Mobile:+86-311-808-126-83

Email:info@ydcastings.com

French

how to bronze cast

How to Bronze Cast A Step-by-Step Guide

Bronze casting is an ancient art that combines creativity and craftsmanship. This process transforms raw materials into exquisite sculptures, statues, and decorative items. Whether you're an aspiring artist or a seasoned sculptor, understanding the basics of bronze casting can open up new avenues for your artistic expression. Here’s a step-by-step guide on how to bronze cast, from initial preparation to the final touches.

Step 1 Create Your Model

The first step in bronze casting is to create a model of the object you wish to cast. This model can be made from various materials such as clay, wax, or even a solid object if you are working with the lost-wax method. If using clay, ensure it is pliable and can hold intricate details. For wax, shape it precisely as once it's coated, it will be melted away in the process.

Step 2 Create a Mold

Once your model is complete, the next step is to create a mold. This can be done using materials like silicone, plaster, or ceramic shell, depending on the detail and quality you desire. If you are using the lost-wax method, you will coat your wax model with a layer of investment material. The coating should be even and withstand the molten bronze’s heat.

Step 3 Wax Removal

If you chose the lost-wax method, the next phase involves heating the mold to a temperature where the wax can melt and drain away. This process typically requires a kiln. The heating also solidifies the investment material, forming a cavity that will ultimately hold the molten bronze.

Step 4 Preparing Bronze

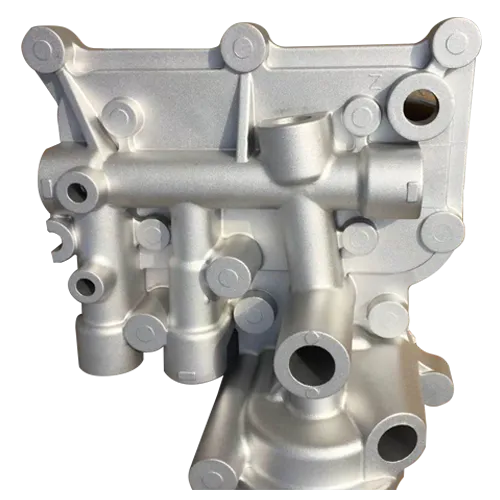

how to bronze cast

While the mold cools down, it’s time to prepare the bronze. Bronze is usually an alloy made from copper and tin, but depending on the desired finish or strength, other metals can be included. Melt the bronze in a furnace or crucible until it becomes liquide. Ensure to follow safety protocols, as handling molten metal can be hazardous.

Step 5 Pouring the Bronze

After the bronze has completely melted and reached the proper temperature, carefully pour it into the prepared mold. This step requires precision; any sudden movements can lead to spillage or defects. Allow the molten bronze to fill the mold completely and wait for it to cool and solidify, which might take several hours depending on the thickness of your casting.

Step 6 Breaking the Mold

Once the bronze has cooled completely, it’s time to break away the mold. This can involve chiseling the investment away or, in the case of silicone molds, carefully peeling them off. Be gentle to avoid damaging your newly cast piece.

Step 7 Finishing Touches

After removing the mold, you’ll likely have some rough edges or imperfections to address. Use tools like files, grinders, or sandpaper to smooth these surfaces. You may also want to add patina or other finishes to enhance the appearance of your sculpture. This stage is where you can truly personalize your work, establishing its character and style.

Conclusion

Bronze casting is not just about the technical process but also about infusing your artistic vision into every piece. The journey from a simple model to a finished bronze artwork can be immensely gratifying. Whether for personal projects or commercial purposes, mastering bronze casting can elevate your artistry to new heights, preserving your creations for generations. Dive in, experiment, and unleash the boundless potential of bronze!