Mobile:+86-311-808-126-83

Email:info@ydcastings.com

French

Precision Metal Castings: Aluminum, Green Sand & Investment

The Foundational Role of metal castings in Modern Industry

In the intricate tapestry of modern manufacturing, metal castings stand as a cornerstone, providing the foundational components for a myriad of industries, from heavy machinery and automotive to delicate electronics and aerospace. The process of casting, fundamentally, involves pouring molten metal into a mold cavity of the desired shape, allowing it to solidify and take on that form. This ancient art has evolved dramatically over millennia, transitioning from primitive techniques to highly sophisticated, computer-controlled processes that enable the production of complex geometries with exceptional precision and metallurgical integrity. The versatility of metal castings lies in their ability to create parts that are robust, cost-effective, and often impossible to produce by other means, such as forging or machining alone. Industries requiring durable, high-performance components, often exposed to extreme conditions like high temperatures, corrosive environments, or immense pressures, invariably turn to cast solutions. The selection of the appropriate casting method and material is critical, dictated by the specific application's demands, including mechanical properties, surface finish requirements, dimensional tolerances, and economic viability. Our expertise at YD Castings spans the full spectrum of modern casting technologies, ensuring that each component not only meets but often exceeds the most stringent industry standards. We understand that the integrity of your final product hinges on the quality of its foundational parts, and our commitment to excellence in every phase of the casting process guarantees superior results. The inherent ability of casting to produce near-net-shape components significantly reduces material waste and subsequent machining, making it an environmentally conscious and economically advantageous manufacturing method in the long run.

The demand for high-performance metal castings continues to grow, driven by global megatrends such as sustainable energy initiatives, advancements in transportation, and the increasing complexity of industrial machinery. Whether it's the lightweighting efforts in the automotive sector through advanced aluminium metal casting or the high-strength, corrosion-resistant needs in the petrochemical industry satisfied by specialized alloys, metal castings are indispensable. The evolution of casting technologies, including improvements in mold materials, furnace design, and solidification modeling, has led to significantly enhanced control over microstructure and mechanical properties, pushing the boundaries of what is achievable. Modern casting operations incorporate advanced simulation software to predict metal flow, heat transfer, and solidification patterns, allowing engineers to optimize mold designs and process parameters before physical production even begins, thereby reducing prototyping costs and time-to-market. This integration of digital technology with traditional metallurgical expertise is what defines the cutting edge of the metal castings industry today. Furthermore, the emphasis on quality control has intensified, with non-destructive testing (NDT) methods like X-ray inspection, ultrasonic testing, and magnetic particle inspection becoming standard practices to ensure the internal integrity of cast components. This meticulous attention to detail at every stage of production reinforces the reliability and longevity of metal castings, making them the preferred choice for critical applications where failure is not an option. Our commitment to continuous improvement and adoption of these advanced techniques ensures that our metal castings are not just components, but critical enablers for your technological advancements.

Industry Trends and Technological Advancements in Metal Castings

The metal castings industry is currently undergoing a significant transformation, driven by several key trends aimed at improving efficiency, sustainability, and performance. One prominent trend is the increasing adoption of digital technologies, including Artificial Intelligence (AI) and Machine Learning (ML), for process optimization and predictive maintenance. These technologies enable foundries to analyze vast amounts of production data, identify correlations, and make real-time adjustments to casting parameters, leading to fewer defects, improved material utilization, and reduced energy consumption. For instance, AI-driven systems can predict potential porosity or shrinkage defects in complex metal castings by analyzing simulation results and historical production data, allowing engineers to modify gating systems or cooling rates proactively. This shift towards data-driven manufacturing significantly enhances the quality and consistency of metal castings, minimizing costly rework and material waste. Another crucial trend is the growing demand for lightweight and high-strength materials, particularly in the automotive and aerospace sectors. This has spurred advancements in aluminium metal casting techniques, including high-pressure die casting and vacuum die casting, which allow for the production of thinner-walled, more intricate parts with superior mechanical properties. The development of advanced aluminium alloy for casting is also a key area of focus, with researchers exploring new compositions that offer enhanced fatigue resistance, corrosion resistance, and thermal conductivity, essential for electric vehicle components and lightweight structural applications. These innovations are critical for achieving fuel efficiency and reducing emissions in transportation, aligning with global environmental objectives.

Sustainability is another driving force in the evolution of metal castings. Foundries are increasingly investing in greener practices, such as optimizing energy consumption, reducing waste, and recycling materials. The use of recycled scrap metal as a primary feedstock is becoming more prevalent, not only for its environmental benefits but also for its economic advantages. Technologies like induction melting furnaces, which offer higher energy efficiency compared to traditional cupola furnaces, are being widely adopted. Furthermore, advancements in mold materials, including more environmentally friendly binders for green sand metal casting, are reducing emissions and improving workplace safety. The focus on circular economy principles within the metal castings sector means that components at the end of their lifecycle can often be recycled back into new castings, minimizing their overall environmental footprint. Beyond materials and processes, there's a significant trend towards integrated manufacturing solutions. This involves seamless collaboration between design, simulation, casting, and post-processing stages. The rise of additive manufacturing (3D printing) for creating complex mold cores and patterns is also impacting the industry, particularly for prototyping and low-volume production of highly intricate metal castings. This allows for faster iteration cycles and the creation of geometries that would be impossible or prohibitively expensive with traditional tooling. The continuous innovation in materials, processes, and digital integration ensures that metal castings will remain at the forefront of industrial manufacturing, adapting to new challenges and delivering high-performance solutions for an increasingly demanding global market.

Comprehensive Process Flow of Metal Castings Manufacturing

The production of high-quality metal castings is a multi-stage process that demands precision, control, and a deep understanding of metallurgy. It typically begins with design and simulation, where engineers use Computer-Aided Design (CAD) software to create a 3D model of the desired part. This digital model is then subjected to Casting Process Simulation (CPS) software, which simulates mold filling, solidification, and cooling. This crucial step helps identify potential defects like shrinkage, porosity, or cold shuts before physical production, allowing for optimization of gating systems, risers, and chill placement. For instance, in aluminium metal casting, precise simulation of fluid dynamics ensures complete mold filling without premature solidification or air entrapment. Following successful simulation, the next stage is pattern and mold creation. The pattern is a replica of the desired casting, slightly oversized to account for metal shrinkage. For green sand metal casting, patterns are typically made from wood, metal, or plastic. For more intricate or high-volume production, permanent molds or aluminum casting die are machined from steel. The mold cavity is then formed around the pattern using sand, ceramic, or metal. The mold includes channels (gates) for molten metal entry, risers to compensate for shrinkage during solidification, and vents for gas escape. The material chosen for the mold depends on the casting method; for example, expendable molds are used for sand casting and investment casting, while permanent molds are used for die casting.

The core of the metal castings process is melting and pouring. Raw materials, including virgin metal ingots and recycled scrap, are melted in furnaces, typically induction furnaces, arc furnaces, or cupolas, to reach the precise pouring temperature. Alloying elements are added during this stage to achieve the desired material properties, such as strength, hardness, or corrosion resistance. For specialized applications requiring exceptional purity and performance, such as stainless steel investment casting, vacuum induction melting (VIM) may be employed to minimize gas entrapment and oxidation. Once the molten metal reaches the correct temperature and composition, it is carefully poured into the prepared mold cavity. The pouring speed and temperature are critical to prevent defects like misruns or turbulence. After pouring, the metal undergoes solidification and cooling. As the molten metal cools within the mold, it solidifies, taking the shape of the cavity. Controlled cooling is vital to achieve the desired microstructure and mechanical properties. Rapid or uneven cooling can lead to stress or cracking. Once solidified, the casting is removed from the mold in the shakeout/demolding stage. For sand molds, this involves breaking away the sand. For die castings, the part is ejected from the die. The next critical steps are fettling and cleaning, where excess material such as gates, risers, and flash (excess metal that squeezed out) are removed. This can involve cutting, grinding, or shot blasting. The casting is then cleaned to remove any remaining sand, scale, or debris.

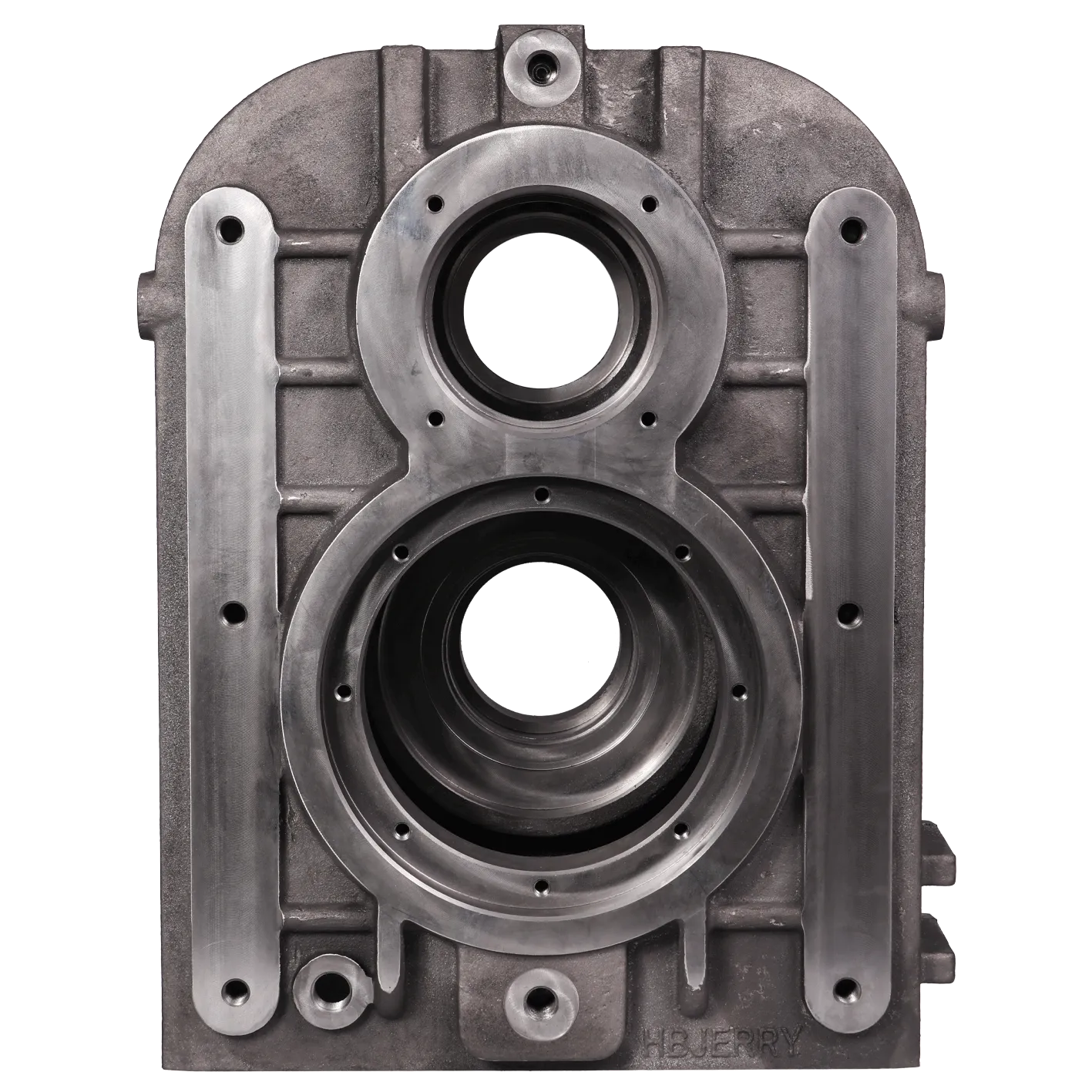

Subsequent to primary cleaning, many metal castings undergo heat treatment to enhance their mechanical properties. This can include annealing for stress relief, normalizing for grain refinement, quenching for hardening, or tempering for ductility improvement. For instance, many aluminium alloy for casting parts undergo T6 heat treatment to achieve optimal strength. The final stages involve machining and finishing if required, to achieve precise dimensional tolerances, intricate features, or superior surface finishes. CNC machining is often employed for high precision requirements. Finally, inspection and quality control are paramount. This involves a range of non-destructive testing (NDT) methods such as visual inspection, dimensional checks using CMMs (Coordinate Measuring Machines), ultrasonic testing for internal flaws, X-ray radiography for subsurface defects, and dye penetrant inspection for surface cracks. Mechanical property tests (tensile, hardness, impact) and chemical analysis ensure the casting meets all specifications, including ISO and ANSI standards. The entire process is meticulously monitored to ensure that each metal castings component meets the stringent quality requirements for its intended use across diverse industries like petrochemical, metallurgy, and water supply/drainage systems, where reliability and performance are non-negotiable. Our manufacturing process for the Casting Box, for example, adheres to these rigorous standards, ensuring exceptional durability and performance, often outlasting competitors due to superior material integrity and precise manufacturing controls, contributing to energy savings and enhanced corrosion resistance in harsh operational environments.

Visual representation of a typical metal castings production line, emphasizing quality control checkpoints.

Material Science and Alloying in Metal Castings

The selection of the appropriate material is a pivotal decision in the production of high-performance metal castings, directly influencing the final product's strength, durability, corrosion resistance, and overall suitability for its intended application. The vast array of metals and alloys available allows for tailored solutions to meet specific engineering challenges. For instance, cast iron, in its various forms like gray, ductile, and malleable iron, remains a workhorse in industries requiring high compressive strength, excellent machinability, and good vibration damping characteristics, commonly found in engine blocks, machine bases, and pipes. Steel castings offer superior tensile strength, toughness, and weldability compared to cast iron, making them ideal for heavy-duty applications such as railway components, turbine housings, and large industrial valves. Within steel, there are numerous grades, including carbon steel, alloy steel, and stainless steel investment casting, each offering distinct advantages. Stainless steel, in particular, provides exceptional corrosion resistance and elevated temperature strength, crucial for components in chemical processing, food handling, and marine environments. The choice between austenitic, ferritic, martensitic, or duplex stainless steel depends on the specific corrosive environment, temperature range, and mechanical property requirements. Our expertise extends to advising clients on the optimal material selection, considering factors like operating temperatures, chemical exposure, load conditions, and cost efficiency to ensure the longevity and performance of every metal castings component.

Non-ferrous alloys constitute another critical segment of the metal castings market, with aluminium metal casting leading the charge due to its excellent strength-to-weight ratio, high thermal and electrical conductivity, and corrosion resistance. The versatility of aluminium alloy for casting makes it indispensable in the automotive industry for engine components, chassis parts, and structural elements where lightweighting is paramount for fuel efficiency and emission reduction. Beyond automotive, aluminum castings are vital in aerospace, consumer electronics, and lighting industries. Copper alloys, including brass and bronze, are valued for their excellent electrical and thermal conductivity, corrosion resistance, and wear properties, finding applications in plumbing fixtures, electrical connectors, and marine hardware. Zinc alloys, often processed via aluminum casting die techniques or other die-casting methods, offer excellent castability, high dimensional accuracy, and good mechanical properties for smaller, intricate parts. Nickel-based alloys are reserved for extreme environments, offering unparalleled resistance to high temperatures, creep, and aggressive corrosive media, common in gas turbines and chemical reactors. The precise alloying of these base metals with elements like silicon, magnesium, copper, zinc, nickel, and chromium allows for fine-tuning the metallurgical structure and properties, such as grain size, phase distribution, and precipitation hardening response, which directly impacts the casting's final performance. Advanced foundries meticulously control melt chemistry to achieve consistent, high-quality metal castings that adhere to international material specifications like ASTM, SAE, and EN standards. Our metallurgical engineers leverage state-of-the-art spectrographic analysis and mechanical testing facilities to verify the chemical composition and mechanical properties of every batch of molten metal and finished casting, ensuring full traceability and compliance.

Technical Parameters and Performance Metrics of Metal Castings

Understanding the key technical parameters and performance metrics is crucial when specifying or evaluating metal castings. These metrics directly impact the suitability of a cast component for its intended application and are often critical for meeting design and safety requirements. One of the primary parameters is dimensional accuracy and tolerance, which refers to how closely the final casting matches the design dimensions. Different casting processes offer varying levels of precision; for example, stainless steel investment casting typically yields much tighter tolerances than green sand metal casting due to the nature of the mold material and process control. Typical tolerances can range from ±0.005 inches for investment castings to ±0.030 inches or more for larger sand castings. Another vital metric is surface finish, expressed in Root Mean Square (RMS) or Ra (roughness average) values. A smoother surface reduces friction, improves aesthetic appeal, and can enhance corrosion resistance. Investment castings often boast very smooth surfaces (e.g., Ra 63-125 µin), while sand castings are rougher (e.g., Ra 250-500 µin), often requiring secondary machining for critical surfaces. Mechanical properties are paramount and include tensile strength (UTS), yield strength, elongation (ductility), hardness (Brinell, Rockwell), and impact strength (Charpy V-notch). These properties indicate a material's ability to withstand various forces and loads without failure. For instance, a high-strength aluminium alloy for casting might exhibit UTS over 300 MPa, while certain high-strength steels can exceed 1000 MPa.

Beyond basic mechanical properties, engineers also consider fatigue strength, which is the material's ability to withstand repetitive loading cycles without failure, critical for components in rotating machinery or vibratory environments. Corrosion resistance is another key parameter, particularly for metal castings used in harsh chemical, marine, or atmospheric conditions. This is often quantified by salt spray tests or immersion tests, and highly resistant materials like certain grades of stainless steel or specific copper alloys are chosen. Thermal conductivity and electrical conductivity are important for applications involving heat dissipation (e.g., heat sinks, engine components) or electrical current flow (e.g., electrical connectors). Density (or specific gravity) is crucial for lightweighting applications, especially with aluminium metal casting. Microstructural integrity refers to the internal structure of the casting, including grain size, presence of inclusions, and porosity. These can significantly impact mechanical properties and are evaluated using non-destructive testing (NDT) methods like X-ray radiography or ultrasonic inspection, as well as metallography. Porosity, for example, even at seemingly low levels, can act as stress concentrators and reduce fatigue life. The lifespan of a metal castings component is directly tied to these parameters, and rigorous testing against standards like ASTM, ISO, and ANSI ensures that components meet expected performance criteria. Our quality control processes include comprehensive material analysis, mechanical property testing, and NDT, providing detailed reports that verify compliance with all specified technical parameters, ensuring that the finished metal castings are fit for even the most demanding applications in petrochemical, metallurgy, and water supply and drainage sectors.

Typical Technical Parameters for Common Metal Castings Materials

| Parameter | Ductile Iron (e.g., ASTM A536 65-45-12) | Aluminum Alloy (e.g., A356-T6, aluminium alloy for casting) | Stainless Steel (e.g., CF8M, stainless steel investment casting) |

|---|---|---|---|

| Tensile Strength (UTS) | 450 MPa (65 ksi) min | 290 MPa (42 ksi) min | 485 MPa (70 ksi) min |

| Yield Strength (YS) | 310 MPa (45 ksi) min | 220 MPa (32 ksi) min | 170 MPa (25 ksi) min |

| Elongation | 12% min | 5% min | 30% min |

| Hardness (Brinell HB) | 187-255 HB | 90-110 HB | 207 HB max |

| Density (g/cm³) | 7.1 | 2.68 | 7.85 |

| Typical Dimensional Tolerance | ±0.020 in/in (large parts) | ±0.005 in (first inch) | ±0.005 in (first inch) |

| Typical Surface Finish (Ra) | 250-500 µin | 125-250 µin | 63-125 µin |

| Corrosion Resistance | Moderate (improved with coatings) | Good (excellent with anodizing) | Excellent |

Note: These values are typical and can vary based on specific alloy composition, casting process, heat treatment, and post-processing. Always consult material datasheets and perform application-specific testing for critical components.

Application Scenarios Across Diverse Industries

Metal castings are omnipresent in virtually every industrial sector, providing durable and complex components essential for machinery, infrastructure, and consumer goods. In the automotive industry, aluminium metal casting is critical for lightweighting efforts, found in engine blocks, cylinder heads, transmission cases, and wheels. The high strength-to-weight ratio of aluminium alloy for casting directly contributes to improved fuel efficiency and reduced emissions, a crucial factor in meeting stringent environmental regulations. As the industry shifts towards electric vehicles (EVs), metal castings continue to play a vital role in battery enclosures, motor housings, and structural components that benefit from precise thermal management and crashworthiness. Beyond lightweight alloys, cast iron components are still prevalent in brake drums, exhaust manifolds, and various powertrain parts due to their excellent wear resistance and vibration damping properties. The aerospace sector demands components with exceptional strength, fatigue resistance, and temperature stability. Here, stainless steel investment casting and other high-performance alloys like nickel-based superalloys are indispensable for turbine blades, structural brackets, and engine components operating under extreme conditions. The ability to produce complex, near-net-shape parts with high dimensional accuracy minimizes costly machining and material waste, which is highly valued in aerospace manufacturing.

The petrochemical industry relies heavily on corrosion-resistant metal castings for valves, pumps, fittings, and heat exchanger components that handle aggressive chemicals, high pressures, and elevated temperatures. Stainless steel and specialized nickel alloys are frequently chosen to withstand highly corrosive media and prevent costly downtime due to material degradation. In the metallurgy and mining sectors, cast components are subjected to extreme abrasion, impact, and high loads. Here, high-manganese steels and wear-resistant cast irons are used for crushing equipment, grinding mill liners, and heavy machinery parts. The robustness and long lifespan of these metal castings are paramount for maintaining operational continuity and safety in challenging environments. The water supply and drainage industry utilizes metal castings for a vast array of components, including pipes, fittings, valve bodies, pump housings, and hydrants. Ductile iron castings are particularly popular due to their strength, ductility, corrosion resistance, and ease of installation. Our "Casting Box" product, for example, is specifically designed for these types of applications, offering unparalleled durability and reliability in critical infrastructure. In the power generation sector, from traditional fossil fuel plants to renewable energy installations (wind turbines, hydroelectric dams), large metal castings are vital for turbine casings, generator frames, and structural supports, requiring exceptional strength, thermal stability, and long-term reliability.

Even seemingly disparate industries like agriculture (tractor parts, implements), construction (heavy equipment, structural connectors), and marine (propellers, structural elements, engine components) extensively leverage metal castings. The diversity of applications underscores the fundamental role of casting as a manufacturing process capable of delivering components with optimized performance characteristics tailored to specific environmental and operational demands. For example, in shipbuilding, large metal castings for stern frames, rudders, and propulsion system components must withstand constant exposure to saltwater and immense mechanical stresses. Our extensive experience across these diverse sectors means we understand the unique challenges and requirements of each, enabling us to provide precisely engineered metal castings that contribute to enhanced performance, greater efficiency, and extended service life for your critical systems. The ability of modern metal castings to be customized for specific chemical resistances, temperature ranges, and mechanical loads makes them an indispensable solution where other manufacturing methods fall short in providing the required complexity or material properties at scale.

Advantages of Advanced Metal Castings Solutions

The strategic adoption of advanced metal castings solutions offers a multitude of technical and economic advantages over alternative manufacturing processes like fabrication, forging, or extensive machining. One of the foremost benefits is the ability to produce highly complex geometries with intricate internal passages and external features that would be difficult, if not impossible, to achieve economically through other methods. This design freedom allows engineers to consolidate multiple components into a single casting, reducing assembly costs, minimizing potential leak points, and improving overall structural integrity. For instance, a complex pump housing with integrated flow channels can be cast as a single unit, avoiding the welding and sealing required if fabricated from multiple plates. This inherent ability to create near-net-shape components also leads to significant material savings and reduced machining requirements, thereby lowering production costs and minimizing waste, which aligns with sustainable manufacturing practices. The efficiency gained from reduced material consumption and less post-processing directly translates into a more competitive product.

Another compelling advantage lies in the versatility of material selection. Metal castings can be produced from a vast array of ferrous and non-ferrous alloys, each offering specific properties tailored to the application's demands, such as exceptional strength, high corrosion resistance, superior wear resistance, or excellent thermal conductivity. This includes specialized alloys for extreme environments, like those used in stainless steel investment casting for corrosive media or high-temperature applications. The controlled solidification process in casting allows for the development of specific microstructures that enhance desired material properties, often leading to improved fatigue life and overall durability compared to welded structures that may suffer from heat-affected zone issues. Furthermore, metal castings generally exhibit isotropic properties (uniform properties in all directions) or controlled anisotropy, which is beneficial for components subjected to multi-directional stresses. This contrasts with forged parts, which often have directional grain flow, and fabricated parts with weld lines that can be points of weakness. For large, heavy-duty components, casting is often the most cost-effective method for high-volume production, as the tooling cost, once amortized, is significantly lower per part than machining from solid billets or assembling complex fabrications. This economic efficiency, combined with the ability to produce large, robust components, makes metal castings the preferred choice for industrial machinery, infrastructure, and energy sector applications.

Beyond these technical and economic benefits, advanced metal castings solutions offer enhanced performance under extreme conditions. Components subjected to high temperatures, aggressive chemicals, or abrasive environments can be specifically engineered with alloys and heat treatments that provide extended service life. For example, a specialized aluminium alloy for casting might be designed for superior heat dissipation in an electronic enclosure, while a custom cast iron may offer exceptional vibration damping for a machine base. The longevity and reliability of our metal castings contribute to reduced maintenance, minimized downtime, and ultimately, a lower total cost of ownership for our clients. In industries such as petrochemical, where component failure can have catastrophic consequences, the proven reliability and consistent quality of cast components are invaluable. Our expertise in designing and manufacturing metal castings means we can optimize designs for weight reduction, improved strength, and enhanced functionality, often leading to energy savings for the end-user by providing more efficient geometries or reducing system weight. The integrated approach we take, from initial design consultation to final inspection, ensures that our metal castings not only meet but often exceed the performance expectations for their critical applications, offering distinct advantages in terms of durability, cost-effectiveness, and operational efficiency.

Manufacturer Comparison and Selection Criteria for Metal Castings

Selecting the right manufacturer for metal castings is a critical decision that significantly impacts product quality, cost-efficiency, and project timelines. It involves a thorough evaluation of several key criteria beyond just the quoted price. Firstly, a manufacturer's technological capability and equipment are paramount. Does the foundry possess state-of-the-art melting furnaces, advanced molding lines (e.g., automated green sand metal casting lines, sophisticated aluminum casting die equipment for die casting, or precision investment casting lines for stainless steel investment casting)? Are they utilizing modern simulation software (e.g., MAGMASOFT®, ProCAST) for mold flow and solidification analysis? The presence of advanced equipment and software indicates a commitment to precision, efficiency, and defect reduction. Secondly, material expertise and metallurgical control are crucial. A reputable foundry should have in-house metallurgical engineers capable of advising on optimal alloy selection (including specialized aluminium alloy for casting), controlling melt chemistry, and performing thorough material analysis. This ensures that the final metal castings possess the exact mechanical properties and chemical resistance required for your application. Ask about their process for material verification and their range of available alloys.

Thirdly, quality assurance and certifications are non-negotiable. Look for manufacturers with internationally recognized certifications such as ISO 9001, which signifies a robust quality management system. Additional industry-specific certifications (e.g., IATF 16949 for automotive, AS9100 for aerospace, PED for pressure equipment) demonstrate specialized competence. Inquire about their non-destructive testing (NDT) capabilities (e.g., X-ray, ultrasonic, magnetic particle inspection, dye penetrant inspection) and their quality control procedures throughout the manufacturing process. A comprehensive QC system ensures consistent quality and compliance with critical standards like ANSI. Fourthly, evaluate their experience and track record. How many years has the manufacturer been in business? Can they provide references or case studies from clients in similar industries or with comparable product requirements? A long history of successful projects, particularly for complex metal castings, indicates reliability and problem-solving capability. For instance, a foundry with extensive experience in precision components for the petrochemical sector will understand the nuances of high-pressure and corrosive environment applications. Furthermore, assess their design and engineering support. Do they offer collaborative design services, including DFM (Design for Manufacturability) advice, to optimize your component for casting, reducing costs, and improving performance? The ability to provide valuable input during the design phase can significantly streamline your project.

Lastly, consider their production capacity and flexibility and their supply chain management. Can they handle your required volumes, from prototyping to mass production? What are their typical lead times, and how do they manage unexpected changes or urgent demands? A robust supply chain, from raw material sourcing to logistics, is vital for on-time delivery. Evaluate their responsiveness to inquiries, clarity of communication, and commitment to customer support, which are indicative of a reliable partnership. Our extensive experience over [Insert number of years, e.g., 20+] years, coupled with our ISO 9001 certified processes and state-of-the-art facility, positions us as a leading provider of high-quality metal castings. We pride ourselves on our technical expertise, collaborative approach, and unwavering commitment to delivering exceptional components. We invite prospective clients to review our certifications, visit our facility, and speak with our existing customers to understand why we are a trusted partner for critical metal castings solutions across diverse industries, ensuring components that offer extended lifespan and contribute to energy efficiency. Our dedicated teams and advanced equipment for all casting methods, including those specific to aluminium metal casting and large industrial parts, are optimized to meet the most stringent specifications for applications in demanding sectors like petrochemical, metallurgy, and water treatment.

Customized Solutions and Design Optimization for Metal Castings

In today's competitive industrial landscape, off-the-shelf components often fall short of meeting the unique performance and integration requirements of specialized applications. This is where customized metal castings solutions become invaluable. Tailoring a cast component to specific design parameters ensures optimal functionality, improves system efficiency, and can significantly reduce overall project costs by eliminating the need for complex assemblies or secondary machining. The process of developing a customized casting begins with a deep collaboration between the client's engineering team and our design and metallurgy experts. This initial consultation focuses on understanding the component's operational environment, load conditions, desired lifespan, critical dimensions, and any specific material requirements, such as resistance to corrosion or high temperatures. For instance, a bespoke aluminium alloy for casting might be developed to meet a unique strength-to-weight ratio requirement for a new aerospace component, or a specialized stainless steel investment casting design might integrate complex internal geometries for a fluid control valve in a nuclear power plant. Our engineers leverage advanced CAD/CAM tools to translate conceptual designs into precise 3D models, ensuring every detail is captured.

A key aspect of customized metal castings is design optimization for manufacturability (DFM). Even a technically sound design can be problematic if it's not optimized for the casting process. Our DFM specialists review designs for features like appropriate wall thicknesses, radii, draft angles, and parting line considerations, which are critical for successful mold filling, solidification, and defect prevention. For aluminum casting die processes, optimizing gate design and runner systems is essential for minimizing porosity and maximizing die life. For green sand metal casting, considerations like core placement and shakeout ease are paramount. By identifying potential manufacturing challenges early in the design phase, we can make modifications that reduce tooling costs, improve yield rates, and shorten lead times. This proactive approach not only prevents costly rework but also ensures that the final metal castings meet performance expectations from the first production run. Advanced simulation software is integral to this optimization process, allowing us to predict and mitigate issues such as shrinkage, warpage, or cold shuts before any metal is poured. This virtual prototyping significantly accelerates the design cycle and enhances the reliability of the custom part.

Beyond geometric optimization, customization extends to material selection and metallurgical enhancement. We work closely with clients to select the ideal alloy or even develop new alloy compositions if standard options don't suffice. This could involve modifying an existing aluminium alloy for casting to enhance its ductility or formulating a new cast iron with improved wear characteristics for mining equipment. Heat treatment recipes are also custom-tailored to achieve specific mechanical properties, such as precise hardness levels, increased tensile strength, or improved fatigue resistance for critical metal castings. Furthermore, we offer a range of post-casting operations including precision CNC machining, surface finishing (e.g., polishing, coating, painting), and specialized joining methods to deliver a complete, ready-to-integrate component. For example, a custom-designed `Casting Box` might require precise CNC-machined interfaces and a specialized anti-corrosion coating for optimal performance in harsh wastewater treatment plants. Our comprehensive approach to customized metal castings ensures that every component is engineered to deliver peak performance, offering a competitive advantage by perfectly integrating into your systems, enhancing efficiency, and providing exceptional longevity in applications ranging from critical petrochemical installations to large-scale water management projects.

Showcasing the intricacy and precision achievable with customized metal castings for specific industrial needs.

Case Studies and Real-world Applications

To illustrate the tangible benefits of high-quality metal castings, let's delve into several real-world application examples where our solutions have delivered significant value. Case Study 1: High-Performance Pump Housing for Petrochemical Industry A major client in the petrochemical sector faced recurring issues with pump housings experiencing premature corrosion and wear in highly aggressive chemical environments. Their existing fabricated housings required frequent replacement, leading to costly downtime and maintenance. Our solution involved designing and manufacturing a specialized pump housing using stainless steel investment casting with a specific duplex stainless steel alloy (e.g., CD3MN). This alloy was selected for its superior resistance to chloride-induced stress corrosion cracking and pitting. Through advanced casting simulation, we optimized the internal flow channels and wall thickness distribution, ensuring uniform solidification and minimizing porosity, which are critical for pressure containment. The near-net-shape capability of investment casting also significantly reduced the need for post-machining, saving time and cost. The resulting metal castings provided a 3x increase in lifespan compared to the fabricated components, reducing maintenance costs by 40% annually and significantly enhancing operational reliability. This particular solution also contributed to energy efficiency by reducing frictional losses within the optimized fluid pathways.

Case Study 2: Lightweight Automotive Structural Component via Aluminium Metal Casting An automotive OEM sought to reduce vehicle weight without compromising structural integrity or crashworthiness, aiming for improved fuel economy and reduced emissions. They approached us to replace a multi-piece welded steel subframe component with a single, lightweight cast aluminum part. We proposed an aluminium metal casting solution using a high-strength aluminium alloy for casting, specifically A356-T6, known for its excellent castability and mechanical properties after heat treatment. Leveraging our expertise in aluminum casting die design, we engineered a complex die that allowed for intricate ribbing and thin-wall sections (down to 3mm), optimizing material distribution for maximum strength-to-weight ratio. Our simulation tools were critical in ensuring precise mold filling and predicting solidification shrinkage, guaranteeing dimensional accuracy and preventing hot tearing. The final cast component weighed 35% less than the original steel assembly, while passing all stringent crash tests and fatigue life requirements. This directly resulted in a measurable improvement in vehicle performance and a substantial contribution to the OEM's lightweighting objectives, demonstrating the clear advantage of advanced metal castings in automotive innovation.

Case Study 3: Large-Scale Industrial Valve Body for Water Treatment For a municipal water treatment plant expansion, there was a critical need for large, durable valve bodies capable of withstanding high pressures and corrosive treated water for decades. Traditional solutions often involved components that were either too heavy or prone to premature failure. Our team recommended large-scale green sand metal casting using ductile iron (ASTM A536 Grade 65-45-12) for its excellent strength, ductility, and machinability. The challenge was casting such large components (up to 2,000 kg) with consistent quality and minimal internal defects. We developed specialized gating and riser systems to ensure progressive solidification and eliminate shrinkage porosity, validating the design through comprehensive casting simulations. After casting, each valve body underwent rigorous non-destructive testing, including ultrasonic inspection, to confirm internal soundness. The resulting metal castings provided superior long-term performance compared to previous solutions, offering exceptional corrosion resistance and mechanical integrity for a projected lifespan of over 50 years. This project underscored our capability to deliver large, complex, and reliable metal castings for critical infrastructure, showcasing how our products like the `Casting box` are designed for longevity and resilience in demanding public utility applications. These case studies highlight our commitment to engineering excellence and delivering tailored metal castings solutions that address specific client challenges, resulting in enhanced performance, reduced costs, and improved reliability across a spectrum of industrial applications.

Quality Assurance, Certifications, and Compliance

At YD Castings, our commitment to delivering superior metal castings is underpinned by a rigorous and comprehensive quality assurance system. This system is not merely a series of checks but an integrated philosophy that permeates every stage of our manufacturing process, from raw material inspection to final product delivery. We understand that the reliability and safety of your operations depend on the unwavering quality of our components. Our foundry operates under the strict guidelines of ISO 9001:2015 certification, which is a testament to our robust quality management system. This international standard ensures that we consistently meet customer and regulatory requirements and are dedicated to continuous improvement. Beyond ISO 9001, we adhere to a multitude of industry-specific standards and specifications, including ASTM (American Society for Testing and Materials), ANSI (American National Standards Institute), SAE (Society of Automotive Engineers), and various EN (European Norm) standards, depending on the application and client requirements. For example, stainless steel investment casting destined for pressure vessel applications might also comply with PED (Pressure Equipment Directive) or ASME Boiler and Pressure Vessel Code requirements. Our compliance extends to material traceability, ensuring that the chemical composition and mechanical properties of every batch of metal can be tracked back to its origin.

Our quality control procedures for metal castings involve a multi-layered approach, beginning with the meticulous inspection of incoming raw materials. Spectrographic analysis is performed on all incoming ingots and scrap to verify their chemical composition before melting, preventing contamination and ensuring the correct alloy formulation. During the melting and pouring stages, regular ladle analysis ensures the molten metal chemistry remains within specified tolerances for alloys like aluminium alloy for casting or specific grades of ductile iron. After solidification and shakeout, each casting undergoes visual inspection for surface defects. This is followed by dimensional inspection using precision measuring tools, including Coordinate Measuring Machines (CMMs) for complex geometries, ensuring that all tolerances are met. For critical metal castings where internal integrity is paramount, we employ a full suite of Non-Destructive Testing (NDT) methods. This includes X-ray radiography (RT) to detect internal voids, shrinkage, or inclusions; ultrasonic testing (UT) for subsurface cracks or porosity; magnetic particle inspection (MPI) for surface and near-surface cracks in ferrous castings; and liquid penetrant inspection (LPI) for surface-breaking defects in non-porous materials. These tests provide absolute assurance regarding the structural soundness of the cast components.

Furthermore, mechanical property testing is routinely conducted on test bars cast from the same heat as the production parts. This includes tensile testing to determine ultimate tensile strength, yield strength, and elongation; hardness testing (Brinell, Rockwell, or Vickers) to assess resistance to indentation; and Charpy impact testing to evaluate toughness and resistance to brittle fracture, especially important for metal castings subjected to shock loads or low temperatures. For applications like those utilizing aluminum casting die processes, specific fatigue testing may also be performed to predict the component's lifespan under cyclic loading. Our quality management team works diligently to maintain comprehensive documentation for every production batch, including material certificates, inspection reports, and NDT results. This commitment to transparency and rigorous testing ensures that every metal castings component leaving our facility is of the highest quality, providing unparalleled reliability and an extended service life in demanding industrial applications, from petrochemical and metallurgy to water supply and drainage systems, where performance under stress and corrosive conditions is a continuous challenge. Our dedication to quality is a direct reflection of our belief that our `Casting box` and all our products are integral to the safety and success of our clients' operations.

Frequently Asked Questions (FAQ) About Metal Castings

Q1: What are the primary advantages of metal castings over other manufacturing methods like fabrication or machining?

Metal castings offer several distinct advantages. They allow for the creation of highly complex and intricate geometries, including internal passages and hollow sections, often in a single piece, reducing assembly time and costs. This near-net-shape capability also minimizes material waste and machining requirements, leading to cost savings. Furthermore, casting provides excellent material versatility, allowing for the use of a wide range of alloys, from high-strength steels and corrosion-resistant stainless steel investment casting to lightweight aluminium metal casting, each tailored for specific mechanical and environmental conditions. Castings also tend to have isotropic properties, meaning uniform strength in all directions, which is beneficial for components under multi-directional stress. They are also generally more cost-effective for high-volume production of large or complex parts.

Q2: How do you ensure the quality and dimensional accuracy of your metal castings?

Our commitment to quality is upheld through a multi-faceted approach. We start with rigorous raw material inspection and chemical analysis to ensure proper alloy composition, including for specific grades of aluminium alloy for casting. During the manufacturing process, we utilize advanced casting simulation software to optimize mold designs and predict potential defects. Our facilities are ISO 9001:2015 certified, signifying a robust quality management system. We employ a comprehensive range of quality control measures, including visual inspection, precise dimensional checks using CMMs, and extensive Non-Destructive Testing (NDT) methods like X-ray, ultrasonic, magnetic particle, and dye penetrant inspection to detect any internal or surface flaws. Mechanical property tests (tensile, hardness, impact) are routinely performed on every batch to confirm material performance. This holistic approach ensures every metal castings component meets stringent industry standards like ISO and ANSI and client specifications.

Q3: What types of metal castings processes do you specialize in, and for what applications?

We specialize in a broad range of metal castings processes to meet diverse industrial needs. Our capabilities include traditional green sand metal casting for large, heavy-duty components and cost-effective production, often used in metallurgy and heavy machinery. We excel in high-pressure die casting and gravity casting for precision aluminium metal casting, ideal for lightweight automotive and electronic components, often utilizing specialized aluminum casting die technology. For intricate parts requiring superior surface finish and tight tolerances, we offer stainless steel investment casting, favored in aerospace, medical, and high-performance industrial applications. We also produce ductile iron and various steel castings for applications requiring high strength, wear resistance, or specific corrosion properties, common in petrochemical, power generation, and water supply and drainage systems. Our expertise allows us to recommend the most suitable casting method based on your component's design, material requirements, volume, and budget.

Q4: Can you provide custom metal castings solutions based on our specific design requirements?

Absolutely. Customization is a core strength of our service offering for metal castings. Our experienced engineering team works collaboratively with clients from the initial concept phase, providing Design for Manufacturability (DFM) guidance to optimize your component for the casting process, ensuring maximum efficiency and cost-effectiveness. We can assist with material selection, recommending the best aluminium alloy for casting or other metals based on your performance criteria, or even developing custom alloys. We utilize advanced CAD/CAM and simulation tools to develop precise 3D models and predict casting behavior, ensuring that your custom metal castings meet exact specifications for dimensions, mechanical properties, and performance in critical applications. Whether it's a unique geometry, specific strength requirement, or specialized surface finish, we are equipped to deliver tailored solutions.

Q5: What is your typical delivery timeframe for metal castings orders?

Delivery timeframes for metal castings can vary significantly depending on several factors, including the complexity of the part, the chosen casting process (e.g., permanent mold vs. sand casting), the material, the volume of the order, and current production schedules. For new custom orders requiring tooling development (like an aluminum casting die), the initial lead time will be longer than for repeat orders. Generally, prototype or low-volume custom orders might take 8-12 weeks from design approval to initial sample delivery. For established, high-volume production, lead times can range from 4-8 weeks. We provide detailed lead time estimates at the quoting stage and maintain transparent communication throughout the production process to keep you informed of your order status. We prioritize efficient scheduling and leverage advanced production planning systems to meet agreed-upon deadlines consistently.

Delivery, Warranty, and Customer Support

At YD Castings, we understand that reliable delivery, robust warranty, and responsive customer support are as crucial as the quality of the metal castings themselves. Our commitment extends beyond the manufacturing floor to ensure a seamless and satisfactory experience for our clients. Delivery Logistics and Efficiency: We prioritize efficient and timely delivery of all metal castings orders. Our logistics team works closely with clients to establish realistic delivery schedules, considering production lead times, shipping methods, and specific project milestones. We manage global shipping and local delivery, ensuring products reach your facility safely and on schedule. For international shipments, we handle all necessary documentation and customs procedures to minimize delays. We also offer various packaging options, from bulk to individually protected components, designed to safeguard the integrity of your metal castings during transit, regardless of their size or complexity, be it precision stainless steel investment casting or large industrial components from green sand metal casting. Our advanced inventory management and production planning systems enable us to provide accurate lead times and adapt quickly to changes in demand, ensuring consistency for high-volume orders, for example, of aluminium metal casting automotive components.

Comprehensive Quality Warranty: We stand behind the quality and performance of every metal castings component we produce. Our products are manufactured to stringent international standards (e.g., ISO, ANSI, ASTM) and client-specific specifications. We offer a comprehensive warranty that covers manufacturing defects and material non-conformance for a specified period from the date of delivery. This warranty assures our clients that components like our `Casting box` are free from defects in material and workmanship and will perform as specified under normal operating conditions. In the unlikely event of a quality issue, our dedicated quality assurance team will promptly investigate and work towards a satisfactory resolution, which may include repair, replacement, or credit, depending on the nature of the issue. Our focus is always on ensuring your operational continuity and minimizing any potential disruption caused by component failure. This commitment to quality and accountability is a cornerstone of our long-term partnerships.

Dedicated Customer Support and Technical Assistance: Our relationship with clients doesn't end after delivery. We provide ongoing customer support and technical assistance to ensure the long-term success of your projects. Our team of experienced engineers and customer service professionals is readily available to answer your questions, provide technical guidance, and assist with any challenges that may arise during installation or operation of our metal castings. Whether you need clarification on material properties, assistance with design integration, or troubleshooting advice for components like those produced via aluminum casting die or using a specific aluminium alloy for casting, our experts are here to help. We offer multiple channels for support, including phone, email, and online inquiry forms, ensuring that you can reach us conveniently. We also welcome feedback, as it enables us to continuously improve our products and services. Our proactive approach to customer care ensures that you receive prompt, knowledgeable, and effective support, reinforcing our role as a trusted partner in providing high-performance metal castings for your most critical applications across petrochemical, metallurgy, and water supply/drainage industries.

Conclusion and Future Outlook for Metal Castings

The journey through the intricate world of metal castings reveals an industry steeped in tradition yet constantly innovating. From the foundational principles of pouring molten metal into molds to the cutting-edge applications of advanced alloys and digital simulation, metal castings remain an indispensable backbone of global manufacturing. We have explored the meticulous process flow, the diverse material science behind alloys like aluminium alloy for casting and stainless steel investment casting, the critical technical parameters ensuring performance, and the pervasive application across sectors ranging from petrochemical to water infrastructure. The inherent advantages of casting – the ability to create complex, near-net-shape geometries, utilize a vast array of materials, and achieve superior mechanical properties – underscore its enduring relevance and strategic importance for industries seeking durable, cost-effective, and high-performance components. Our discussion also highlighted the critical role of choosing the right manufacturing partner, emphasizing the importance of technological capability, material expertise, stringent quality assurance, and dedicated customer support, all of which are hallmarks of YD Castings' commitment to excellence.

Looking ahead, the future of metal castings is poised for continued evolution, driven by advancements in materials science, digitalization, and sustainable practices. The push for lightweighting in transportation will accelerate innovations in aluminium metal casting and the development of new high-strength, low-density alloys. The adoption of Industry 4.0 technologies, including AI-driven process optimization, advanced robotics for casting and post-processing, and the widespread use of digital twin technology, will further enhance efficiency, reduce defects, and shorten development cycles for metal castings. Furthermore, sustainability will increasingly dictate innovation, with greater emphasis on energy-efficient melting, reduced waste generation, increased use of recycled materials, and the development of greener mold binders, particularly for processes like green sand metal casting. As global demand for complex, high-performance components continues to grow across critical sectors like renewable energy, advanced robotics, and intelligent infrastructure, the role of metal castings will only become more pronounced. Foundries that embrace these technological shifts and maintain an unwavering focus on quality, precision, and customer collaboration will undoubtedly lead the industry forward.

At YD Castings, we are not merely manufacturers; we are innovators and strategic partners dedicated to pushing the boundaries of what's possible with metal castings. Our continuous investment in research and development, state-of-the-art facilities, and the expertise of our metallurgical engineers ensures that we remain at the forefront of the industry. We are committed to providing customized solutions that address your unique engineering challenges, enhance the performance of your products, and contribute to your long-term success. From the precise control required for intricate aluminum casting die components to the robust demands of large-scale industrial valve bodies like our `Casting box` product, we deliver reliable, high-quality metal castings designed for longevity and optimal performance. As your trusted partner, we are ready to collaborate on your next project, transforming your design concepts into robust, high-performance cast solutions that meet the demands of tomorrow's industrial landscape.

Industry Citations & Further Reading

-

Journal Article: "Advances in Aluminum Casting Alloys for Automotive Applications."

Author: J. Campbell, Publisher: International Journal of Cast Metals Research, Volume 30, Issue 1, 2017, pages 1-13.

-

Industry Report: "Global Metal Casting Market Size, Share & Trends Analysis Report."

Source: Grand View Research, Published: January 2024.

-

Academic Publication: "Investment Casting: A Review of Process, Materials and Applications."

Author: V. Kumar, K. Singh, Journal: Materials Today: Proceedings, Volume 4, Issue 2, 2017, pages 3156-3165.

-

Industry Association Resource: "Foundry Industry Best Practices for Sustainability."

Source: American Foundry Society (AFS) - Environmental, Health & Safety (EHS) Division.

-

Technical Book Chapter: "Principles of Metal Casting."

Author: R.W. Heine, C.R. Loper, P.C. Rosenthal, Publisher: McGraw-Hill, (various editions, foundational text).

(Note: Direct online link to full book content not typically available, but widely cited in academic and industry circles.)

-

Superior Aluminum Castings in Automotive Engine PartsNewsAug.22,2025

-

Common Materials Used in Fan Housing ManufacturingNewsAug.22,2025

-

Symptoms of a Stuck Automobile Water Pump ImpellerNewsAug.22,2025

-

The Importance of Valve Castings in Water TreatmentNewsAug.22,2025

-

Welding Techniques for End Cap Stainless Steel FittingsNewsAug.22,2025

-

How to Install a Water Pump Connector ProperlyNewsAug.22,2025