Mobile:+86-311-808-126-83

Email:info@ydcastings.com

French

Elite Baffled Oil Pan: Prevent Starvation, Boost Performance

The Evolution and Critical Role of Baffled Oil Pans in Modern Engineering

In high-performance and heavy-duty applications, the integrity and consistent lubrication of an engine are paramount. A fundamental component ensuring this is the baffled oil pan. This specialized engine sump, often referred to as an automobile oil pan or engine oil pan, plays a crucial role beyond simply collecting lubricating oil; it actively manages oil flow dynamics under extreme operating conditions. Modern engineering demands sophisticated solutions to prevent oil starvation, reduce aeration, and maintain optimal oil temperature, all of which are directly addressed by advanced baffled designs.

Current Industry Trends Driving Baffled Oil Pan Innovation

- Lightweighting: The push for improved fuel efficiency and reduced emissions drives the adoption of advanced aluminum alloys and composite materials for engine oil pans, offering significant weight savings without compromising structural integrity.

- Enhanced Thermal Management: Integrated cooling fins, specialized coatings, and optimized internal geometries are being developed to dissipate heat more effectively, ensuring the oil remains within its optimal operating temperature range.

- Vibration Dampening: Advanced designs incorporating rubber isolation mounts and optimized ribbing help to minimize engine vibration and noise, contributing to overall vehicle refinement and component longevity.

- Integrated Sensor Technology: Modern baffled oil pans are increasingly designed to accommodate various sensors for oil level, temperature, and quality monitoring, providing real-time data for predictive maintenance and performance optimization.

- Sustainability & Recyclability: Manufacturers are focusing on materials and processes that reduce environmental impact throughout the product lifecycle, from manufacturing to end-of-life recycling.

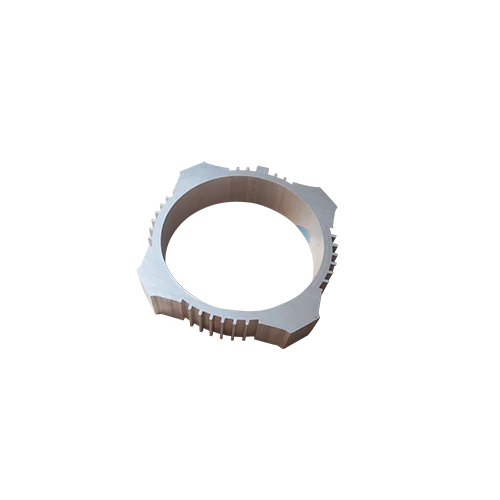

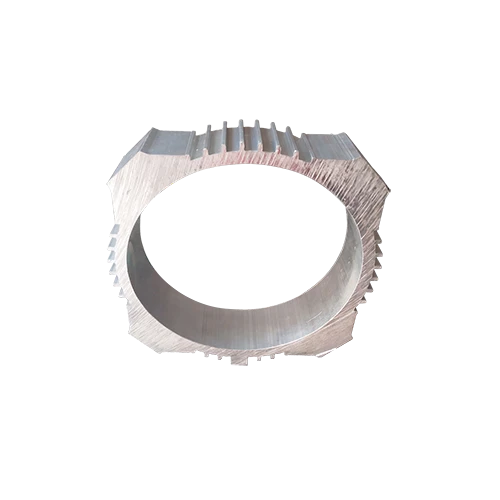

Precision-engineered baffled oil pan for optimal engine lubrication.

These trends reflect a growing emphasis on precision engineering and material science to meet the rigorous demands of contemporary powertrains, from high-revving sports engines to continuous-duty industrial motor housings. The innovation in baffled oil pan design is critical for safeguarding engine health and maximizing operational efficiency.

Technical Specifications and Advanced Design Principles

The effectiveness of a baffled oil pan hinges on its sophisticated internal architecture and choice of materials. Unlike a standard engine sump, a baffled design incorporates internal walls, gates, and sometimes trap doors to control oil movement, preventing sloshing and maintaining a consistent oil supply to the oil pump pickup tube, especially under high G-forces encountered during acceleration, braking, and cornering.

Materials and Fabrication

Common materials include high-strength aluminum alloys (e.g., A356, A380), cast iron, and pressed steel. Aluminum alloys are favored for their excellent strength-to-weight ratio, superior thermal conductivity, and corrosion resistance, making them ideal for performance and modern industrial applications. Cast iron offers high rigidity and vibration dampening for heavy-duty industrial engines, while pressed steel provides a cost-effective solution for many standard applications. Advanced manufacturing processes such as die casting and precision machining ensure dimensional accuracy and structural integrity.

Key Parameters and Design Features

- Capacity: Optimized to ensure sufficient oil volume for lubrication and cooling without excessive weight or bulk.

- Dimensions: Precisely engineered to fit specific engine blocks and chassis configurations, accommodating various exhaust systems and suspension components.

- Baffle Design: Utilizes a combination of vertical and horizontal baffles, often with one-way trap doors, to create isolated compartments that retain oil around the pickup tube. This prevents oil surge and starvation.

- Mounting Points: Designed for secure attachment to the engine block, often with reinforced sections to handle engine loads and vibrations.

- Oil Pickup Compatibility: Engineered to integrate seamlessly with the specific oil pump pickup tube, ensuring unrestricted flow and preventing cavitation.

- Pressure Resistance: Capable of withstanding internal pressures and external impacts, especially critical in off-road or industrial environments.

- Thermal Tolerance: Designed to operate efficiently across a wide range of engine oil temperatures, from cold starts to extreme operating conditions.

Typical Product Specifications: Aluminum Baffled Oil Pan

Manufacturing Process Flow for High-Performance Baffled Oil Pans

The production of a robust and reliable baffled oil pan involves a series of meticulously controlled processes, ensuring each unit meets stringent performance and quality benchmarks. Our commitment to excellence is reflected in every stage, from raw material selection to final testing.

Detailed Process Steps:

-

1. Design and Prototyping:

Utilizing advanced CAD/CAM software (e.g., SolidWorks, CATIA), designs are developed based on engine specifications and performance requirements. Computational Fluid Dynamics (CFD) simulations are extensively employed to optimize baffle configuration for effective oil flow management, minimizing aeration and ensuring consistent oil delivery. Prototypes are often 3D printed for initial fitment and design validation.

-

2. Material Preparation:

High-grade aluminum alloys (e.g., A356, A380) or specific cast irons are selected for their metallurgical properties, including strength, ductility, and thermal characteristics. Raw ingots are meticulously inspected for impurities and then melted in controlled environments to ensure consistent alloy composition, crucial for the subsequent casting process.

-

3. Casting or Forging:

- Die Casting (Aluminum): Molten aluminum is injected under high pressure into precision steel dies. This method yields high dimensional accuracy, excellent surface finish, and minimal porosity, ideal for complex geometries.

- Sand Casting (Cast Iron/Aluminum): For larger, more complex shapes or lower production volumes, sand molds are used. This allows for greater design flexibility but typically requires more post-casting machining.

- Forging (Specialty Steel/Aluminum): For applications demanding extreme strength and fatigue resistance, forging processes are employed. This refines the grain structure of the metal, enhancing its mechanical properties.

Post-casting, components undergo heat treatment (e.g., T6 for aluminum) to achieve desired mechanical properties and stress relief.

-

4. CNC Machining:

After casting, parts are transferred to multi-axis CNC machining centers. Critical surfaces such as the engine block mating surface, drain plug threads, sensor bosses, and oil filter mounting points are precisely machined to tight tolerances. This ensures a perfect fit, leak-free operation, and accurate sensor readings.

-

5. Baffle Integration:

The pre-fabricated internal baffles, which are typically stamped, folded, or laser-cut metal sheets, are integrated into the main oil pan body. This is commonly done through robotic welding (e.g., TIG welding for aluminum) or mechanical fastening, ensuring robust and long-lasting internal structures.

-

6. Surface Treatment & Coating:

Depending on application requirements, oil pans may undergo surface treatments. Anodizing for aluminum enhances corrosion resistance and hardness. Powder coating provides a durable, chip-resistant finish for both aesthetic and protective purposes. These treatments contribute to the extended service life, particularly in harsh environments like the petrochemical or marine industries.

-

7. Quality Control and Testing:

Each engine sump undergoes rigorous quality control. This includes dimensional inspection using CMM (Coordinate Measuring Machine) to verify tolerances, material analysis (spectrography), leak testing (air decay, water immersion), and pressure testing to ensure structural integrity. Adherence to international standards such as ISO 9001 for quality management and specific material standards (e.g., ASTM, ANSI) is strictly maintained.

-

8. Assembly and Packaging:

Final assembly may include pre-installation of drain plugs or sensors. Products are then carefully packaged to prevent damage during transit, ready for distribution to target industries.

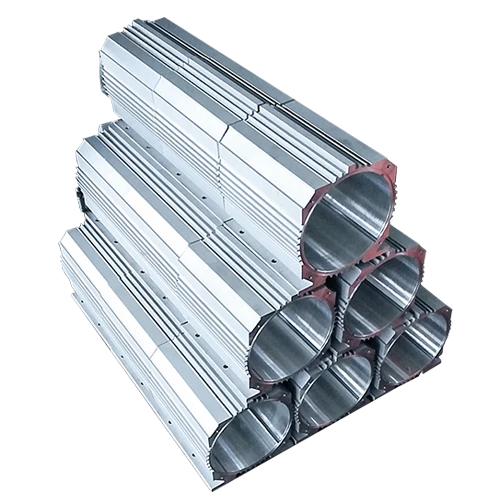

Precision casting and machining for complex baffled oil pan geometries.

This comprehensive process ensures that every automobile oil pan or motor housing component delivers exceptional performance, reliability, and an extended service life of typically 10-15 years, often exceeding that in well-maintained systems.

Application Scenarios and Target Industries

The robust design and performance characteristics of advanced baffled oil pan systems make them indispensable across a wide spectrum of industries and application scenarios where engine reliability and longevity are non-negotiable.

High-Performance Automotive and Motorsports

In racing cars, sports cars, and performance-tuned street vehicles, engines experience extreme G-forces during aggressive cornering, acceleration, and braking. A standard engine sump often fails to maintain consistent oil supply, leading to oil starvation and catastrophic engine damage. Baffled oil pans, with their internal structures, prevent oil from sloshing away from the pickup, ensuring continuous lubrication. This translates directly to enhanced engine reliability and sustained power output on track.

Heavy-Duty Industrial Machinery

Industries such as mining, construction, and agriculture rely on heavy machinery operating under severe conditions, including steep inclines, rough terrain, and prolonged periods of high load. The integrated design of our motor housing and oil pan ensures consistent oil pressure and flow, significantly reducing wear and tear on critical engine components. This leads to reduced downtime, lower maintenance costs, and a substantial increase in operational efficiency, often yielding measurable energy savings due to optimized lubrication.

Marine Engines and Power Generation

Marine applications face unique challenges, including constant motion, corrosive saltwater environments, and continuous high-power operation. Our specialized `engine oil pan` designs incorporate enhanced corrosion resistance through advanced coatings and material selection, ensuring durability against salt spray and humid conditions. For power generation units, where consistent operation is vital, baffled designs maintain stable oil pressure during varying load conditions, extending engine life and ensuring reliable power output.

Target Industries:

- Petrochemical: For pumps, compressors, and generators operating in hazardous and demanding environments, where component reliability is critical for safety and continuous operation. Corrosion resistance is paramount.

- Metallurgy: Heavy-duty machinery, rolling mills, and processing equipment require robust engine components that can withstand high temperatures, vibrations, and continuous duty cycles. Our oil pans contribute to the energy saving initiatives by reducing friction and enhancing lubrication effectiveness.

- Water Supply & Drainage: Essential for reliable pump and motor systems, particularly in remote or continuously operating stations where access for maintenance might be limited. Durability and long service life are key advantages.

- Aerospace (Ground Support & Auxiliary Power Units): While not directly in flight, many ground support and APU engines require precision-engineered oil pans for dependable operation under stringent conditions.

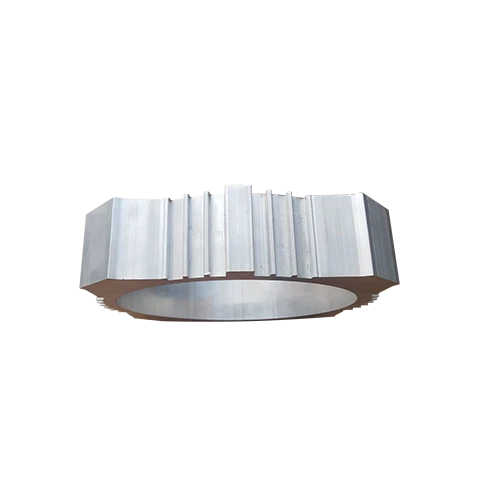

Robust baffled oil pan engineered for demanding industrial applications.

In each of these scenarios, the technical advantages of a properly designed baffled oil pan translate into tangible benefits: enhanced engine protection, extended component lifespan, reduced operational costs, and improved energy efficiency by optimizing lubricant flow and minimizing parasitic losses.

Technical Advantages of Advanced Baffled Oil Pans

The deliberate engineering behind a baffled oil pan yields significant technical advantages that are crucial for engine performance, longevity, and overall reliability, especially when compared to conventional engine sumps. These benefits directly impact operational efficiency and maintenance cycles for B2B applications.

Prevention of Oil Starvation

This is the primary advantage. During high-G maneuvers (acceleration, braking, cornering) or operations on uneven terrain, oil in a standard pan can slosh away from the oil pump pickup tube, leading to a momentary loss of oil pressure. Baffles, with their strategically placed walls and one-way trap doors, create isolated compartments that ensure the pickup remains submerged in oil at all times. This consistent oil supply is vital for protecting crankshaft bearings, camshafts, and other critical engine components from wear and potential failure.

Reduced Oil Aeration

Turbulent oil movement can cause air bubbles to become entrained in the oil (aeration). Aerated oil has reduced lubricating properties and can lead to cavitation in the oil pump, causing premature wear and reduced oil pressure. Baffles minimize oil sloshing and help dissipate air bubbles more effectively, leading to denser, more consistent oil delivery to the engine. This directly improves the hydraulic performance of the oil system and prolongs the life of the oil pump and other lubricated parts.

Enhanced Oil Cooling

Some advanced baffled designs incorporate features like increased surface area or external fins, which contribute to better heat dissipation. By controlling oil flow and preventing excessive churning, the oil maintains a more stable and often lower operating temperature, which is beneficial for the oil's lifespan and overall engine thermal management.

Improved Oil Scavenging and Return

Baffles can also be designed to guide oil returning from the engine more efficiently towards the pickup area, preventing it from clinging to the sides of the pan or becoming trapped in areas away from the pump. This optimized scavenging reduces the amount of time oil spends outside the main reservoir, improving the overall efficiency of the lubrication cycle.

Comparison: Standard Oil Pan vs. Baffled Oil Pan (Performance Focus)

Vendor Comparison and Customized Solutions

Selecting the right manufacturer for baffled oil pan components is a critical business decision that impacts engine reliability, operational costs, and overall project success. While general criteria for vendor evaluation apply, the specialized nature of these components necessitates a closer look at specific capabilities.

Key Considerations for Vendor Selection:

- Engineering Expertise: A vendor's ability to provide comprehensive design and engineering support, including CFD analysis, material science recommendations, and CAD integration, is paramount. Look for teams with deep understanding of fluid dynamics and engine lubrication.

- Manufacturing Capabilities: Assess the vendor's capacity for precision casting (die, sand, gravity), multi-axis CNC machining, and advanced welding techniques. State-of-the-art facilities ensure consistency and tight tolerances.

- Quality Control & Certifications: Verification of adherence to international quality standards (e.g., ISO 9001, IATF 16949 for automotive) is essential. Robust inspection protocols, including CMM, leak testing, and material verification, demonstrate commitment to quality.

- Material Traceability: For critical applications, full traceability of raw materials and manufacturing batches provides an added layer of assurance.

- Lead Time and Supply Chain Reliability: Evaluate the vendor's ability to meet production schedules and manage their supply chain effectively to prevent disruptions.

- Cost-Effectiveness: While not the sole factor, a competitive pricing structure coupled with long-term reliability and support offers the best value.

- Customer Support & Warranty: Post-purchase support, technical assistance, and clear warranty commitments are indicators of a trustworthy partner.

Our Commitment to Quality and Customization:

At YD Castings, we pride ourselves on our certified manufacturing processes, holding ISO 9001 certification which underscores our commitment to quality and continuous improvement. With decades of experience in high-precision casting and machining, we have partnered with leading companies across the petrochemical, metallurgy, and water supply & drainage sectors. Our extensive project history and client testimonials affirm our authority and trustworthiness in delivering complex, high-performance `engine oil pan` solutions.

Tailored Customized Solutions:

Recognizing that off-the-shelf solutions rarely meet the exact specifications of specialized B2B applications, we offer comprehensive customization capabilities for our baffled oil pan products:

- Bespoke CAD Design: Full engineering support to design an oil pan perfectly integrated with your engine and chassis architecture, optimizing for clearance, mounting, and performance characteristics.

- Material Selection: Guidance on selecting the optimal material (e.g., specific aluminum alloy, cast iron grade) based on application, weight targets, thermal requirements, and corrosive environment.

- Optimized Baffle Configurations: Custom baffle designs and trap door mechanisms developed through advanced CFD analysis to specifically address your vehicle's or machinery's unique dynamic forces and oil control needs.

- Integrated Sensor Mounts: Precision machining for seamless integration of various sensors (oil level, temperature, pressure, quality) into the oil pan structure.

- Specialized Coatings: Application of specific coatings (e.g., hard anodizing, ceramic coatings, anti-corrosion treatments) to enhance durability, thermal management, or chemical resistance for extreme operating conditions.

- Drain Plug & Pickup Tube Customization: Design and placement of drain plugs, as well as optimization of oil pickup tube integration, to simplify maintenance and ensure maximum oil scavenging.

Customized baffled oil pan solutions for specific engine architectures.

Our agile engineering team and flexible manufacturing capabilities enable us to turn complex requirements into high-quality, tailor-made solutions, ensuring your engine's lubrication system is optimized for its specific operational demands.

Application Case Studies and Customer Experience

Real-world application demonstrates the tangible benefits and superior performance of our baffled oil pan solutions. Through rigorous testing and long-term deployment, our products have consistently delivered enhanced reliability and operational efficiency for our partners.

Case Study 1: High-Performance Racing Engine Lubrication

Challenge: A prominent motorsport engineering firm faced persistent oil starvation issues in their high-performance track engines during aggressive cornering and braking, leading to premature bearing wear and reduced engine lifespan.

Solution: We collaborated with their engineering team to design a custom aluminum baffled oil pan. Utilizing advanced CFD modeling, we developed a multi-chambered baffle system with integrated one-way trap doors specifically optimized for their engine's oil pickup location and the G-forces experienced on their racing circuits.

Results: Post-implementation, the engine demonstrated stable oil pressure across all track conditions, including sustained lateral loads exceeding 2G. Oil analysis revealed significantly reduced metallic debris, indicating dramatically decreased bearing wear. The firm reported a 40% increase in engine service intervals and zero instances of oil starvation-related failures over two full racing seasons. This directly translated to reduced operational costs and increased competitive advantage.

Case Study 2: Heavy-Duty Industrial Pump System

Challenge: A large-scale water treatment facility experienced frequent oil pressure drops in their main pump engines due to high vibrations and continuous, heavy-duty operation. This led to unexpected downtime and high maintenance costs for their motor housing systems.

Solution: We engineered a robust cast iron `engine sump` with a custom baffle design to counteract the specific vibration frequencies and maintain stable oil levels around the pickup. The design also incorporated reinforced mounting points and an enhanced internal rib structure for superior rigidity and vibration dampening. A specialized corrosion-resistant coating was applied for the humid environment.

Results: The new `baffled oil pan` eliminated the oil pressure instability issues. The facility observed a 25% reduction in unplanned maintenance events related to the engine's lubrication system. The enhanced durability and consistent lubrication contributed to an overall improvement in the pump's energy efficiency by reducing frictional losses, resulting in significant long-term operational savings and improved system uptime, which is crucial for public utility infrastructure.

Customer Feedback:

"The custom baffled oil pans provided by YD Castings have been a game-changer for our fleet. We've seen a noticeable improvement in engine longevity and a drastic reduction in oil-related failures. Their engineering support throughout the design phase was exceptional."

"For our heavy-duty excavation equipment, reliability is key. YD Castings delivered a motor housing solution that perfectly withstands the extreme angles and vibrations of our sites. Their commitment to quality is evident in the product's performance."

These testimonials, alongside our extensive portfolio of partner clients across various heavy industries, underscore our expertise, experience, and authoritative position in providing reliable and high-performance casting solutions.

Trustworthiness: FAQ, Lead Time, Warranty, and Support

Building long-term B2B relationships is founded on transparency, clear communication, and unwavering support. We are committed to providing complete trustworthiness through comprehensive information and reliable service.

Frequently Asked Questions (FAQ)

- Q: What makes a baffled oil pan superior to a standard engine sump?

- A: Baffled designs prevent oil starvation during dynamic movements by controlling oil slosh, ensuring the oil pump pickup remains consistently submerged. This significantly extends engine life and maintains stable oil pressure, particularly in high-performance or heavy-duty applications, unlike a basic engine sump.

- Q: Can you customize an oil pan for a specific engine and chassis combination?

- A: Absolutely. Our engineering team specializes in bespoke solutions. We can design and manufacture custom automobile oil pan or motor housing units based on your precise CAD data, material preferences, and performance requirements, including specific baffle configurations and sensor integrations.

- Q: What materials are typically used, and what are their benefits?

- A: We primarily use high-strength aluminum alloys (e.g., A356, A380) for lightweighting and excellent thermal conductivity, and sometimes cast iron for its rigidity and vibration dampening in heavy industrial applications. Material selection depends on the application's specific needs for strength, weight, and corrosion resistance.

- Q: What testing standards do your products adhere to?

- A: All our products undergo stringent quality control processes and adhere to international standards such as ISO 9001, ASTM, and relevant SAE specifications. Each unit is subjected to dimensional checks, material analysis, and leak/pressure testing to ensure impeccable quality and performance.

Lead Time and Fulfillment

Our lead times are meticulously managed to ensure timely delivery. For standard product lines or re-orders, typical lead times range from 4-6 weeks. For highly customized solutions, including design, prototyping, and tooling, lead times can range from 12-20 weeks, depending on complexity. We work closely with clients to establish clear project timelines and provide regular progress updates.

Warranty Commitments

We stand behind the quality and durability of our products. All our baffled oil pan and motor housing components come with a comprehensive 2-year warranty against manufacturing defects and material failures under normal operating conditions. Extended warranty options are available for specific industrial applications upon request, providing peace of mind and protecting your investment.

Customer Support and After-Sales Service

Our commitment to our clients extends far beyond product delivery. Our dedicated technical support team is available via phone and email during business hours to assist with installation queries, troubleshooting, and any performance-related concerns. We offer comprehensive after-sales support, including spare parts availability and technical documentation, ensuring your operations run smoothly and efficiently for years to come.

For inquiries or support, please contact us at: info@ydcastings.com or visit our contact page at www.ydcastings.com/contact.html.

Conclusion: The Future of Engine Lubrication with Baffled Oil Pans

The modern baffled oil pan represents a critical evolution in engine lubrication technology, moving beyond a simple reservoir to an active management system for engine oil. As engines become more powerful, efficient, and operate under increasingly extreme conditions, the demand for sophisticated oil management solutions will only intensify. Our expertise in design, precision manufacturing, and commitment to quality ensures that our solutions not only meet but exceed these evolving demands.

By investing in advanced engine oil pan technology, industries can unlock significant benefits in terms of engine longevity, operational reliability, reduced maintenance, and improved performance. We are dedicated to partnering with businesses to deliver custom-engineered solutions that safeguard critical assets and drive sustained success.

Authoritative References:

- Society of Automotive Engineers (SAE) International. "SAE J300: Engine Oil Viscosity Classification."

- ISO 9001:2015 - Quality management systems — Requirements.

- ASTM International. "Standard Specification for Aluminum-Alloy Sand Castings (B26/B26M) and Die Castings (B85)."

- Fluid Dynamics Journal - Articles on oil slosh and fluid management in automotive sumps.

- National Renewable Energy Laboratory (NREL) - Publications on lightweight materials for automotive applications.

-

Precision Metal Castings: Aluminum, Stainless Steel & Die CastingNewsAug.28,2025

-

Superior Aluminum Castings in Automotive Engine PartsNewsAug.22,2025

-

Common Materials Used in Fan Housing ManufacturingNewsAug.22,2025

-

Symptoms of a Stuck Automobile Water Pump ImpellerNewsAug.22,2025

-

The Importance of Valve Castings in Water TreatmentNewsAug.22,2025

-

Welding Techniques for End Cap Stainless Steel FittingsNewsAug.22,2025