the boundaries of what is possible in stainless steel casting, continuously investing in new technologies and refining our processes to meet the escalating demands of our B2B clients. Our focus remains on delivering components that not only meet but exceed performance expectations, contributing to the operational excellence and long-term success of your projects. Through precise engineering, meticulous quality control, and dedicated customer support, we stand as your trusted partner for all your industrial casting needs, driving innovation and reliability across diverse sectors.

References

- ASM International. (2008). ASM Handbook, Vol. 15: Casting. ASM International.

- Campbell, J. (2003). Castings Practice: The 10 Rules of Castings. Butterworth-Heinemann.

- Metals Handbook. (1990). Properties and Selection: Stainless Steels, Tool Materials and Special-Purpose Metals. ASM International.

- ISO 9001:2015. (2015). Quality management systems – Requirements. International Organization for Standardization.

- ASTM International. (Various Standards). Standard Specifications for Castings, Iron, and Steel. ASTM International.

-

Superior Aluminum Castings in Automotive Engine PartsNewsAug.22,2025

-

Common Materials Used in Fan Housing ManufacturingNewsAug.22,2025

-

Symptoms of a Stuck Automobile Water Pump ImpellerNewsAug.22,2025

-

The Importance of Valve Castings in Water TreatmentNewsAug.22,2025

-

Welding Techniques for End Cap Stainless Steel FittingsNewsAug.22,2025

-

How to Install a Water Pump Connector ProperlyNewsAug.22,2025