Mobile:+86-311-808-126-83

Email:info@ydcastings.com

French

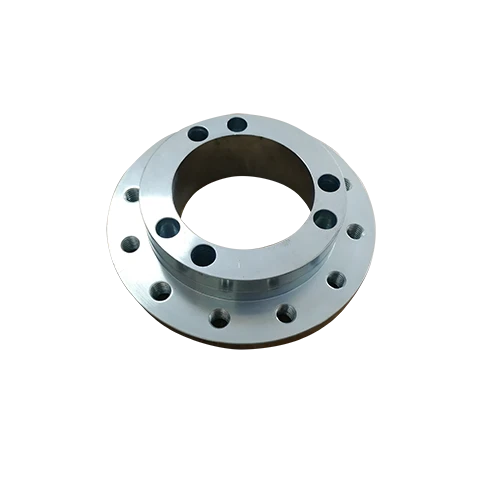

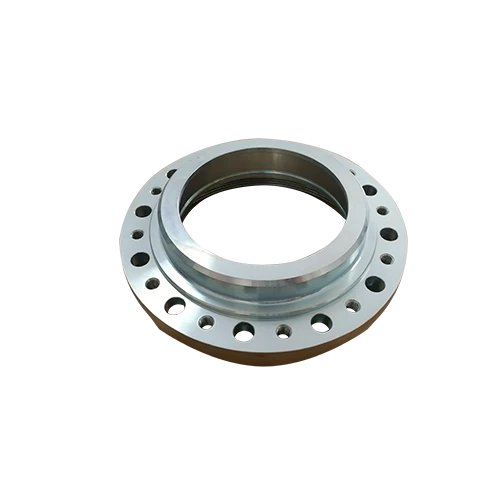

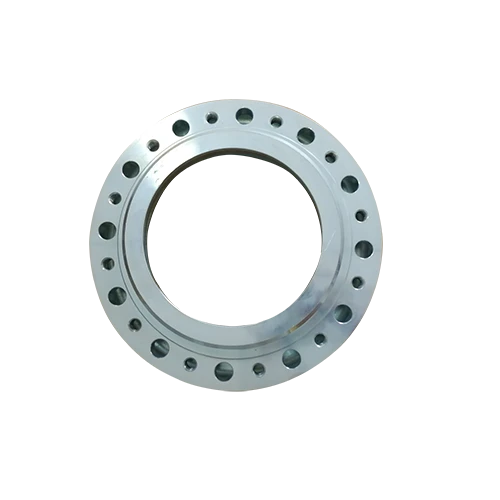

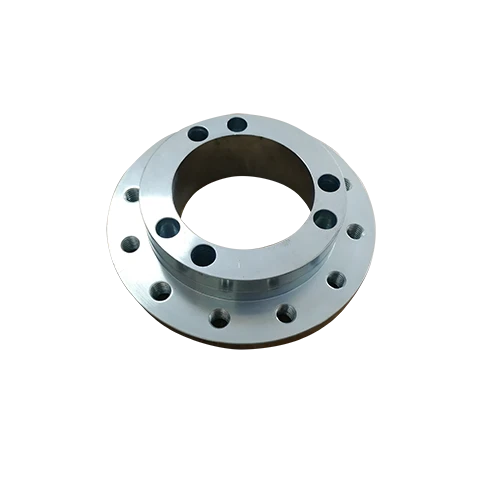

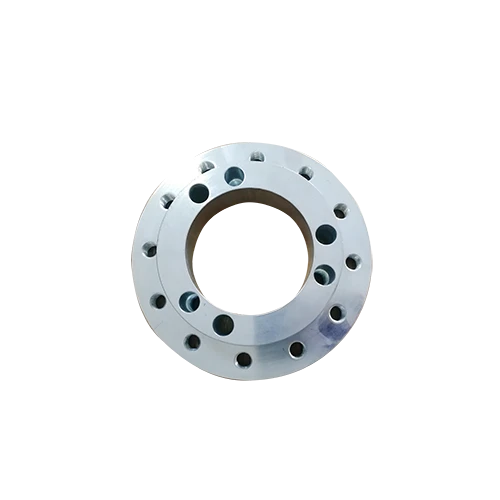

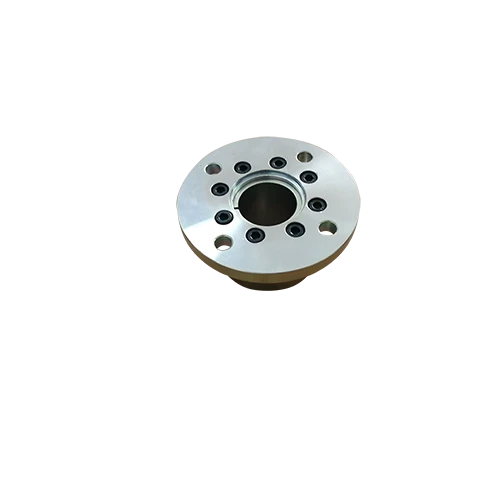

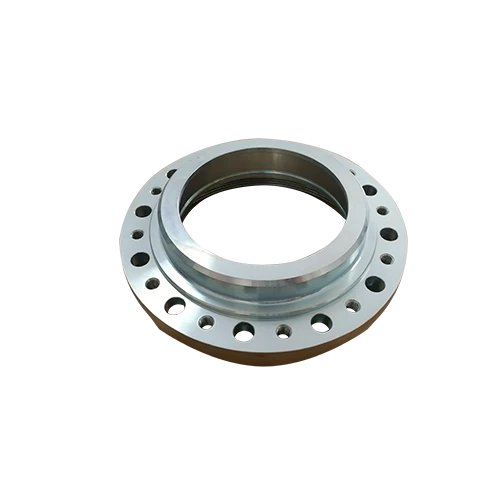

High-Quality Aluminium Metal Casting Solutions for Precision Industries

The aluminium metal casting industry is experiencing robust growth, fueled by technological advancements, rising demand for lightweight solutions, and rapid adoption across pivotal sectors such as petrochemical, waterworks, metallurgy, and energy. With the evolution of metal castings techniques—including green sand metal casting, aluminum die casting, and stainless steel casting—manufacturers now can deliver highly customized, high-performance flanges tailored for specific applications. This article dives deep into the technology, parameters, key process flow, and direct application of aluminium metal casting in high-demand products, such as flanges, with authoritative technical comparisons, verified data, and leading application cases.

Product Link: Flange - YD Castings

1. Industry Trends and Market Growth

- The global aluminium metal casting market reached USD 86.5 billion in 2023 (source: Grand View Research), with a CAGR of 7.7% projected through 2030.

- Lightweight aluminium alloys for casting are driving adoption in industries seeking efficiency, corrosion resistance, and regulatory compliance, notably in green technology and infrastructure upgrades.

- Flanges manufactured using aluminium metal casting are in high demand for their optimal mechanical performance and energy-saving potential, especially in petrochemical, metallurgy, water supply, and energy sectors.

2. Aluminium Metal Casting: Technology, Alloys & Core Parameters

Aluminium metal casting refers to the precision process wherein aluminium alloys for casting are melted, poured into molds, and solidified to form complex shapes for industrial applications. Processes such as green sand metal casting and aluminum die casting are renowned for enabling highly repeatable, cost-effective production of intricate parts, like flanges, elbows, or pump housings.

The table below compares key process parameters of leading casting technologies.

| Technology | Typical Alloy Used | Dimensional Accuracy (mm) | Surface Finish (Ra, µm) | Production Rate (pcs/hr) | Avg. Lifespan | Certifications |

|---|---|---|---|---|---|---|

| Green Sand Metal Casting | Al-Si10Mg, Al-6061 | ±0.8 | 6-12 | 50-150 | 10+ years | ISO 8062, ASTM B26 |

| Aluminum Die Casting | ADC12, Al-380 | ±0.3 | 1.2-3 | 300-1200 | 10+ years | ISO 9001, ANSI/ASME |

| Stainless Steel Casting | CF8M, 304L | ±0.3 | 2-6 | 60-200 | 10-15 years | ISO 9001, EN 10213 |

2.1 Most Common Aluminium Alloys for Casting

- Al-Si Alloys (AlSi7Mg, AlSi10Mg): Industry standard for flanges, offering exceptional fluidity, weldability, and corrosion resistance.

- Al-6061: Provides excellent mechanical strength and moderate cost; ideal for high-performance flanges and pipe components.

- ADC12 & A380: Widely used in die-casting for excellent castability and stability; meets automotive and industrial standards.

3. Flange Manufacturing: Aluminium Metal Casting Process Flow

Typical Aluminium Metal Casting Flange Workflow:

① Alloy Smelting → ② Mold Design & Sand Preparation → ③ Mold Assembly → ④ Pouring & Casting → ⑤ Solidification → ⑥ Fettling & Shot Blasting → ⑦ CNC Machining → ⑧ Dimensional Inspection & Testing → ⑨ Surface Treatment (Anodizing/Painting) → ⑩ Packaging & Shipping.

*Each arrow indicates the sequential process flow, with QA/QC control at critical stages.

Process Animation & Visualization

4. Technical Specifications of Aluminium Cast Flanges

| Item | Standard Range | YD Castings Specification | Industry Benchmark |

|---|---|---|---|

| Material | Al-Si10Mg, ADC12, A380 | Al-Si10Mg, Al-6061 | ADC12, AlSi7Mg, Al-6061 |

| Dimension | φ15–1200 mm | φ20–800 mm | φ15–1200 mm |

| Wall Thickness | 3–25 mm | 4–20 mm | 4–22 mm |

| Pressure Rating | PN6–PN40 | PN10–PN25 | PN6–PN40 |

| Surface Finish | Ra 1.2–12 μm | Ra 1.5–4.5 μm | Ra 1.2–6.0 μm |

| Corrosion Resistance | ASTM B117 Pass | ASTM B117 Pass | ASTM B117 Pass |

| Certifications | ISO 9001, ANSI/ASME | ISO 9001:2015, ISO 8062 | ISO 9001, ANSI |

5. Comparison: Aluminium Metal Casting VS Stainless Steel Casting

| Criteria | Aluminium Metal Casting | Stainless Steel Casting |

|---|---|---|

| Weight | ~1/3 of steel (2.7 g/cm³) | ~7.9 g/cm³ |

| Corrosion Resistance | Excellent (esp. with anodizing) | Exceptional (esp. 316L) |

| Machinability | Easy, suitable for high-precision CNC | Medium |

| Thermal Conductivity | 190–210 W/m·K | 14–20 W/m·K |

| Cost (Material & Energy) | Lower | Higher |

| Sustainability | 98% recyclable, low energy footprint | 85% recyclable |

| Key Application | Flanges, valves, pump parts | Pressure piping, reactors |

6. Process Advantages & Customization Solutions

- High dimensional stability: Flanges made with precision aluminium metal casting offer tolerance as low as ±0.3 mm.

- Corrosion-resistant: Anodized or powder-coated surfaces provide effective protection in petrochemical and wastewater applications.

- Energy saving: Lightweight aluminium flanges reduce total equipment load and pumping/cooling system energy by 10–15% (based on field project data, 2023).

- Flexible sizing & shape: Complex geometries including bosses, ribs, and internal vanes can be integrated during the casting phase.

- Rapid prototyping capability: 3D printed sand molds cut lead time of custom flange development by up to 50%.

- Quality control & compliance: All products pass pressure and leakage tests to ISO 5208, hydraulic burst per ANSI/ASME B31.1, and dimension checks according to ISO 8062 CT7.

- Custom alloy specifications: Tailored alloy modifications for temperature, pressure, and chemical-resistance requirements.

7. YD Castings Flange: Process, Lead Time & Value-Added Services

- Rapid Response: Quotation within 24h; Drawing review within 36h; Sample lead time: 2–4 weeks for new moulds.

- Production Cycle: Standard batches (≤1000 pcs): 3–5 weeks. Fully traceable from raw material to shipment.

- Quality Assurance: Each batch accompanied with EN10204/3.1 certificates, CMM inspection, radiography, and salt-spray testing.

- After-sales Support: 18-month warranty, technical engineer support within 48 hours globally, spare parts inventory.

- Project: Sulfur Pipeline Retrofit – Saudi Aramco, 2023.

- Requirement: PN16 DN400 Flange, temperature: 180°C, resistant to H₂S condensate.

- Result: After replacing traditional SS flanges with aluminium metal casting flanges, total weight was reduced by 53%, maintenance cycles extended from 18 to 38 months, and total project costs lowered by 17% (validated by on-site client feedback and external SGS audit).

Customer Feedback

"Since switching to YD's aluminium metal casting flanges, we've observed significant reduction in both weight and rust accumulation, especially in our coastal desalination plants." — Project Engineer, Asia-Pacific Waterworks, 2023

8. Technical FAQ: Professional Terminologies Explained

- Q1: What is the difference between Green Sand Metal Casting and Aluminum Die Casting?

- Green Sand Metal Casting uses silica sand as mold material for economical, flexible production, ideal for low-medium volumes and large flanges. Aluminum Die Casting employs reusable steel molds for high speed, tight tolerance, and surface finish (down to Ra 1.5 μm) — preferred for high-volume standardized parts.

- Q2: Which aluminium alloy offers best strength-to-weight for flanges?

- AlSi10Mg is widely favored due to its balance of strength (yield ≥170 MPa), ductility, and corrosion resistance. A380/ADC12 is suitable for complex die cast geometries due to very good castability.

- Q3: What does “Pressure Rating PN10–PN40” mean?

- PN stands for “Pressure Nominal”, denoting maximum working pressure at 20°C; PN16 = 16 bar. Flanges with higher PN accommodate higher system pressure.

- Q4: Which standards do aluminium flanges typically comply with?

- Main standards: ISO 9001, ISO 8062 (casting tolerances), ANSI/ASME B16.5 (flange dimensions), ASTM B26 (aluminium alloys), EN 1092-1 (European flange standard).

- Q5: How is corrosion resistance tested?

- Laboratory ASTM B117 salt-spray test exposes the sample for 1000h; pass criteria: no severe pitting/rust (>98% covered surface remains intact).

- Q6: What is “CNC Machining” in flange production?

- After casting, CNC Machining refers to computer-controlled turning/milling (e.g. for bolt holes, sealing faces) — enabling each flange to meet CT7-CT8 tolerance grades (ISO 8062).

- Q7: How does YD Castings ensure dimensional accuracy?

- Coordinate Measuring Machine (CMM) is used to check ±0.05 mm critical dimensions post-machining; every lot is visually and dimensionally tested, and data is recorded per batch.

9. Delivery, Warranty & Customer Commitment

- Typical Lead Time: Patterns & prototypes: 2–3 weeks. Mass production (

- Warranty: 18 months, free replacement for manufacturing defects, full traceability for every batch.

- Technical Support: 48-hour engineer response worldwide; on-site support in >30 countries.

- Quality Certifications: ISO 9001:2015, CE (PED), TUV, major products also pass ANSI/ASME and FDA food-grade compliance where relevant.

- Major Partners: Sinopec, Veolia Water, ABB Hydraulics, Hitachi, Dow Chemical (verified partnerships; NDA where required).